Waterproof staining-resisting nano composite coating as well as preparation and application methods thereof

A nano-composite and coating technology, applied in the field of nano-materials, can solve the problems that do not involve the coating's anti-fouling ability, and achieve the effects of large-scale production, reduced water absorption, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

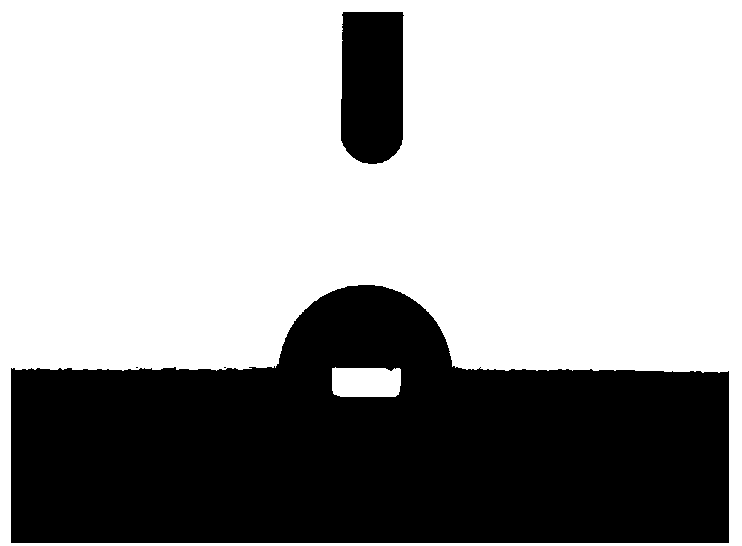

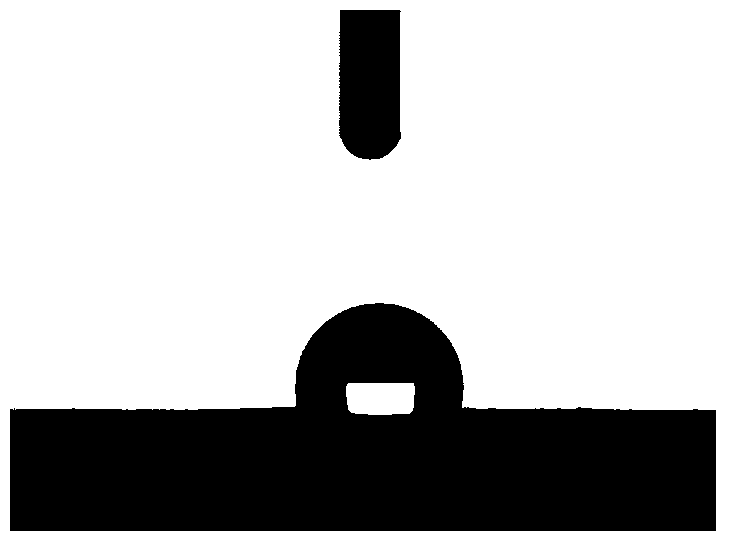

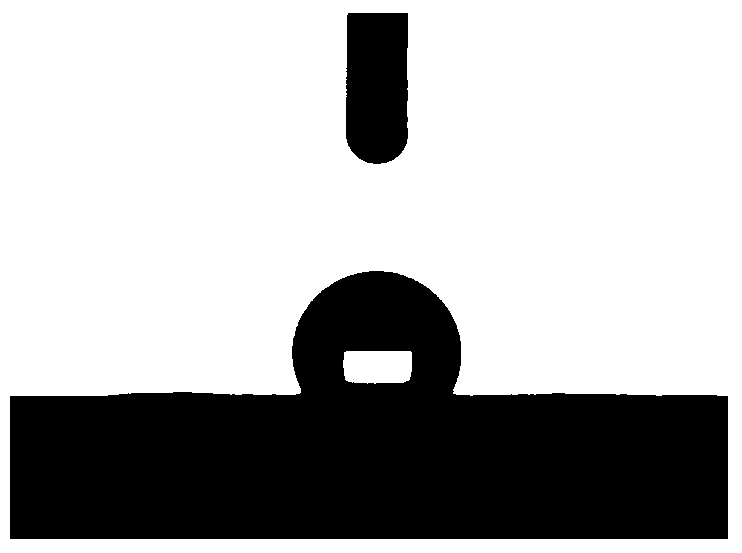

Image

Examples

Embodiment 1

[0031] The present embodiment prepares the waterproof and stain-resistant nano-composite coating according to the following proportions, in terms of weight fraction: 25 parts of isooctyltriethoxysilane, 0.1 part of rutile nano-titanium dioxide particles, 2.5 parts of Span60, 2.5 parts of Tween80, deionized 69.9 parts of water.

[0032] The preparation process of this embodiment is as follows:

[0033] Add 2.5 parts by weight of Span60 and 2.5 parts by weight of Tween80 into 15 parts by weight of deionized water, heat to dissolve, and fully stir and mix evenly at a stirring speed of 1500 r / min to obtain an emulsifier dispersion.

[0034] At a stirring speed of 1500 r / min, add 25 parts by weight of alkylisooctyltriethoxysilane into the above-mentioned emulsifier dispersion, continue stirring after the addition, and mix well to obtain a uniform dispersion of silane.

[0035] At a stirring speed of 1500r / min, add the remaining deionized water to the above-mentioned silane homogen...

Embodiment 2

[0039] In this example, a waterproof and stain-resistant nanocomposite coating was prepared according to the following proportions, in terms of weight fractions: 40 parts of isooctyltriethoxysilane, 0.2 parts of nano-silica particles, 603 parts of Span, 803 parts of Tween, and 53.8 parts of deionized water.

[0040] The preparation process of this embodiment is as follows:

[0041] Add 3 parts by weight of Span60 and 3 parts by weight of Tween80 into 18 parts by weight of deionized water, heat to dissolve, and fully stir and mix evenly at a stirring speed of 1500 r / min to prepare an emulsifier dispersion.

[0042] At a stirring speed of 1500r / min, add 40 parts by weight of alkylisooctyltriethoxysilane into the above-mentioned emulsifier dispersion, continue stirring after the addition, and mix well to obtain a uniform dispersion of silane.

[0043] At a stirring speed of 1500r / min, add the remaining deionized water to the above-mentioned silane homogeneous dispersion, and afte...

Embodiment 3

[0047] In this example, a waterproof and stain-resistant nanocomposite coating was prepared according to the following proportions, in terms of weight fractions: 50 parts of isooctyltriethoxysilane, 0.2 parts of nano-zinc oxide particles, 604 parts of Span, 804 parts of Tween, and 41.8 parts of deionized water.

[0048] The preparation process of this embodiment is as follows:

[0049] Add 4 parts by weight of Span60 and 4 parts by weight of Tween80 into 24 parts by weight of deionized water, heat to dissolve, and fully stir and mix evenly at a stirring speed of 1500 r / min to prepare an emulsifier dispersion.

[0050] At a stirring speed of 1500r / min, add 50 parts by weight of alkylisooctyltriethoxysilane into the above emulsifier dispersion, continue stirring after the addition, and mix well to obtain a uniform dispersion of silane.

[0051] At a stirring speed of 1500r / min, add the remaining deionized water to the above-mentioned silane homogeneous dispersion, and after the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com