Treatment methodMethod for treating to wastewater by using membrane coagulation reactor-ozone-biological activated carbon technique

A technology of biological activity and treatment method, which is applied in the field of sewage treatment, can solve the problems that the sewage treatment plants in the park cannot meet the discharge standards, and the tail gas needs to be treated separately, so as to solve the problems of non-compliance discharge, reduce ozone consumption, and reduce pollution indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A membrane coagulation reactor ozone biological activated carbon technology for treating sewage,

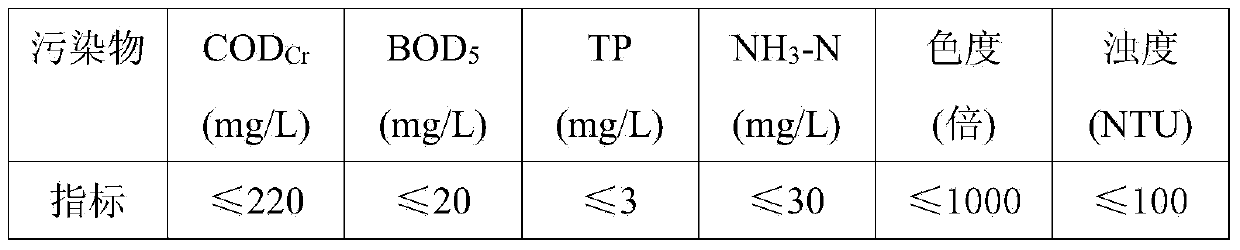

[0046] (1) Introduce the pre-treated sewage into the MCR system to make the turbidity of the produced water ≤0.5NTU; the indicators after the pre-treatment are as follows:

[0047]

[0048] Among them, the MCR system adopts submerged hollow fiber membrane or submerged flat membrane, the membrane separation pore size is 0.3μm, and the membrane flux is 60L / m 3 h;

[0049] (2) The product water of the MCR system enters the O 3 Oxidation system for oxidation; treated water in O 3 Oxidation system residence time 30min, O 3 BOD of water produced in oxidation system 5 / COD Cr ≥0.15;

[0050] (3)O 3 The water produced from the oxidation system enters the BAC system, and the treated water stays in the BAC system for 2 hours; through the synergistic effect of activated carbon adsorption and microbial degradation, the pollutants in the wastewater are completely decomposed, ...

Embodiment 2

[0055] A kind of membrane coagulation reactor ozone biological activated carbon technology is characterized in that comprising the following steps:

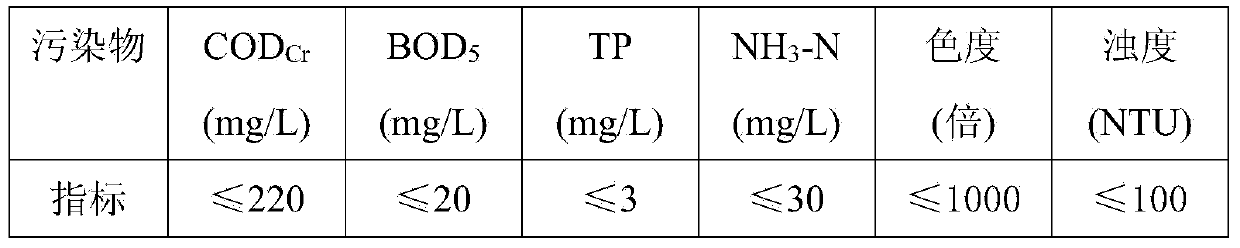

[0056] (1) Introduce the pre-treated sewage into the MCR system to make the turbidity of the produced water ≤0.5NTU; the indicators after the pre-treatment are as follows:

[0057]

[0058] Among them, the MCR system adopts submerged hollow fiber membrane or submerged flat membrane, the membrane separation pore size is 0.1μm, and the membrane flux is 50L / m 3 h;

[0059] (2) The product water of the MCR system enters the O 3 Oxidation system for oxidation; treated water in O 3 Oxidation system residence time 30min, O 3 BOD of water produced in oxidation system 5 / COD Cr ≥0.15;O 3 The ozone generator in the oxidation system uses an oxygen source, and the oxygen concentration of the oxygen source is ≥85%. MCR system membrane flux is 35L / m 3 h; the residence time in the BAC system is 1.5h.

[0060] (3)O 3 The water produ...

Embodiment 3

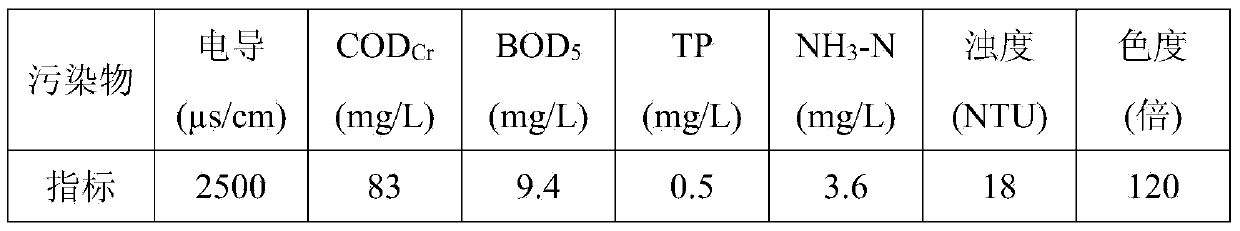

[0066] A membrane coagulation reactor (MCR)-ozone (O 3 )-Biologically activated carbon (BAC) technology park sewage treatment plant's treatment method for sewage, in which the specific indicators of pollutants are as follows (the table is the average value of long-term monitoring):

[0067]

[0068] (1) Introduce the water produced from the biochemical sedimentation tank of the above-mentioned park sewage treatment plant into the raw water tank;

[0069] (2) The water in the raw water pool passes through the raw water lifting pump and enters the MCR pool. Under the negative pressure suction of the MCR suction pump, the water in the MCR pool is intercepted by the membrane, and the MCR produced water enters the MCR produced water pool; the MCR membrane Pore size 0.04μm, membrane flux 41L / m 3 h, produced water turbidity ≤ 0.3NTU, chromaticity ≤ 100 times, COD Cr ≤70mg / L;

[0070] (3) MCR product water through O 3 Inlet pump enters O 3 The reaction tower, the ozone gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com