Hot-blast furnace pipeline spray paint and application method thereof

A technology for spraying paint and hot blast stove, which is applied in the field of refractory castables, can solve the problems of hot blast pipe formwork, casting construction difficulties, practicability and thermal shock resistance need to be improved, and blast furnace production operation environment is deteriorated, etc. The effect of good shock resistance, promotion of coagulation and hardening, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

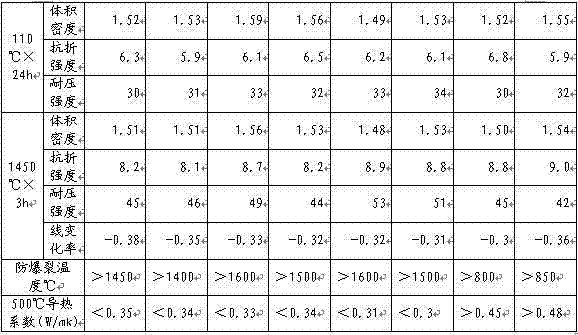

[0112] Use the ingredients of formula 1, add water and stir evenly for 8 minutes, then spray and apply, and dry and harden naturally within 25 minutes; natural curing for 20 hours. The method can be sprayed quickly without needing formwork, has good acid resistance, good heat preservation effect and low cost. The specific parameters are shown in Table 1.

Embodiment 2

[0114] Use the ingredients of formula 2, add water and stir evenly for 12 minutes, then spray and apply, and dry and harden naturally within 40 minutes; natural curing for 28 hours.

Embodiment 3

[0116] Use formula three ingredients, add water and stir evenly for 10 minutes, then apply and apply, and dry and harden naturally within 30 minutes; natural curing for 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com