Core-shell TiO2/ZnIn2S4 composite photocatalyst and preparation method and application thereof

A technology of znin2s4 and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low photocatalytic quantum efficiency, achieve high photocatalytic activity, wide visible light response range, and low cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A Visible Light Responsive Core-Shell TiO 2 / ZnIn 2 S 4 The preparation method of composite photocatalyst comprises the following steps:

[0029] (1) 20mg TiO 2 Ultrasonic dispersion in 30ml ethanol solvent for 10 minutes, the frequency of ultrasonic treatment is 40KHz, and the power is 50W;

[0030] (2) 2mmol zinc chloride and 4mmol indium nitrate are stirred and dissolved in 30ml ethanol solvent;

[0031] (3) Mix the suspension prepared in step (1) with the solution prepared in step (2), add 12 mmol thioacetamide and stir at a speed of 500 r / min for 20 minutes;

[0032] (4) Transfer the reaction system of step (3) to an autoclave, and react at 160° C. for 6 hours;

[0033] (5) Pour the product of step (4) into a vacuum filtration device for suction filtration, wash with deionized water, dry at 60°C for 6 hours, and obtain core-shell TiO after grinding 2 / ZnIn 2 S 4 composite photocatalyst.

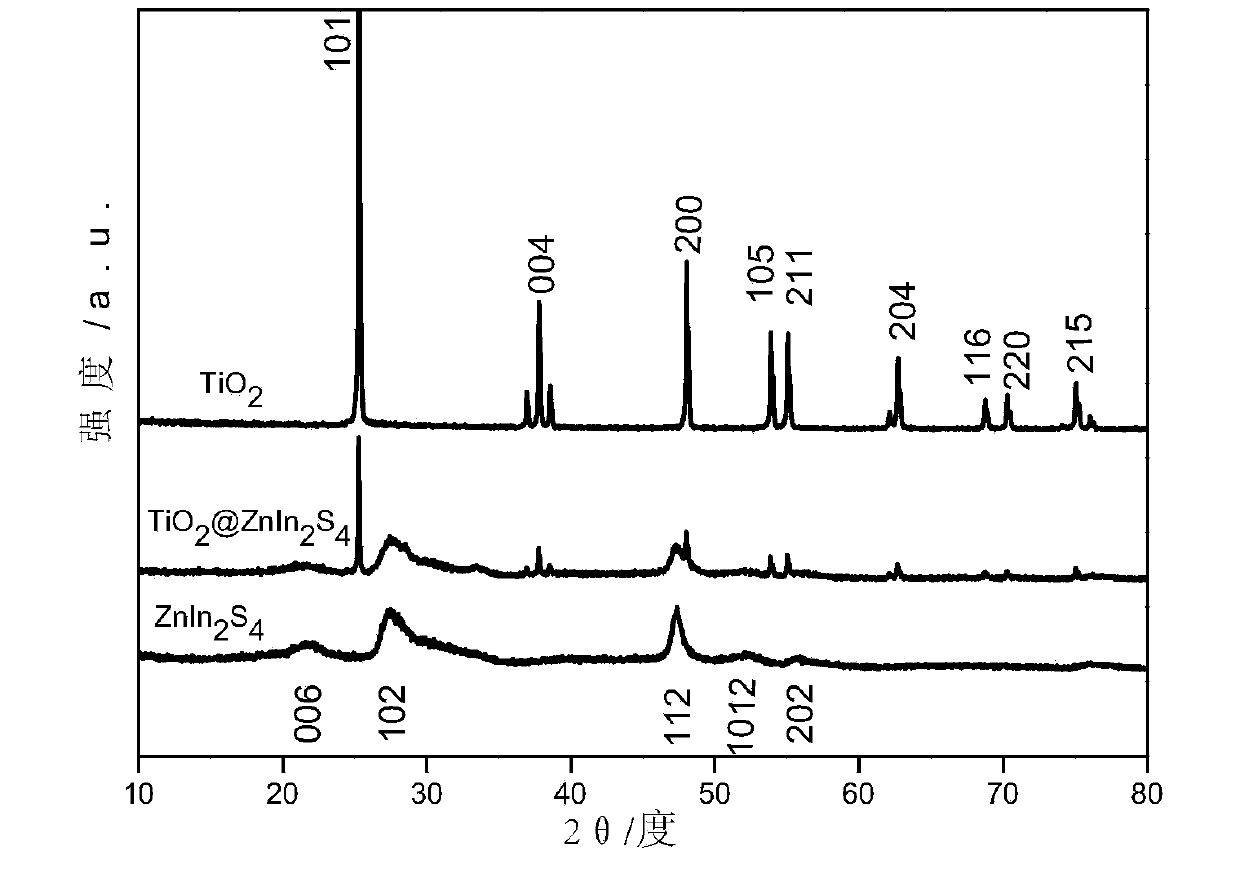

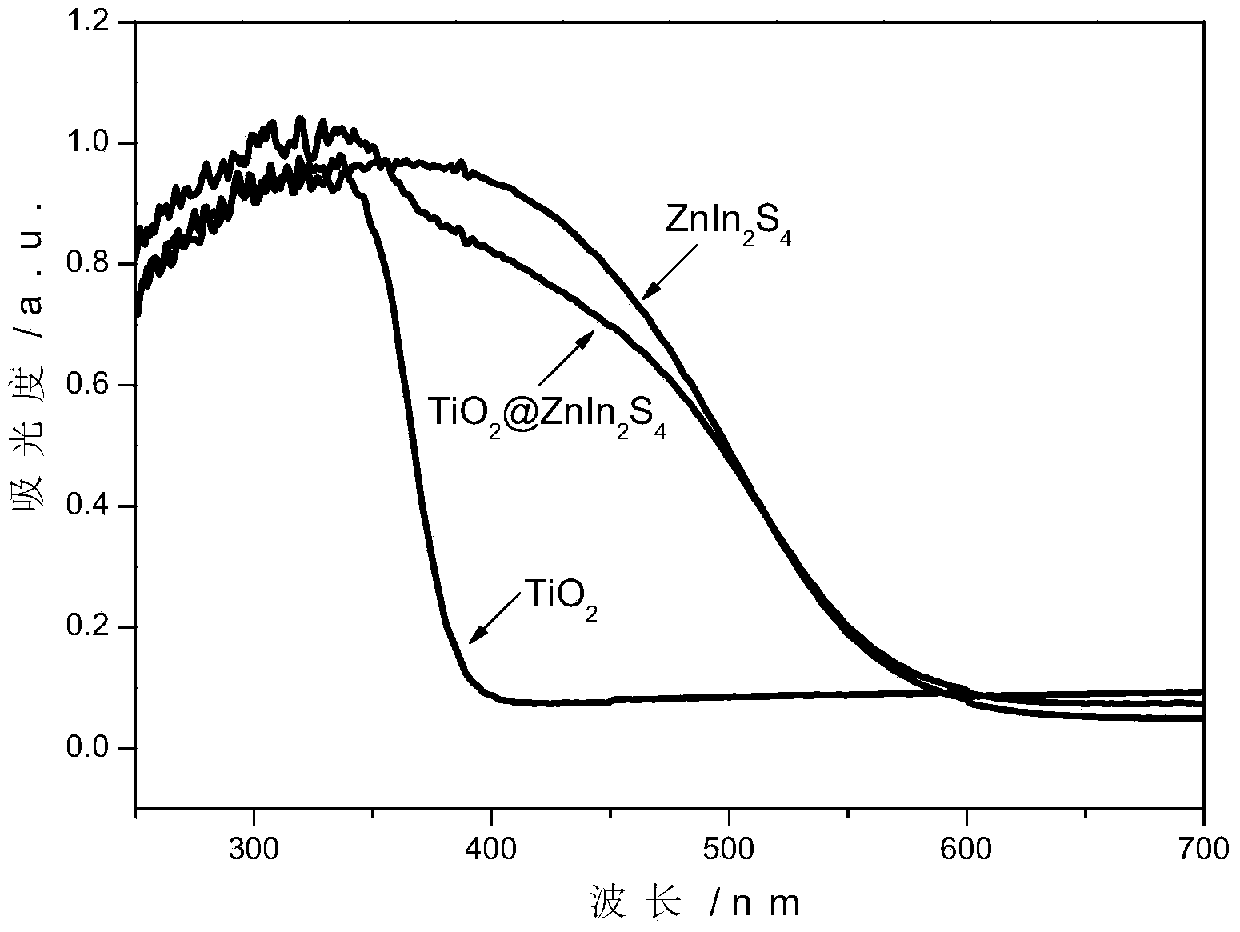

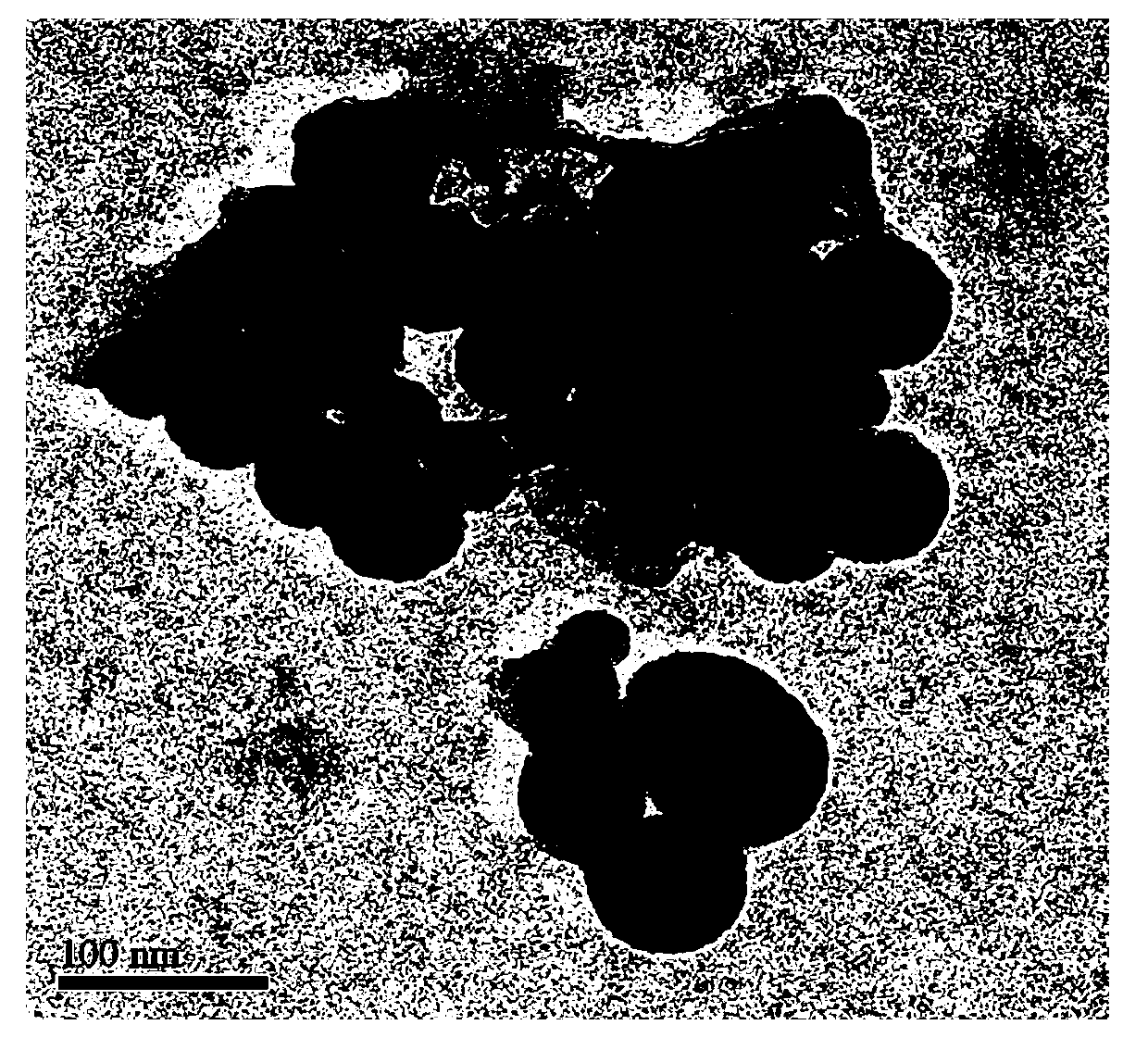

[0034] figure 1 It is TiO in embodiment 1 2 and prepared ZnIn 2 S...

Embodiment 2

[0036] A Visible Light Responsive Core-Shell TiO 2 / ZnIn 2 S 4 The preparation method of composite photocatalyst comprises the following steps:

[0037] (1) 40mg TiO 2 Ultrasonic dispersion in 30ml ethanol solvent for 12 minutes; the frequency of ultrasonic treatment is 40KHz, and the power is 50W;

[0038] (2) 2mmol zinc chloride and 4mmol indium nitrate are stirred and dissolved in 30ml ethanol solvent;

[0039] (3) Mix the suspension prepared in step (1) with the solution prepared in step (2), add 12 mmol thioacetamide and stir at a speed of 500 r / min for 30 minutes;

[0040] (4) Transfer the reaction system of step (3) to an autoclave, and react at 180°C for 8 hours;

[0041] (5) Pour the product of step (4) into a vacuum filtration device for suction filtration, wash with deionized water, dry at 70°C for 5 hours, and grind to obtain core-shell TiO 2 / ZnIn 2 S 4 composite photocatalyst.

[0042] TiO in this embodiment 2 / ZnIn 2 S 4 X-ray diffraction pattern, vi...

Embodiment 3

[0044] A Visible Light Responsive Core-Shell TiO 2 / ZnIn 2 S 4 The preparation method of composite photocatalyst comprises the following steps:

[0045] (1) 80mg TiO 2 Ultrasonic dispersion in 30ml ethanol solvent for 15 minutes; the frequency of ultrasonic treatment is 45KHz, and the power is 75W;

[0046] (2) 2mmol zinc chloride and 4mmol indium nitrate are stirred and dissolved in 30ml ethanol solvent;

[0047] (3) Mix the suspension prepared in step (1) with the solution prepared in step (2), add 12 mmol thioacetamide and stir for 40 minutes at a speed of 500 r / min;

[0048] (4) Transfer the reaction system of step (3) to an autoclave, and react at 200° C. for 12 hours;

[0049] (5) Pour the product of step (4) into a vacuum filtration device for suction filtration, wash with deionized water, dry at 80°C for 4 hours, and grind to obtain core-shell TiO 2 / ZnIn 2 S 4 composite photocatalyst.

[0050] TiO in this embodiment 2 / ZnIn 2 S 4 X-ray diffraction pattern,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com