Coronatine aqueous solution and preparation method thereof

A technology of coronatin and water preparation, which is applied in the field of coronatin water preparation and its preparation, and can solve the problems of no reports of coronatin preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the preparation of coronatin

[0038] The non-polar macroporous adsorption resin HPD300 used in the examples was purchased from Cangzhou Baoen Adsorption Material Co., Ltd.

[0039] Silica gel (model ZCX.II, particle size 100-200 mesh) was purchased from Qingdao Ocean Chemical Factory.

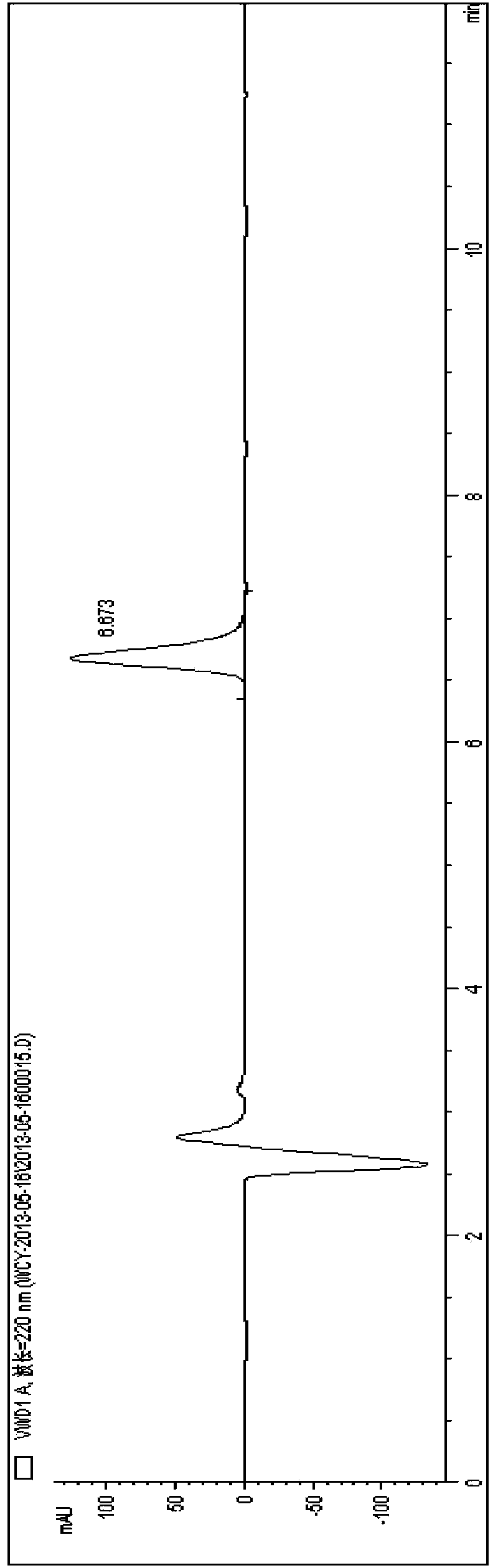

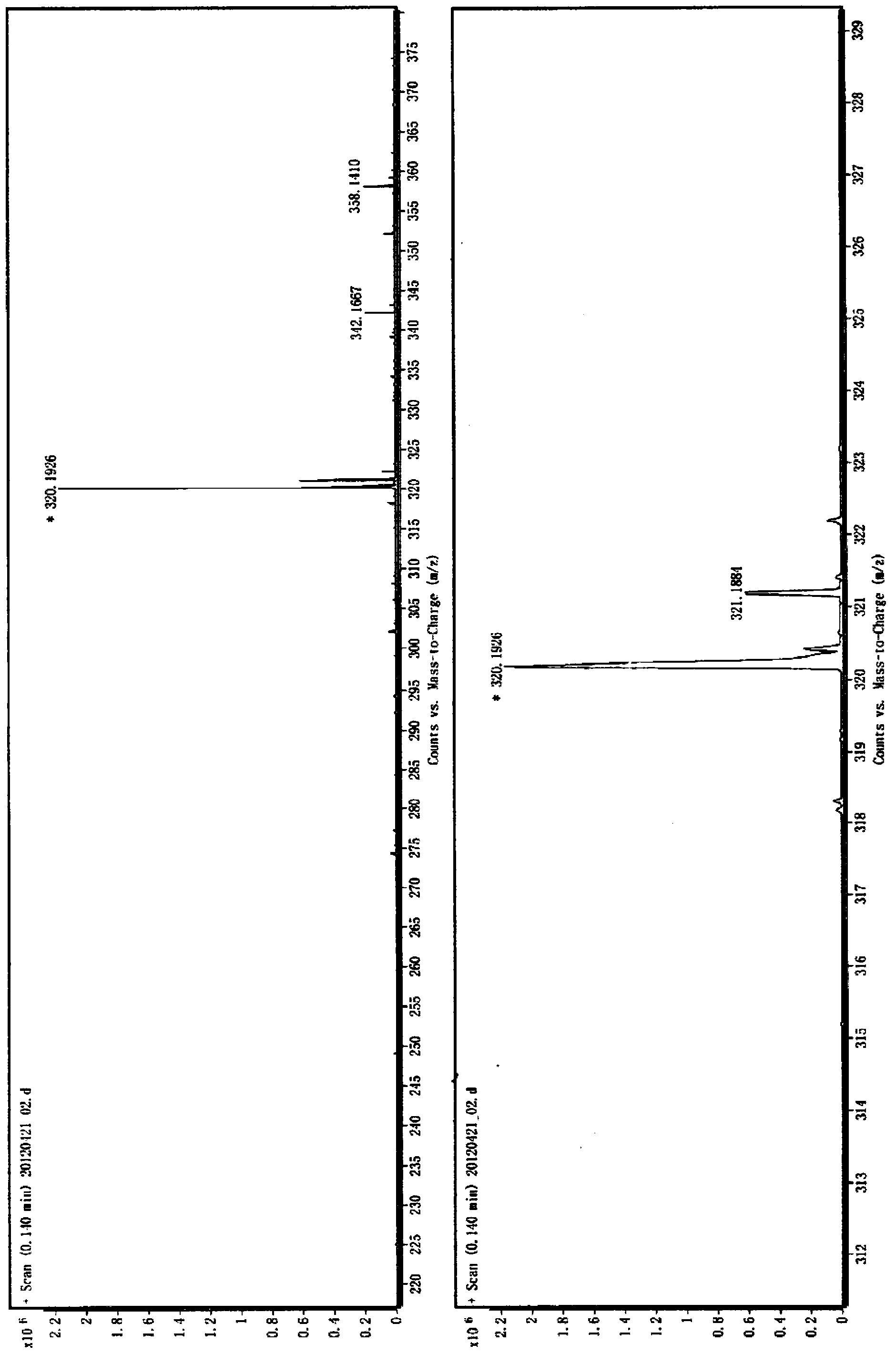

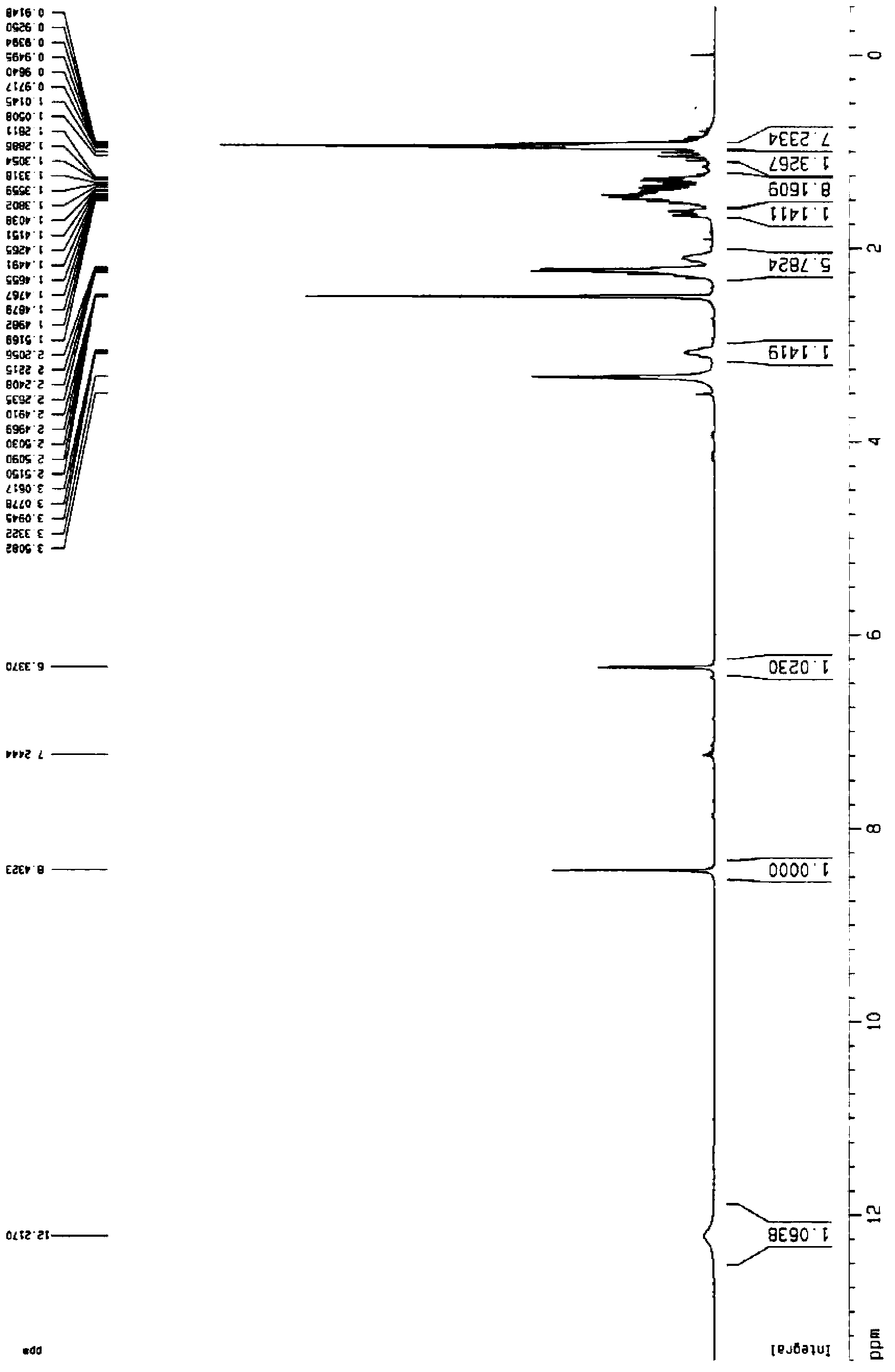

[0040] The method for detecting the content of coronatin COR by HPLC is as follows:

[0041] The purified sample was dried and dissolved in chromatographic grade methanol, and then detected by HPLC.

[0042] The HPLC conditions in this example are as follows: the chromatographic column is a 150×4.60mm C8 chromatographic column of Kromasil 5 μm 100A, the mobile phase is 80% methanol solution; the detection wavelength is 208nm, the flow rate is 2mL / min, the injection volume is 20 μL, the standard The retention time corresponding to the peak position of the product is 10min.

