Production method for Chinese chestnut full nutrition powder puffed food

A technology of puffed food and a production method, applied in the field of food processing, can solve the problems of indigestion and absorption of chestnut, restrict the production of chestnut, dark color of finished product, etc., and achieve the effects of filling a market gap, facilitating general promotion, and having unique taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A manufacturing method of milk-flavored chestnut slices, including the following steps:

[0027] (1) Ingredients: 40% chestnut whole nutrient powder, 15% konjac flour, 10% corn flour, 10% sweet potato starch, 10% glutinous rice flour, 8% flour as raw materials, supplemented by fresh milk powder 3%, chive powder 1.5 %, white sugar 2%, monosodium glutamate 0.5% are seasonings to mix, first add 50℃ warm water mixed with honey to the above mixture in a ratio of 1:1.1, stir and mix into a paste, then add 0.5% vegetable oil to the paste Mix with 0.05% emulsifier and 0.3% yeast foaming agent for 15 minutes. After mixing, let it stand for 10 minutes to obtain a dough mixture;

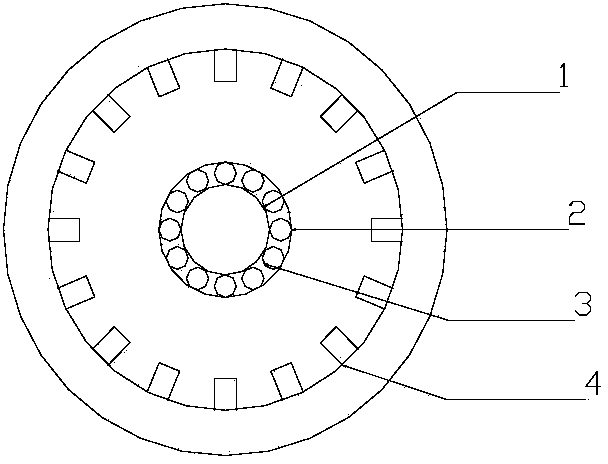

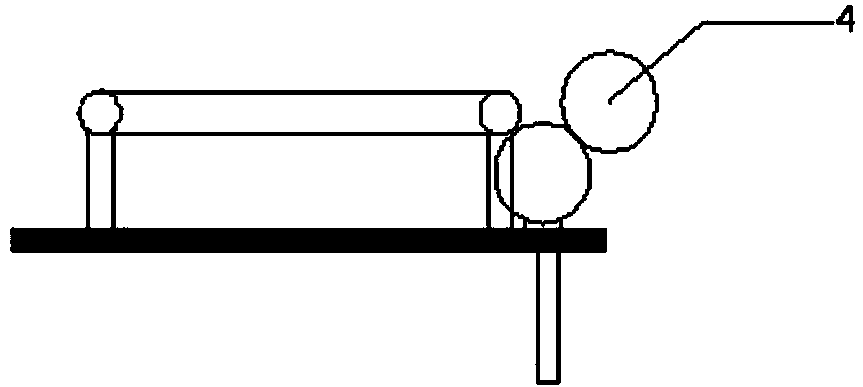

[0028] (2) Steaming and rolling: Put the above-mentioned dough mixture into a steamer and cook for 10 minutes; the dough that has matured to a certain extent is placed on the conveyor belt of rolling rollers equipped with flywheel bearings on both sides for repeated rolling;

[0029] The rolling roller is the ...

Embodiment 2

[0038] A method for making seaweed-flavored puffed chestnut strips includes the following steps:

[0039] (1) Ingredients: 40% chestnut whole nutrient powder, 10% konjac flour, 5% corn flour, 10% sweet potato starch, 10% glutinous rice flour, 10% flour as raw materials, supplemented by 10% seaweed fine powder, 2% white sugar , Table salt 2%, mustard powder 1% as seasonings to mix, first add 50℃ warm water mixed with honey to the above mixture at a ratio of 1:1.2 to make a paste, then add 0.8% vegetable oil and 0.07% emulsifier, and 0.5% yeast foaming agent. Stir for 10 minutes. After stirring, let it stand for 10 minutes to obtain a dough mixture fermented to a certain degree;

[0040] (2) Cooking and rolling: Put the above dough mixture into the steamer and cook for 15 minutes; the dough that has been matured to a certain extent is placed on the conveyor belt of rolling rollers equipped with flywheel bearings on both sides for repeated rolling;

[0041] The rolling roller is the s...

Embodiment 3

[0048] Since the chestnut itself has a unique chestnut fragrance, which is different from the potato itself without any fragrance, the original chestnut slice processing plan can be made to realize the preservation of its own unique fragrance. The specific implementation steps are as follows:

[0049] (1) Ingredients: 55% chestnut whole nutrient powder, 10% konjac flour, 5% corn flour, 10% sweet potato starch, 10% glutinous rice flour, 5% flour as raw materials, supplemented by 2.5% white sugar, 2% salt, and MSG Mix 0.5% as seasoning, first add 50℃ warm water mixed with honey to the above mixture at a ratio of 1:1.2 to form a paste, then add 1.0% vegetable oil and 0.1% emulsifier to the paste, and 0.35% yeast foaming agent. Stir for 15 minutes, and let stand for 8 minutes after stirring;

[0050] (2) Steaming and rolling: Put the above-mentioned dough mixture into the steamer and cook for 12 minutes; the dough that has been matured to a certain extent is placed on the conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com