Preparation method of dianthus chinensis magnolol

A technology of magnolol and dianthus, which is applied in the field of separation and preparation of dianthus magnolol, can solve the problems such as the preparation method of high-content dianthus magnolol, and achieve the effects of short preparation cycle, serious pollution and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

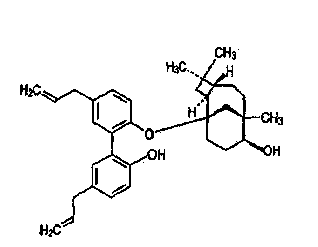

Image

Examples

Embodiment 1

[0021] Get the stem bark of Magnolia officinalis, after crushing, weigh 1kg, add 5 times of 80% ethanol solution, the extraction voltage is 140V, the extraction time is 90s, carry out flash extraction, filter to obtain the extract, the extract is passed through a molecular weight cut-off of 3000 ultrafiltration membrane ultrafiltration and nanofiltration membrane concentration with a molecular weight cut-off of 500, the operating pressure is 0.8MPa, the membrane concentrate is concentrated and dried under reduced pressure to obtain a crude extract; high-speed countercurrent chromatography is used to separate and purify Dianthus in the crude extract Magnolol, with a volume ratio of 5:4:6:2 petroleum ether-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a high-speed countercurrent chromatographic column as the stationary phase, the host is rotated, and pumped into the lower phase to make The mobile phase, the crude extract dissolved in t...

Embodiment 2

[0023] Get the stem bark of Magnolia officinalis, after pulverization, weigh 1kg, add 12 times of 80% ethanol solution, the extraction voltage is 140V, the extraction time is 80s, carry out flash extraction, filter to obtain the extract, the extract is passed through a molecular weight cut-off of 1000 ultrafiltration membrane ultrafiltration and nanofiltration membrane concentration with a molecular weight cut-off of 500, the operating pressure is 1.8MPa, the membrane concentrate is concentrated and dried under reduced pressure to obtain a crude extract; high-speed countercurrent chromatography is used to separate and purify Dianthus in the crude extract Magnolol, with a volume ratio of 7:3:4:3 petroleum ether-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a high-speed countercurrent chromatographic column as the stationary phase, the host is rotated, and pumped into the lower phase to make The mobile phase, the crude extract dissolve...

Embodiment 3

[0025] Get the stem bark of Magnolia officinalis, after pulverization, weigh 2kg, add 10 times of 80% ethanol solution, the extraction voltage is 140V, the extraction time is 90s, carry out flash extraction, filter to obtain the extract, the extract is passed through a molecular weight cut-off of 1000 ultrafiltration membrane ultrafiltration and nanofiltration membrane concentration with a molecular weight cut-off of 300, the operating pressure is 2.0MPa, the membrane concentrate is concentrated and dried under reduced pressure to obtain a crude extract; high-speed countercurrent chromatography is used to separate and purify Dianthus in the crude extract Magnolol, with a volume ratio of 6:4:6:3 petroleum ether-ethyl acetate-methanol-water as a two-phase solvent system, the upper phase is filled with a high-speed countercurrent chromatographic column as the stationary phase, the host is rotated, and pumped into the lower phase to make The mobile phase, the crude extract dissolve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com