A kind of anti-swelling agent for acidification and preparation method thereof

A technology of anti-swelling agent and catalyst, which is applied in the field of clay anti-swelling agent for acidification and its preparation, can solve problems such as uneven compatibility, lack of corrosion inhibition ability, and polluted formation, and achieve improved chemical stability and good Corrosion inhibition effect, high-efficiency anti-expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

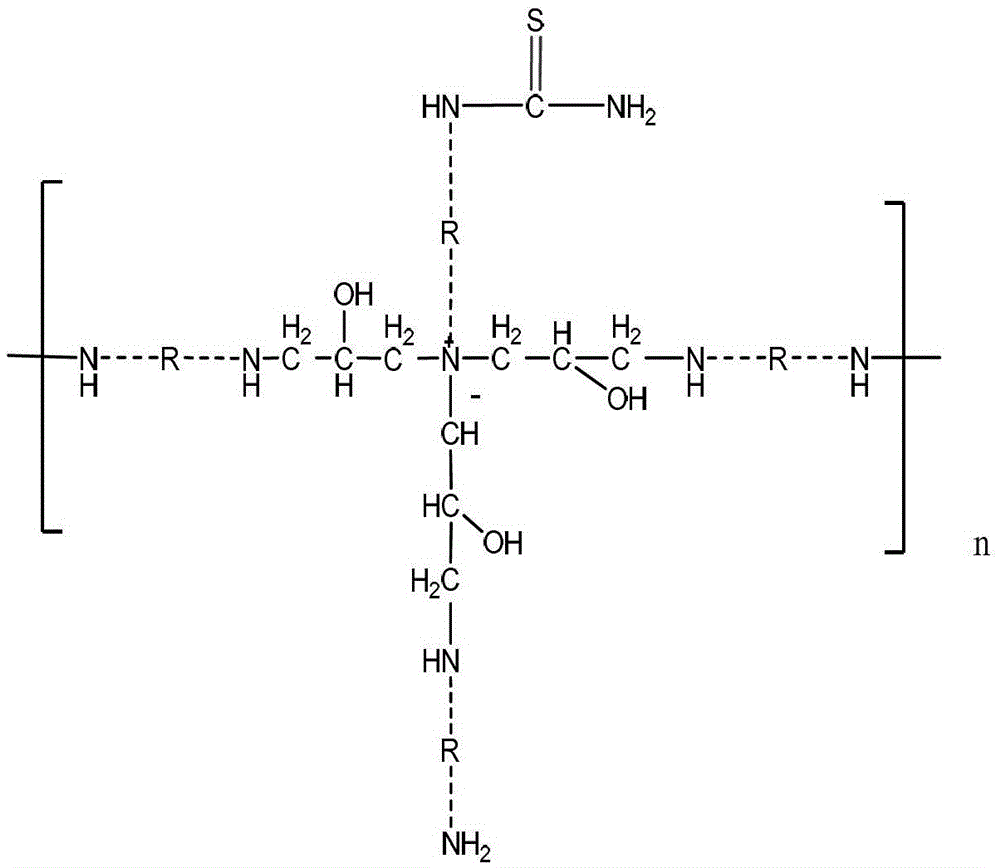

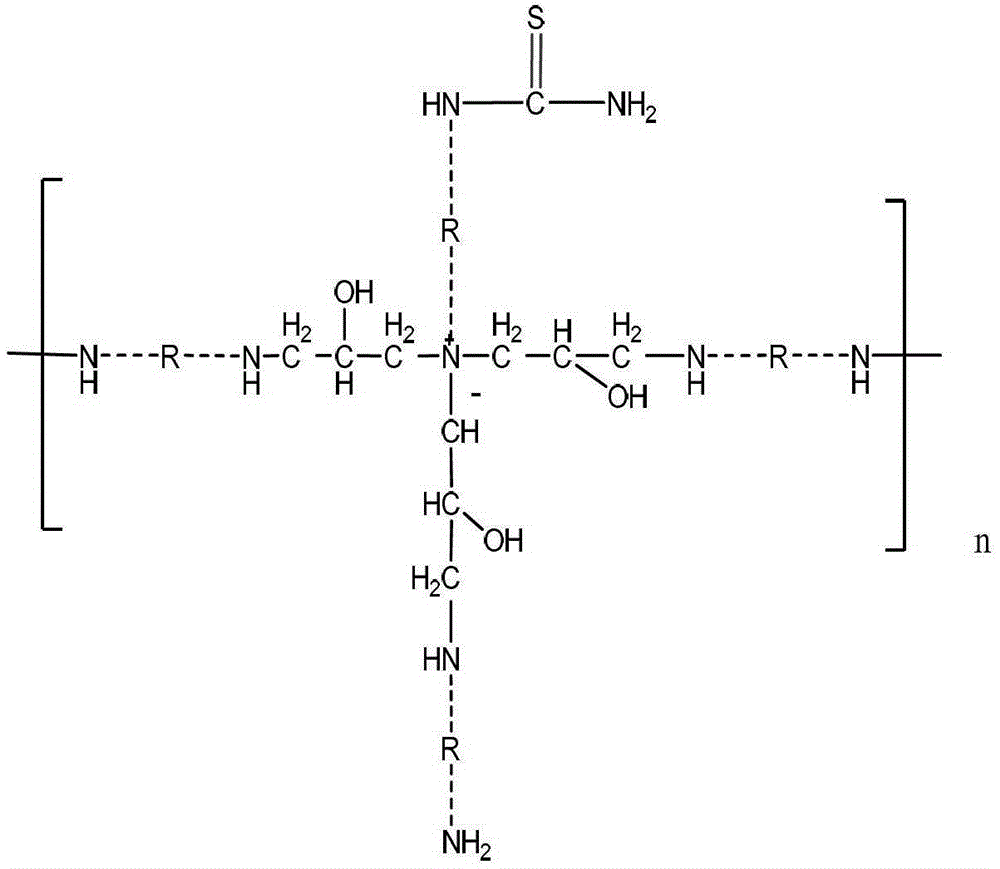

[0037] Diethylenetriamine and epichlorohydrin are fed in a molar ratio of 1:3, and at the same time, 5% solvent water and 3% catalyst sodium sulfite are added by the total weight of diethylenetriamine and epichlorohydrin, and the temperature is raised to 80°C with stirring, and reflux Stop the reaction after 5 hours to obtain the polyquaternium intermediate, then react thiourea with the polyquaternium intermediate at a molar ratio of 1:1, the reaction temperature is 30°C, and the reaction time is 2 hours to obtain the thiourea-based polyquaternium Salt products. After measurement, the viscosity-average molecular weight of the product is 4200, the anti-swelling rate is 85.6%, and the corrosion inhibition rate is 59%.

Embodiment 2

