Supported rubber anti-aging agent, as well as preparation method and application thereof

A rubber anti-aging agent, load-type technology, applied in the synthesis of rubber additives and rubber anti-aging fields, can solve the problems of environmental pollution, single function, low efficiency, etc., achieve large specific surface area, reduce pollution, reduce fire and explosion hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

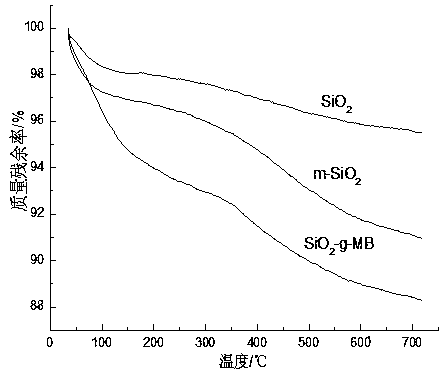

[0037] 20g of precipitated silica (SiO 2 ) was dispersed in 300ml of ethanol, 4g of γ-chloropropyltrimethoxysilane was added, and the mixture was stirred and reacted at 60°C for 10 hours. Then 2.8 g of rubber anti-aging agent 2-mercaptobenzimidazole (MB) was added, and stirred and reacted for 12 hours under nitrogen protection and 80°C. The product was separated by centrifugation and washed with ethanol, and dried in a vacuum oven to constant weight to obtain the loaded antioxidant SiO 2 -g -MB. attached figure 1 It shows that the MB grafting rate of the antioxidant is 3.0%.

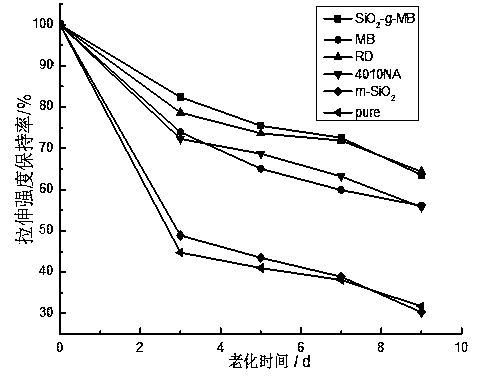

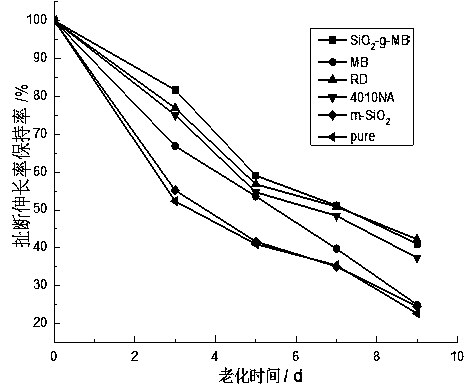

[0038] with SiO 2 - The basic formula of the styrene-butadiene rubber / silica composite material prepared by g-MB is shown in Table 1, and the unit of the dosage of each component is phr. attached figure 2 and 3 It is the change of the tensile strength and elongation at break retention rate of several vulcanizates aged at 100°C for different days. It can be seen that the SiO 2 -g-MB's SBR vulcan...

Embodiment 2

[0047] Disperse 100 g of halloysite nanotubes (HNTs) into 70 ml of acetone, add 15 g of γ-aminopropyltriethoxysilane, and react at 45° C. for 18 hours. Then add 8g of rubber anti-aging agent 2-mercaptobenzimidazole (MB), stir and react under nitrogen protection at 50°C for 20 hours, the product is centrifuged and washed with acetone, and dried in a vacuum oven to constant weight to obtain the final product HNTs-g -MB.

[0048] Raman spectrum showed that the synthesized product was the target product; thermogravimetric analysis showed that the mass fraction of MB contained in HNTs-g-MB was 3.18%.

[0049] The basic formulation of the natural rubber / halloysite composite material prepared with HNTs-g-MB is shown in Table 3, and the unit of the dosage of each component is phr. Table 4 shows the retention rate of tensile strength and elongation at break of the vulcanizate after aging at 100°C for different days. It can be seen that the thermal oxygen antiaging effect of HNTs-g-MB...

Embodiment 3

[0057] 10 grams of fumed silica (SiO 2 ) was dispersed in 200 ml of ethanol, 4 g of mercaptopropyltrimethoxysilane was added, stirred at 80°C for 12 hours, and then 50 ml of ethanol solution containing 3.2 g of 2-mercaptobenzimidazole (MB) was added dropwise at 50°C And 0.2 mole of hydrogen peroxide, the dropwise addition process is completed within 1 hour, after the dropwise addition is completed, keep the temperature and react for another 6 hours, the product is centrifugally washed with absolute ethanol, put into a vacuum oven and dry to constant weight to obtain the final product, namely Loaded multifunctional rubber additive SiO 2 -s -MB.

[0058] Product SiO 2 -S-MB prepared styrene-butadiene rubber / silica (SBR / SiO 2 ) The basic formula of the composite material is shown in Table 5, and the unit of the dosage of each component is phr. Table 6 is the vulcanization characteristic parameters of each sample. It can be seen from Table 6 that the loaded multifunctional ru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com