A kind of aluminum-doped zinc oxide target material and preparation method thereof

A technology of aluminum-doped zinc oxide and zinc oxide, which is applied in the field of photoelectric functional materials, can solve problems such as uneven mixing of raw materials and complicated preparation methods, and achieve the effects of less impurities, overcoming complicated preparation methods, and good quality targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

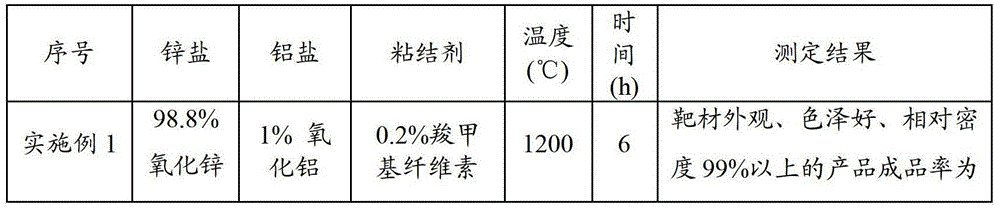

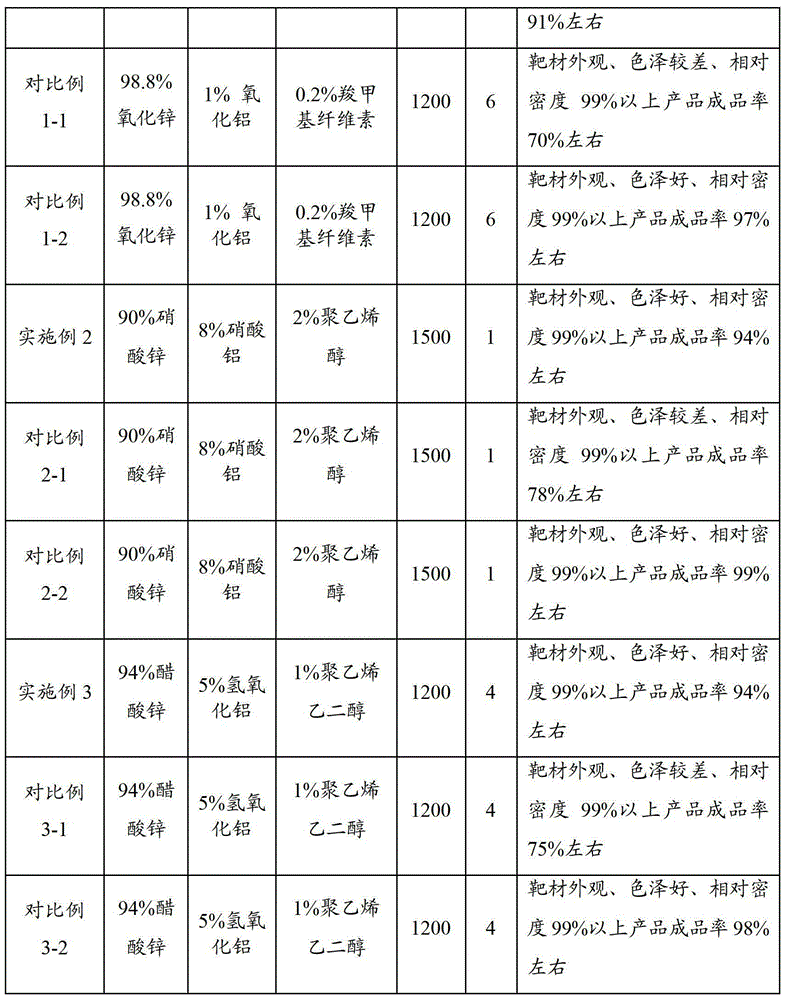

Embodiment 1

[0022] A method for preparing an AZO target, the specific steps are as follows:

[0023] Dissolve aluminum oxide and carboxymethyl cellulose in absolute ethanol, mix well to obtain a mixed solution, then add zinc oxide to the mixed solution, stir evenly, and obtain a mixed powder after drying, and cool the mixed powder under a pressure of 5Mpa The green body is obtained by isostatic pressing, and then the green body is sintered at 1200°C for 6 hours in an air atmosphere to obtain an AZO target, wherein the weight of absolute ethanol is 20 times the weight of zinc salt, the weight of aluminum oxide, The weight and the weight of carboxymethyl cellulose account for 1%, 98.8% and 0.2% of the total weight of aluminum oxide, zinc oxide and carboxymethyl cellulose respectively.

Embodiment 2

[0029] A method for preparing an AZO target, the specific steps are as follows:

[0030] Dissolve aluminum nitrate and polyvinyl alcohol in a mixed solvent formed by absolute ethanol and water at a volume ratio of 1:1, mix well to obtain a mixed solution, then add zinc nitrate to the mixed solution, stir evenly, and dry to obtain Mix the powder, cold isostatically press the mixed powder at 20Mpa to obtain a green body, and then sinter the green body at 1500°C for 1 hour in an air atmosphere to obtain an AZO target, wherein the weight of absolute ethanol and water is zinc salt 10 times the weight, the weight of aluminum nitrate, zinc nitrate and polyvinyl alcohol accounts for 8%, 90% and 2% of the total weight of aluminum nitrate, zinc nitrate and polyvinyl alcohol respectively.

Embodiment 3

[0036] A method for preparing an AZO target, the specific steps are as follows:

[0037] Dissolve aluminum hydroxide and polyethylene glycol in water, mix well to obtain a mixed solution, then add zinc acetate to the mixed solution, stir evenly, and dry to obtain a mixed powder, and cool the mixed powder under a pressure of 10Mpa The green body was obtained by compression molding, and then the green body was sintered at 1200°C for 4 hours in an air atmosphere to obtain an AZO target, wherein the weight of water was 50 times the weight of zinc salt, the weight of aluminum hydroxide, the weight of zinc acetate and the weight of poly The weight of ethylene glycol accounts for 5%, 94% and 1% of the sum of the weight of aluminum hydroxide, zinc acetate and polyethylene glycol respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com