Treatment method for recycling hydrofluoric acid waste liquor

A waste liquid recovery and treatment method technology, applied in the direction of fluorine/hydrogen fluoride, etc., can solve the problems of high waste water treatment costs, waste of hydrofluoric acid recovery and reuse, high cost of chemical agents, etc., to achieve both environmental benefits and reduce The effect of processing costs and reducing cost expenditures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

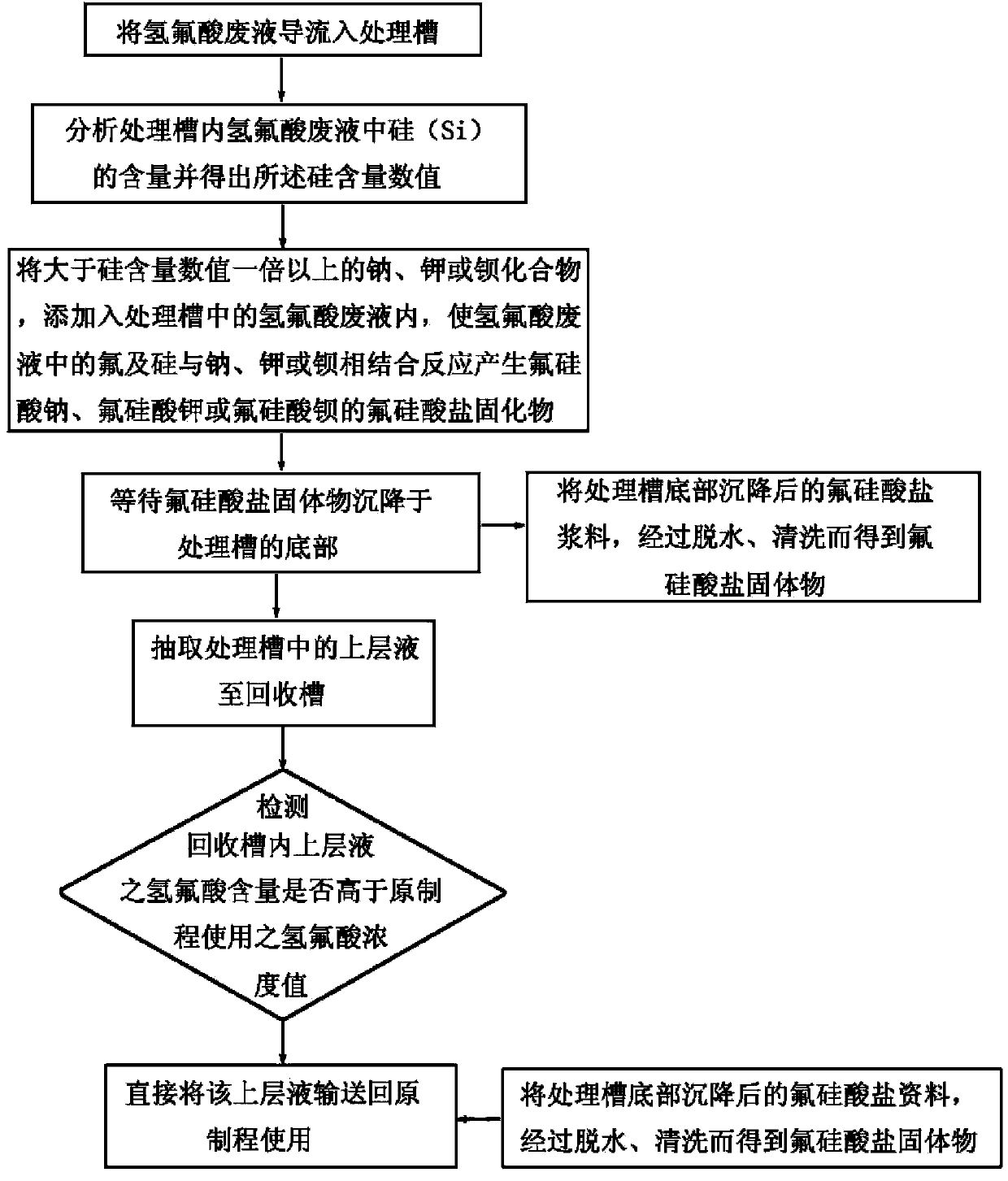

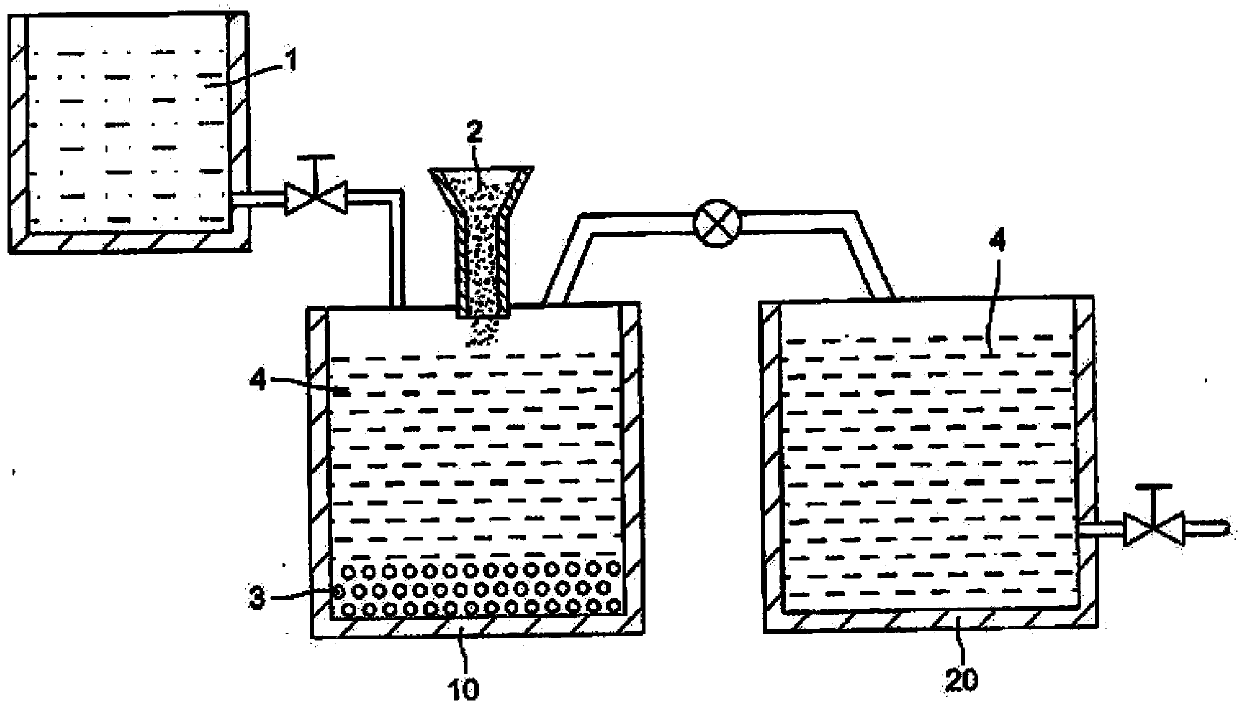

[0038] see figure 1 and figure 2 Shown, the treatment method that hydrofluoric acid waste liquid of the present invention reclaims reuse, its step comprises:

[0039] A, guide hydrofluoric acid (HF) waste liquid 1 into treatment tank 10;

[0040] B, analyze the content of silicon (Si) in the hydrofluoric acid waste liquid 1 in the treatment tank 10, and draw described silicon content numerical value;

[0041] c. Add sodium compound 2 which is more than twice the value of silicon content into the hydrofluoric acid waste liquid 1 in the treatment tank 10, so that the fluorine and silicon in the hydrofluoric acid waste liquid 1 are combined with sodium to generate fluorosilicon Sodium acid solids (Na 2 SiF 6 (s))3;

[0042] d, waiting for the sodium fluorosilicate solid 3 to settle at the bottom of the treatment tank 10;

[0043] e, extract the supernatant liquid 4 in the treatment tank 10 to the recovery tank 20;

[0044] f. Check whether the hydrofluoric acid content of...

Embodiment 2

[0059] see figure 1 and figure 2 Shown, the treatment method that hydrofluoric acid waste liquid of the present invention reclaims reuse, its step comprises:

[0060] A, guide hydrofluoric acid (HF) waste liquid 1 into treatment tank 10;

