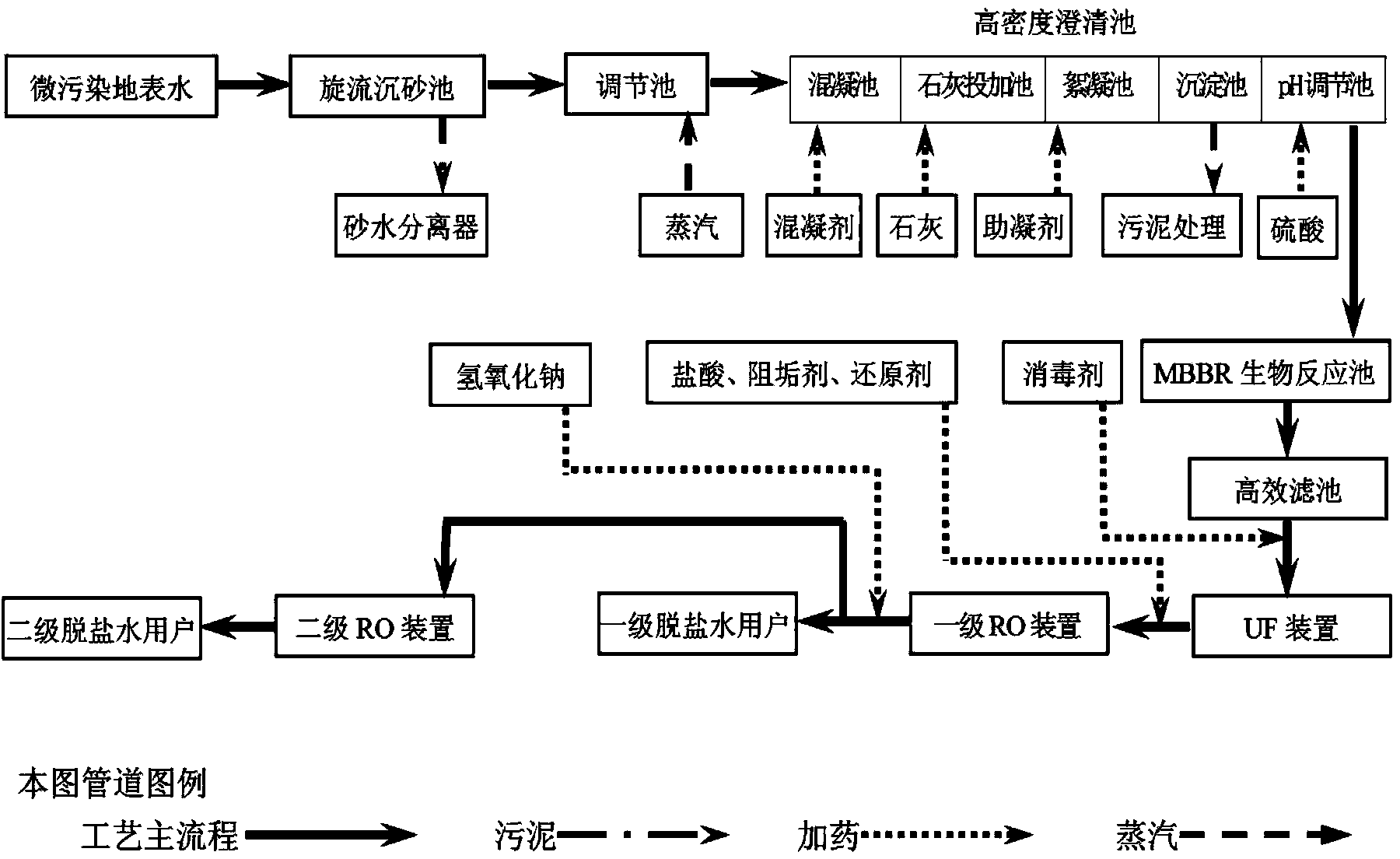

Process for preparing desalted water for iron and steel plants with slightly polluted surface water as water source

A technology for surface water and micro-pollution, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Reducing the service life of membranes and other issues, achieving the effect of obvious energy saving and emission reduction, reducing the consumption of new water in production, and improving the stability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Slightly polluted surface water source water quality: BOD 5 18mg / L, COD Cr45mg / L, NH 3 -N is 9mg / L, SS is 215mg / L, the total hardness (as CaCO 3 Calculated) is 450mg / L, the conductivity is 1250μS / cm, and the water temperature is 10℃. After the water is taken from the river, it enters the cyclone grit chamber, and the hydraulic retention time is 60s. The effluent from the cyclone grit chamber enters the regulating pond by gravity flow, and the steam in the regulating pond is heated to a water temperature of 25°C, and the hydraulic retention time of the regulating pond is 2 hours. The effluent from the regulating tank is pressurized and lifted into the high-density clarifier tank for coagulation and sedimentation treatment. The high-density clarifier includes five parts: coagulation tank, lime dosing tank, flocculation tank, sedimentation tank and pH adjustment tank. The parameters of each tank are as follows: the hydraulic retention time of the coagulation tank is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com