[0039] Feed triethylenetetramine and epichlorohydrin in a molar ratio of 1:3, add triethylenetetramine and epichlorohydrin total weight 8% solvent methanol and 3% catalyst sodium bisulfite at the same time, stir and heat up to 10 ℃, stop the reaction after reflux for 5 hours to obtain the polyquaternium salt intermediate, then react thiourea with the polyquaternium salt intermediate in a molar ratio of 0.8:1, the reaction temperature is 30°C, and the reaction time is 3.5 hours to obtain the thiourea group Polyquaternium products. After measurement, the viscosity-average molecular weight of the product is 3000, the anti-swelling rate is 80.7%, and the corrosion inhibition rate is 51%.

Embodiment 3

[0041] Feed tetraethylenepentamine and epichlorohydrin in a molar ratio of 1:3, add solvent ethanol with 8% of the total weight of tetraethylenepentamine and epichlorohydrin and 5% catalyst potassium sulfite at the same time, stir and heat up to 100°C , stop the reaction after reflux for 3 hours to obtain the polyquaternium salt intermediate, then react thiourea with the polyquaternium salt intermediate in a molar ratio of 1:1, the reaction temperature is 60 ° C, and the reaction time is 1 hour to obtain the thiourea-based poly Quaternary ammonium products. After measurement, the viscosity-average molecular weight of the product is 4500, the anti-swelling rate=89.1%, and the corrosion inhibition rate is 66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com