Integrated broadband antenna and manufacturing method thereof

A production method and wide-band technology, applied in the directions of antenna grounding device, antenna support/mounting device, radiation element structure, etc., can solve problems such as increased antenna loss, impedance mismatch, and reduced bandwidth, and achieve reduced transmission distance, improve reliability, and reduce loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] see Figure 1 to Figure 11 , as shown in the figure, the present invention provides a method for manufacturing an integrated broadband antenna, which at least includes the following steps:

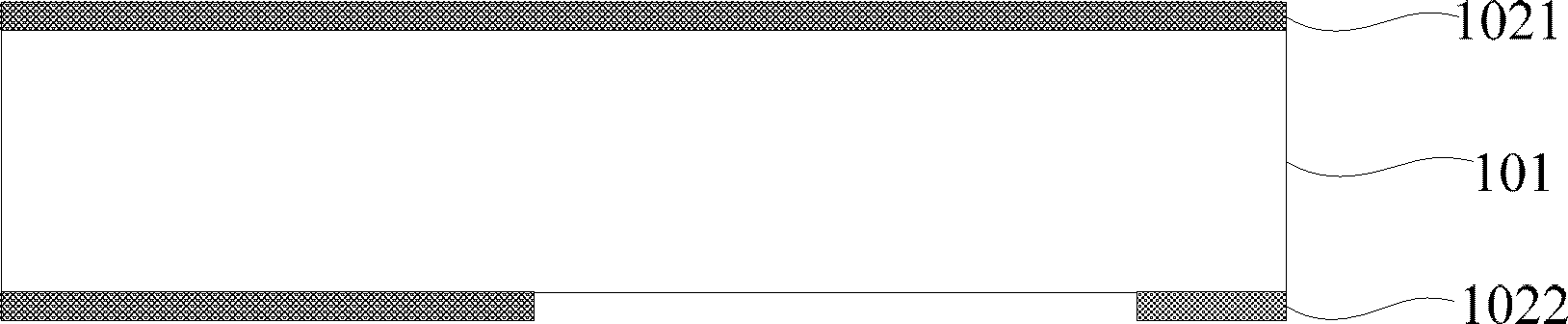

[0052] Such as figure 1 As shown, step 1) is first carried out, providing a Si substrate 101, and forming upper SiO on the upper and lower surfaces of the Si substrate. 2 Layer 1021 and lower SiO 2 layer 1022, under the SiO 2 A window is etched in layer 1022;

[0053] In this embodiment, the Si substrate 101 is oxidized by a thermal oxidation method to obtain the upper SiO 2 Layer 1021 and lower SiO 2 layer 1022, the upper SiO 2 Layer 1021 and lower SiO 2 Layers 1022 each have a thickness of 2 μm. Using BOE wet etch under the SiO 2 A window is etched in layer 1022 .

