Method for efficiently recycling ferro-aluminium from bauxite tailings and synchronously preparing high siliceous residues

A bauxite and aluminum recovery technology, applied in the direction of improving process efficiency, can solve the problems of no thermal activation, low recovery rate of leachables, large amount of residue, etc., and achieve the effect of wide application range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

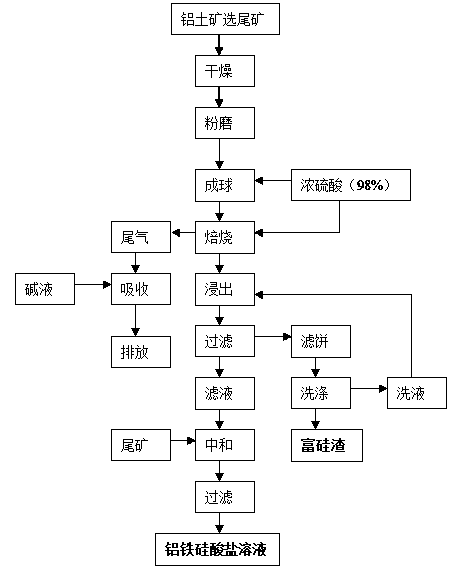

[0035] Implementation mode one: if figure 1 As shown, the method for the high-efficiency recovery of aluminum and iron from the bauxite beneficiation tailings of the present embodiment to simultaneously prepare high silicic acid slag is:

[0036] (1) Dry and grind the bauxite tailings until the 100-mesh sieve balance is less than 5%, add concentrated sulfuric acid and mix evenly, and make according to the mass ratio of tailings powder and concentrated sulfuric acid 1:1.2 The sphere is then heated to 250°C for roasting. During the roasting process, concentrated sulfuric acid is continuously added to keep the concentrated sulfuric acid liquid from flowing out of the bauxite tailings sphere. The total amount of sulfuric acid added is 1.2 times the theoretical acid consumption of aluminum and iron oxides in bauxite tailings, and roasted under the above conditions for 0.5h; bauxite tailings are solid waste after bauxite wet beneficiation , the main chemical composition Al in the b...

Embodiment approach 2

[0039] Implementation mode two: if figure 1 As shown, the method for the high-efficiency recovery of aluminum and iron from the bauxite beneficiation tailings of the present embodiment to simultaneously prepare high silicic acid slag is:

[0040] (1) Dry and grind the bauxite tailings until the 100-mesh sieve balance is less than 5%, add concentrated sulfuric acid to mix evenly and make a sphere, then heat to 300°C and roast. Concentrated sulfuric acid is continuously added during the process to shorten the acid addition time while keeping the concentrated sulfuric acid liquid from flowing out of the bauxite tailings sphere. The acid addition time is 15 minutes in total. The total amount of concentrated sulfuric acid added is The theoretical acid consumption of aluminum and iron oxides is 1 time, roasted under the above conditions for 0.8h; the main chemical composition of bauxite tailings is Al 2 o 3 , Fe 2 o 3 , SiO 2 、TiO 2 , MgO, and CaO are respectively: 38.88%, 26....

Embodiment approach 3

[0043] Implementation mode three: if figure 1 As shown, the method for the high-efficiency recovery of aluminum and iron from the bauxite beneficiation tailings of the present embodiment to simultaneously prepare high silicic acid slag is:

[0044] (1) Dry and grind the bauxite tailings until the 100-mesh sieve balance is less than 5%, add concentrated sulfuric acid to mix evenly and make a sphere, then heat to 260°C and roast. Concentrated sulfuric acid is continuously added during the process to shorten the acid addition time while keeping the concentrated sulfuric acid liquid from flowing out of the bauxite tailings sphere. The total amount of concentrated sulfuric acid added is the theoretical consumption of aluminum and iron oxides in the bauxite tailings 1.4 times the amount of acid, roasted under the above conditions for 1 hour; the tail gas produced by roasting the bauxite tailings spheres is absorbed by the lye and discharged. Main chemical composition Al in bauxite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com