Preparation method of cobalt nanosphere

A cobalt nanometer and cobalt chloride hexahydrate technology, which is applied in the field of preparation of cobalt nanospheres, can solve the problems of difficult control of product size and shape, harsh high-temperature reaction conditions, and complicated preparation process, and achieve simple equipment, low cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

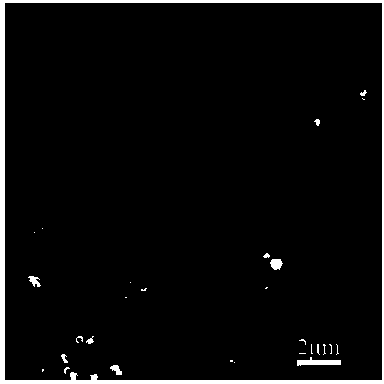

Image

Examples

Embodiment 1

[0028] The preparation method of the cobalt nanospheres of this embodiment comprises the following steps:

[0029] 1) Weigh 0.25 g of cobalt chloride hexahydrate and 0.05 g of polyvinylpyrrolidone and dissolve it in a mixture of 15 ml of deionized water and absolute ethanol to make solution A; weigh 0.4 g of sodium hydroxide and dissolve it in 5 ml of deionized Make solution B in water; then weigh 0.4 g sodium borohydride and dissolve in 5 ml deionized water to make solution C;

[0030] 2) Mix 15 ml of solution A, 5 ml of solution B and 5 ml of solution C as a reaction solution, transfer it to an autoclave, and place it in a constant temperature blast drying oven at 160 °C for 20 hours to obtain cobalt nanospheres;

[0031] 3) After the hydrothermal reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0032] 4) Dry the precipitate in a vacuum drying oven at 50 °C for 5 hours to obtain black cobalt pow...

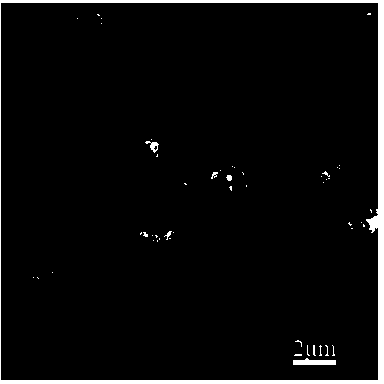

Embodiment 2

[0035] The preparation method of the cobalt nanospheres of this embodiment comprises the following steps:

[0036] 1) Weigh 0.25 g of cobalt chloride hexahydrate and 0.06 g of polyvinylpyrrolidone and dissolve it in a mixture of 15 ml of deionized water and absolute ethanol to make solution A; weigh 0.5 g of sodium hydroxide and dissolve it in 5 ml of deionized Water to make solution B; then weigh 0.62 g sodium borohydride and dissolve it in 5 ml deionized water to make solution C;

[0037] 2) 15 ml of solution A, 5 ml of solution B and 5 ml of solution C were mixed as a reaction solution and transferred to an autoclave, and placed in a constant temperature blast drying oven at 180 °C for 15 hours to obtain cobalt nanospheres;

[0038] 3) After the hydrothermal reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0039] 4) Dry the precipitate in a vacuum drying oven at 50 °C for 5 hours to obtain blac...

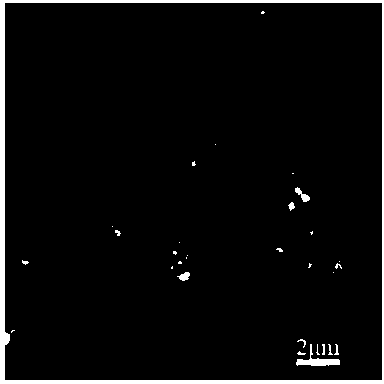

Embodiment 3

[0042] The preparation method of the cobalt nanospheres of this embodiment comprises the following steps:

[0043] 1) Weigh 0.25 g of cobalt chloride hexahydrate and 0.1 g of polyvinylpyrrolidone dissolved in a mixture of 15 ml of deionized water and absolute ethanol to make solution A; weigh 0.48 g of sodium hydroxide and dissolve in 5 ml of deionized Water to make solution B; then weigh 0.55 g sodium borohydride and dissolve it in 5 ml deionized water to make solution C;

[0044] 2) Mix 15 ml of solution A, 5 ml of solution B and 5 ml of solution C as a reaction solution, transfer it to an autoclave, and place it in a constant temperature blast drying oven at 180 °C for 18 hours to obtain cobalt nanospheres;

[0045] 3) After the hydrothermal reaction, centrifuge the suspended reaction solution, and then wash the precipitate with deionized water and absolute ethanol;

[0046] 4) Dry the precipitate in a vacuum drying oven at 40 °C for 6 hours to obtain black cobalt powder. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com