Hydrothermal preparation method of V10O24.12H2O

A V10O24·12H2O, hydrothermal technology, applied in vanadium oxide and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

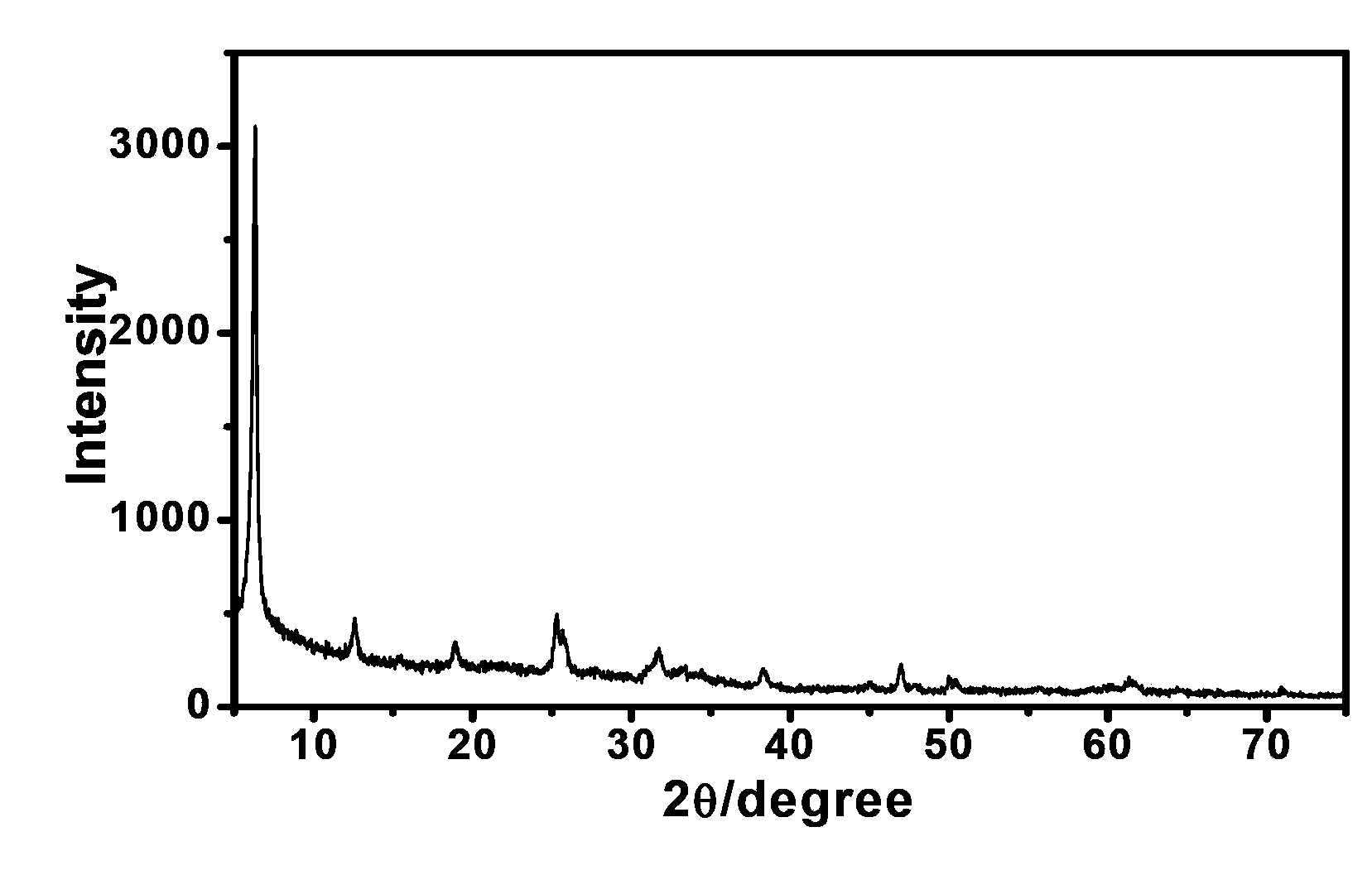

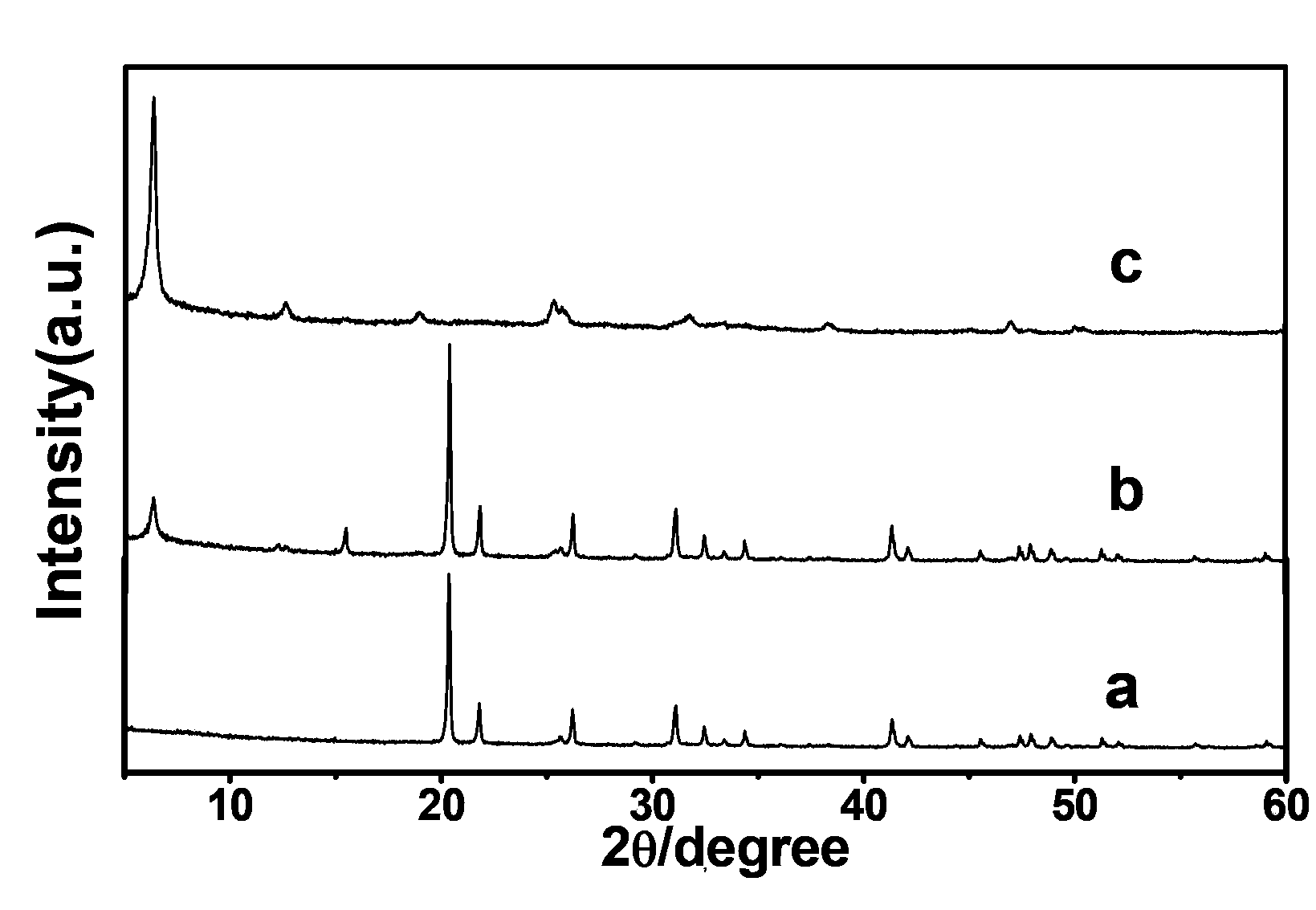

Image

Examples

Embodiment 1

[0021] Take 3ml of acetic acid solution with a concentration of 36%, and prepare a mixed solution with 9ml of deionized water; put the prepared solution into a 30ml hydrothermal reaction kettle, add 0.114gV 2 o 5 Powder, fully stirred with a magnetic stirrer for 30 minutes, and mixed; put the reaction kettle in an oven, reacted at 180°C for 24 hours, and cooled naturally at room temperature; soaked and washed the reaction product in deionized water repeatedly, settled for 3 times, and vacuum filtered , and dried at 105°C, the target product V can be obtained 10 o 24 12H 2 O powder.

Embodiment 2

[0023] Take 3ml of acetic acid solution with a concentration of 36%, and prepare a mixed solution with 9ml of deionized water; put the prepared solution into a 30ml hydrothermal reaction kettle, add 0.085gV 2 o 5 Powder, fully stirred with a magnetic stirrer for 30 minutes, and mixed; put the reaction kettle in an oven, reacted for 48 hours at 150°C, and cooled naturally at room temperature; soaked and washed the reaction product in deionized water repeatedly, settled for 3 times, and vacuum filtered , and dried at 105°C, the target product V can be obtained 10 o 24 12H 2 O powder.

Embodiment 3

[0025] Take 3ml of acetic acid solution with a concentration of 36%, and mix it with 9ml of deionized water to make a mixed solution; put the prepared solution into a 30ml hydrothermal reaction kettle, add 0.187gV 2 o 5 Powder, fully stirred with a magnetic stirrer for 30 minutes, and mixed; put the reaction kettle in an oven, reacted at 240 ° C for 24 hours, and cooled naturally at room temperature; repeatedly soaked and washed the reaction product in deionized water, settled for 3 times, and vacuum filtered , and dried at 105°C, the target product V can be obtained 10 o 24 12H 2 O powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com