Method for preparing orderly gallium nitride nano pillar array with ultraviolet soft imprinting

A gallium nitride nanometer and soft embossing technology, which is applied in the direction of nanotechnology, optomechanical equipment, photoplate making process of pattern surface, etc., can solve the problems that there are no nanostructure light-emitting diodes, etc., to improve light extraction efficiency and improve Internal Quantum Efficiency, Effect of Internal Quantum Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

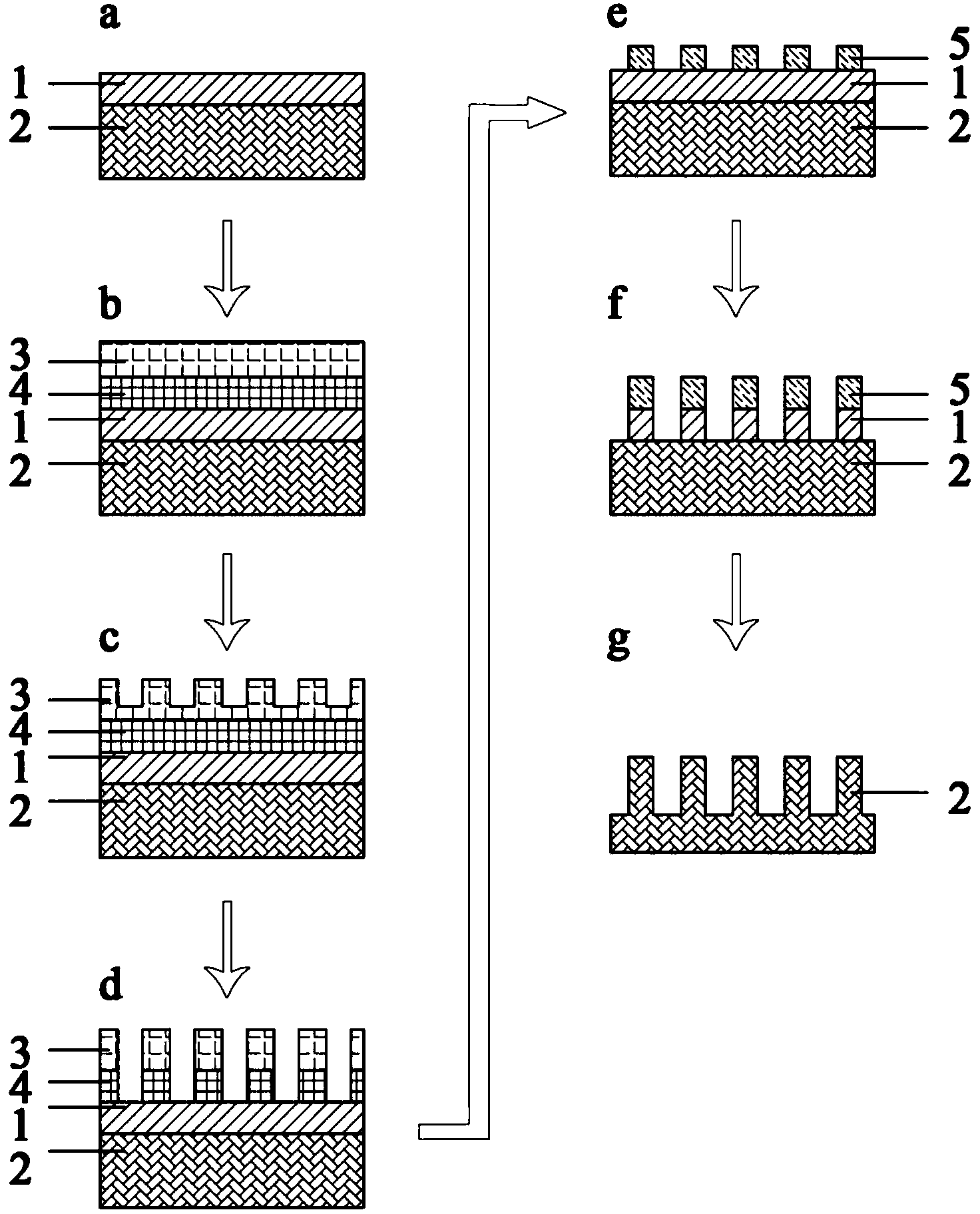

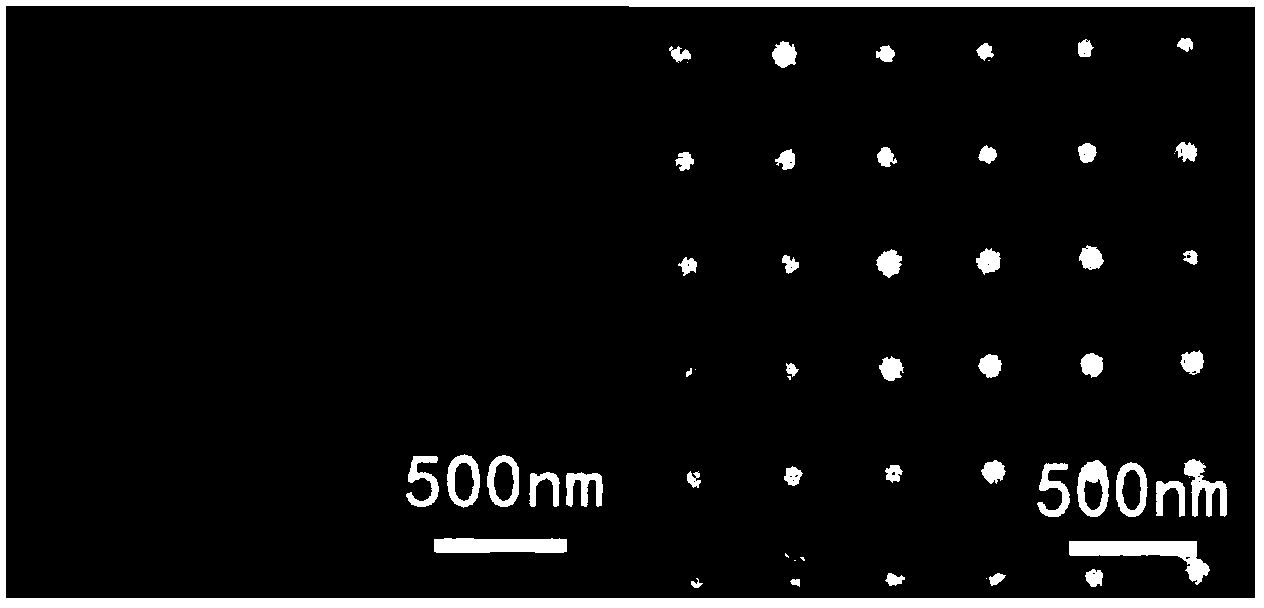

[0032] The present invention prepares a large-area and low-defect gallium nitride nanocolumn (hole) array through an ultraviolet soft imprinting technique, and uses reactive ion etching to control the diameter of the nanocolumn (hole) in the dielectric layer, thereby Realize controllable diameter of gallium nitride nanopillars (holes).

[0033] figure 1 Among them, 1 represents silicon dioxide or silicon nitride, 2 represents gallium nitride substrate, 3 represents UV curing adhesive, 4 represents PMMA, and 5 represents metal nickel or chromium. figure 1 a-1f represents each technological process. Figure 5 11 represents gallium nitride, 12 represents n-type gallium nitride, 13 represents indium gallium nitrogen quantum well, and 14 represents p-type gallium nitride. The luminous intensity of the gallium nitride nanocolumn (hole) array is greatly improved, especially the internal quantum efficiency is improved, and it is suitable for preparing a nanocolumn (hole) type light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com