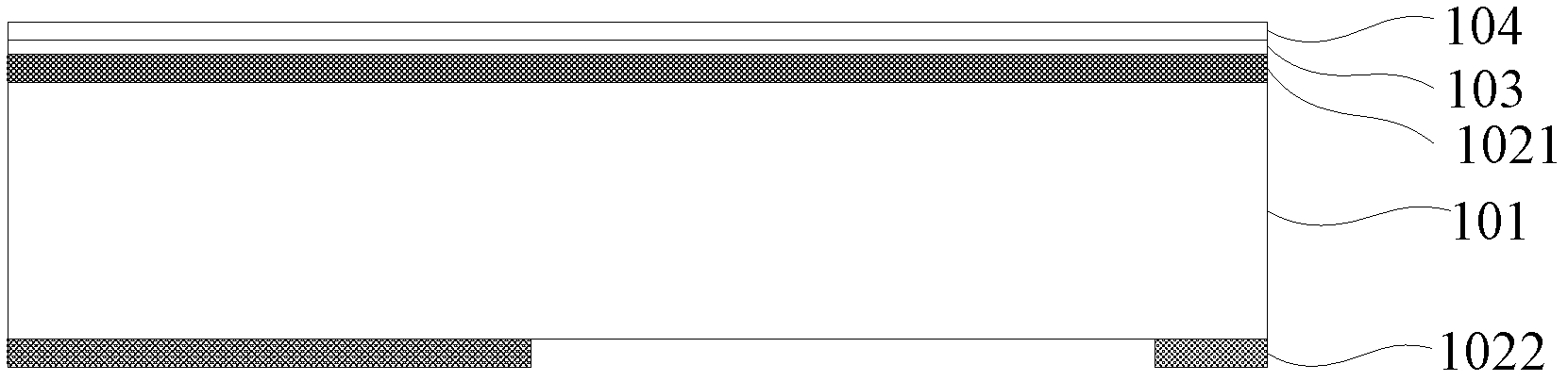

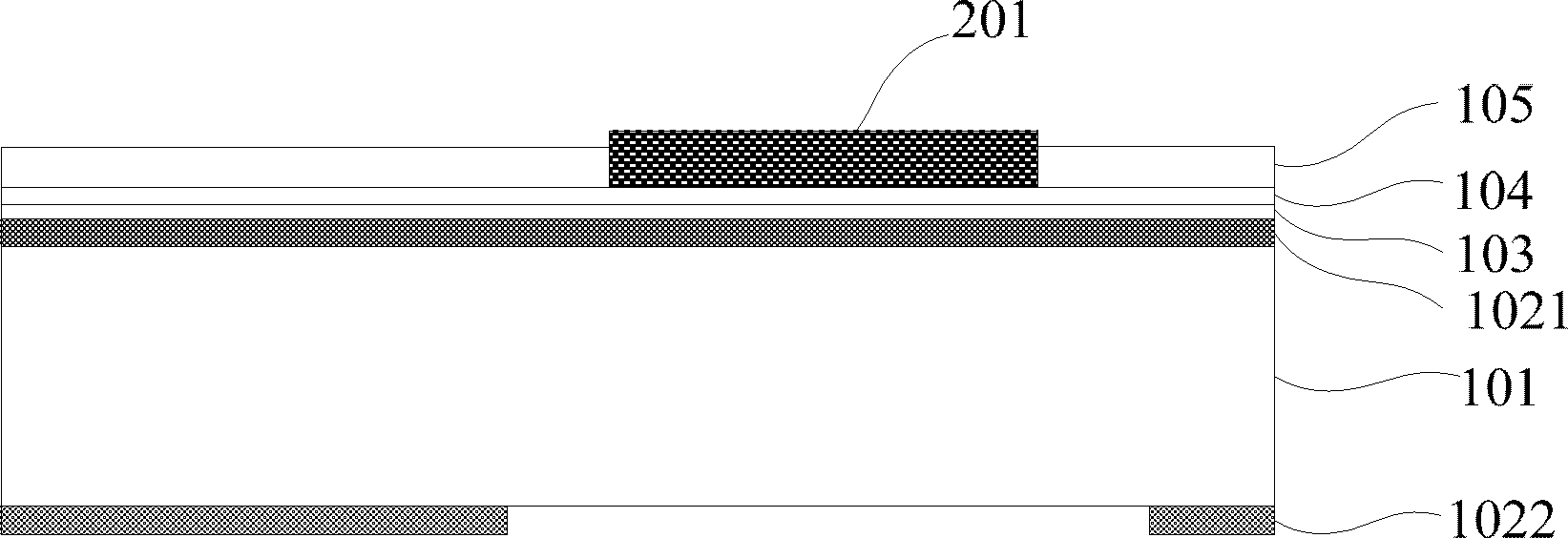

[0054] Such as Figure 2 ~ Figure 5b shown, and then proceed to step 2), on the SiO 2 Form the first seed layers 103-104 on the layer 1021, form a photoresist 201 on the first seed layer corresponding to th...

Embodiment 2

[0063] see Figure 10a ~ Figure 10c , the present invention also provides an integrated broadband antenna, at least including: a support structure, the support structure has a dielectric cavity 115; The region has a groove structure 106; solder balls 107, welded to the ground plane and used as the lead-out end of the ground plane; an organic dielectric layer 108, covering the ground plane and the groove structure 106; pattern antenna 111 ˜113 includes an antenna main body located in a vertical area on the dielectric cavity 115 and combined with the organic dielectric layer 108 and a feeder extending from the antenna main body toward the solder ball 107 . It should be noted that the shape of the pattern antennas 111 - 113 may be rectangular, circular, elliptical, polygonal, clothoid, or other desired shapes. Since the dielectric constant of the dielectric cavity 115 is the dielectric constant of vacuum or air, and the value is about 1, the dielectric substrate of the antenna c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com