Lithium ion secondary battery, anode material for same and preparation method of anode material

A negative electrode material and secondary battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as easy aggregation of nanomaterials, peeling of electrode materials, collapse of material structures, etc., to achieve High first cycle charge and discharge efficiency, good capacity and cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

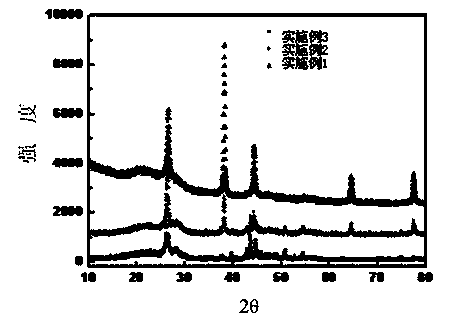

[0034] Preparation of negative electrode material: 50 parts by weight of silicon monoxide, 25 parts of pitch, 25 parts of graphite, and 10 parts of silver acetate were added, and then on a high-energy ball mill with 500 rpm high-speed ball milling for 48 hours, during ball milling Ethanol may be added as a solvent. Put the above mixture into a quartz boat, carbonize at 900°C in a high-temperature tube furnace under the protection of Ar, and ball mill and sieve the carbonized product to obtain silicon composite powder as the negative electrode material. Analysis by X-ray diffractometer (XRD), such as figure 1 As shown, there is no obvious crystallization peak of silicon in its X-ray, which proves that silicon is in an amorphous state in the negative electrode material of the present invention, and there is a diffraction peak of typical metallic silver, which proves that the silver acetate added in the present invention is reduced to metal silver. Transmission through TEM,...

Embodiment 2

[0041] Prepare the negative electrode material: 40 parts by weight of silicon monoxide, 10 parts of silicon and 25 parts of pitch, 25 parts of graphite, and 5 parts of silver acetate are added, and then 48 parts of high-speed ball milling at 400 rpm on a high-energy ball mill. Hours, ethanol can be added as a solvent during ball milling. Put the above mixture into a quartz boat, and carry out carbonization at 1000°C in a high-temperature tube furnace under the protection of Ar, and then ball mill and sieve the carbonized product to obtain silicon composite material powder as the negative electrode material. Analyzed by X-ray diffractometer, such as figure 1 As shown, there is no obvious crystallization peak of silicon in its X-ray, which proves that silicon is in an amorphous state in the negative electrode material of the present invention, and there is a diffraction peak of typical metallic silver, which proves that the silver acetate added in the present invention is re...

Embodiment 3

[0044] Prepare the negative electrode material: 50 parts by weight of silicon dioxide, 25 parts of pitch, and 25 parts of graphite are then ball milled at a high speed of 500 rpm for 48 hours on a high-energy ball mill. Ethanol can be added as a solvent during ball milling. Put the above mixture into a quartz boat, and carry out carbonization at 1000°C in a high-temperature tube furnace under the protection of Ar, and then ball mill and sieve the carbonized product to obtain silicon composite material powder as the negative electrode material. Analyzed by X-ray diffractometer, such as figure 1 As shown, there is no obvious crystallization peak of silicon in its X-ray, which proves that silicon in the negative electrode material of the present invention is in an amorphous state.

[0045] Same as Example 1, the negative electrode material of the present invention was used in the manufacture of the lithium ion secondary battery. The battery was tested according to the test m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com