[0043] 1. Fermentation

[0044] Pseudomonas syringae pathogenic variety MW123 of soybean with th...

Embodiment 2、01

[0060] Embodiment 2, the preparation of 0.1% coronatin aqueous solution

[0061] 1. Selection and ratio of original drug and auxiliary agent

[0062] 0.11 parts by mass of coronatine with a purity of 95% prepared in Example 1 (that is, about 0.1 parts by mass of coronatine);

[0063] Methanol (used as solvent) 5 mass parts;

[0064] Surfactant: 5 parts by mass;

[0065] Preservative: 1 part by mass of Kason;

[0066] Antifreeze: 10 parts by mass of ethylene glycol;

[0067] Defoamer: TSA 775 0.1 parts by mass;

[0068] The remainder is water;

[0069] The total mass of all the above components is 100 parts by mass.

[0070] Two, the preparation of 0.1% coronatin aqueous solution

[0071] Dissolve coronatine with methanol and part of water to obtain coronatin mother liquor; add remaining water to the stirring tank, then add coronatin mother liquor, stir at 2000rpm for 30 minutes, then add antifreeze, surfactant and preservative in turn And antifoaming agent, contin...

Embodiment 3

[0074] Embodiment 3, the preparation of 0.003% coronatin aqueous solution

[0075] 1. Selection and ratio of original drug and auxiliary agent

[0076] 0.0032 parts by mass of coronatine with a purity of 95% prepared in Example 1 (that is, about 0.003 parts by mass of coronatine);

[0077] Methanol (used as solvent) 1 mass part;

[0078] Surfactant: 2 parts by mass of alkyl glycoside APG1200;

[0079] Preservative: 0.5 parts by mass of sodium benzoate;

[0080] Antifreeze: 5 parts by mass of ethylene glycol;

[0081] Defoamer: TSA 775 0.5 parts by mass;

[0082] The remainder is water;

[0083] The total mass of all the above components is 100 parts by mass.

[0084] Two, the preparation of 0.003% coronatin aqueous solution

[0085] Dissolve coronatine with methanol and part of water to obtain coronatin mother liquor; add remaining water to the stirring tank, then add coronatin mother liquor, stir at 3000rpm for 20 minutes, then add antifreeze, surfactant and preservati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com