Low-water-absorptivity heat-conducting wear-resistant polymer alloy, and preparation method and application thereof

A polymer, low water absorption technology, applied in the field of polymer alloy materials, can solve the problems of high friction coefficient between rubber and shaft metal, low dimensional accuracy of polyurethane molding, poor dimensional stability, etc., and achieve high dimensional stability, weight reduction and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

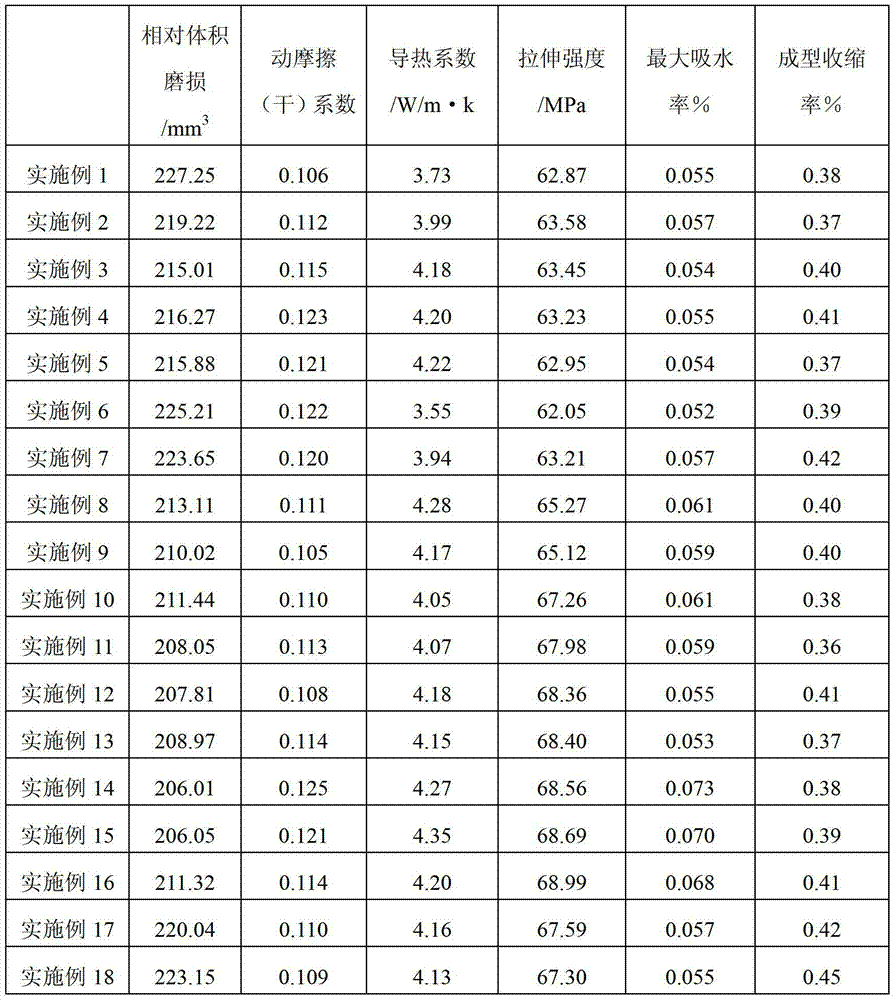

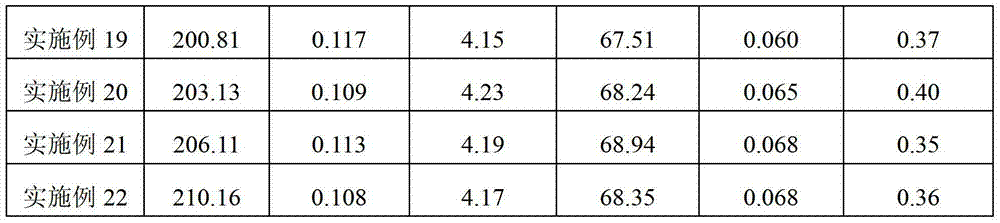

Examples

Embodiment 1

[0038] Example 1: Preparation of low water absorption, thermal conductivity and wear-resistant polymer alloy

[0039] (1) Surface treatment of graphite powder and carbon fiber: use plasma activation instrument (model is plasma cleaning experimental equipment EPT-02, produced by Suzhou Aopus Plasma Technology Co., Ltd.) to irradiate and activate graphite powder (high thermal conductivity flake shape, Shanghai Humai Composite Material Co., Ltd.) and carbon fiber (wd-3 / / 200, Dongguan Carbon Cable Composite Material Co., Ltd.), clean the surface and activate its surface sites at the same time.

[0040] Then use acetone-dispersed silane coupling agent (KH-550, produced by Beijing Shenda Fine Chemical Co., Ltd.) to dry treat carbon fiber and graphite powder for 1 to 3 hours. The operation is as follows: add 350mL toluene, 50g graphite powder or carbon fiber , 0.5g of silane coupling agent, pass into N 2 , at N 2 The temperature was raised to 85°C under airflow and the reaction was...

Embodiment 2

[0043] Example 2: Preparation of low water absorption, thermal conductivity and wear-resistant polymer alloy

[0044] (1) The treatment of graphite powder and carbon fiber, and the drying of PP, PA66, and PP-g-MA are the same as in Example 1.

[0045] (2) Mix 45g of PP with a melt index of 2g / min, 45g of PA66 with a melt index of 40g / min and 10g of PP-g-MA evenly, and melt blend (180°C) in a twin-screw granulator to obtain a total Mixture: Take 70g of the above-mentioned blend, add 10g of graphite powder, 20g of carbon fiber and mix evenly, melt and blend in a twin-screw extruder, extrude and granulate. The temperature of each section of the extruder is 170°C, 185°C, 190°C, 200°C, 220°C, 225°C, 250°C respectively. A low water absorption, thermal conductivity and wear-resistant polymer alloy is obtained.

Embodiment 3

[0046]Example 3: Preparation of low water absorption, thermal conductivity and wear-resistant polymer alloy

[0047] (1) The treatment of graphite powder and carbon fiber, and the drying of PP, PA66, and PP-g-MA are the same as in Example 1.

[0048] (2) Mix 45g of PP with a melt index of 2g / min, 45g of PA66 with a melt index of 40g / min and 10g of PP-g-MA evenly, and melt blend (180°C) in a twin-screw granulator to obtain a total Mixture: Take 60g of the above-mentioned blend, add 10g of graphite powder, 30g of carbon fiber and mix evenly, melt and blend in a twin-screw extruder, extrude and granulate. The temperature of each section of the extruder is 170°C, 185°C, 190°C, 200°C, 220°C, 225°C, 250°C respectively. A low water absorption, thermal conductivity and wear-resistant polymer alloy is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com