[0061] B, analyze the content of silicon (Si) in the hydrofluoric acid waste liquid 1 in the treatment tank 10, and draw described silicon content numerical value;

[0062] c. Add potassium compound 2, which is more than twice the value of silicon content, into the hydrofluoric acid waste liquid 1 in the treatment tank 10, so that the fluorine and silicon in the hydrofluoric acid waste liquid 1 are combined with potassium to generate fluorosilicon Potassium acid solids (K 2 SiF 6 (s))3;

[0063] d, waiting for the potassium fluorosilicate solid 3 to settle at the bottom of the treatment tank 10;

[0064] e, extract the supernatant liquid 4 in the treatment tank 10 to the recovery tank 20;

[0065] f. Check whether the hydrofluoric ac...

Embodiment 3

[0080] see figure 1 and figure 2 Shown, the treatment method that hydrofluoric acid waste liquid of the present invention reclaims reuse, its step comprises:

[0081] A, guide hydrofluoric acid (HF) waste liquid 1 into treatment tank 10;

[0082] B, analyze the content of silicon (Si) in the hydrofluoric acid waste liquid 1 in the treatment tank 10, and draw described silicon content numerical value;

[0083] c. Add the barium compound 2 which is more than twice the silicon content value into the hydrofluoric acid waste liquid 1 in the treatment tank 10, so that the fluorine and silicon in the hydrofluoric acid waste liquid 1 are combined with barium to generate fluorosilicon Barium acid solid (BaSiF 6 (s))3;

[0084] d, waiting for the barium fluorosilicate solid 3 to settle at the bottom of the treatment tank 10;

[0085] e, extract the supernatant liquid 4 in the treatment tank 10 to the recovery tank 20;

[0086] f. Check whether the hydrofluoric acid content of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com