Environment-friendly rustproof cleaning agent

An environmentally friendly, cleaning agent technology, applied in the field of cleaning agents, can solve the problems of increasing energy consumption, increasing production costs, secondary pollution, etc., and achieve the effect of preventing continuous corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

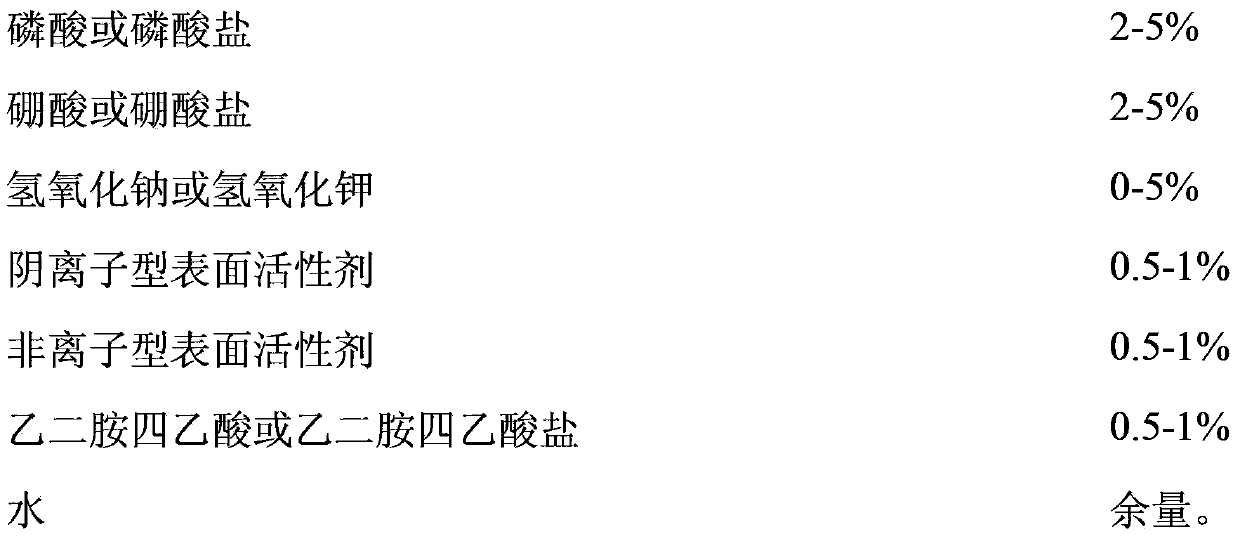

Method used

Image

Examples

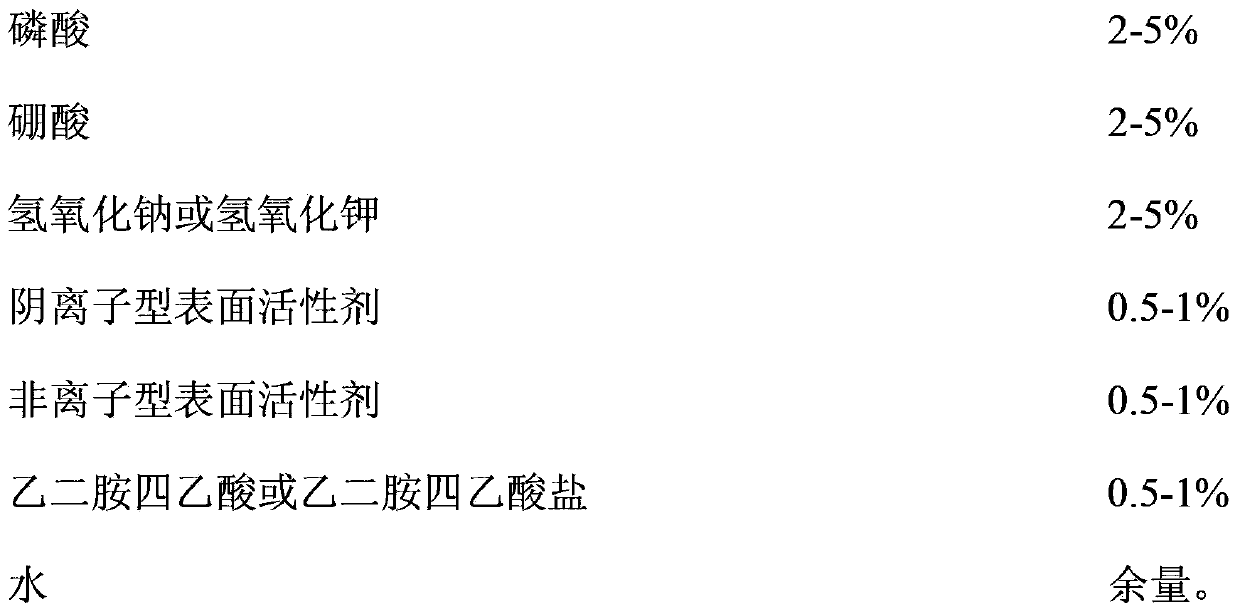

Embodiment 1

[0030] The preparation method of 1# environment-friendly anti-rust cleaning agent:

[0031] Weigh 3kg of phosphoric acid, 3kg of boric acid, 3kg of sodium hydroxide, 0.8kg of sodium lauryl sulfate, 0.8kg of sorbitan monooleate polyoxyethylene ether (Tween-80), 0.8kg of ethylenediaminetetra Add disodium acetate successively to 88.6kg of water and stir until all ingredients are completely dissolved and there is no sediment at the bottom of the container.

[0032] Use 1# environment-friendly anti-rust cleaning agent, clean it according to GB / T2361, and carry out the anti-rust damp heat test result: 72 hours, level 1.

[0033] Use the 1# environment-friendly anti-rust cleaning agent to do the liquid phase corrosion test according to the test method of GB / T11143-2008: the result is qualified.

[0034] After diluting the 1# environment-friendly anti-rust cleaning agent with water 20 times, clean the 45# steel processed with the emulsion. After 48 hours, there is no visible rust on ...

Embodiment 2

[0036] The preparation method of 2# environment-friendly anti-rust cleaning agent:

[0037] Weigh 2kg sodium phosphate, 5kg boric acid, 2.5kg sodium hydroxide, 0.5kg sodium dodecylbenzenesulfonate, 1kg lauryl polyoxyethylene (9) ether, 0.5kg ethylenediaminetetraacetic acid, add 88.5kg Stir in water until all ingredients are completely dissolved and there is no sediment at the bottom of the container.

Embodiment 3

[0039] The preparation method of 3# environment-friendly anti-rust cleaning agent:

[0040] Weigh 5kg of phosphoric acid, 2kg of potassium tetraborate, 2kg of potassium hydroxide, 1kg of sodium secondary alkyl sulfonate SAS60, 0.5kg of nonylphenol polyoxyethylene (10) ether, and 1kg of tetrasodium ethylenediaminetetraacetic acid, and add them in sequence Take 88.5kg of water and stir until all ingredients are completely dissolved and there is no sediment at the bottom of the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com