Method for manufacturing nitrogen-doped multi-wall carbon nano tube

A multi-walled carbon nanotube, nitrogen-doped technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of long process, poor uniform dispersion of elements, affecting material properties, etc., to avoid cumbersome steps, Good structure and morphology, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Specifically, the preparation method of the present invention includes: combining a mesoporous silica template with a three-dimensional cubic pore structure and without removing surfactants, and a nitrogen-containing macrocyclic iron complex as a carbon source, a nitrogen source, and an iron source at the same time through physical Mechanically mixing uniformly to make a mixture; heat-treating the mixture to make an iron oxide / N / carbon nanotube / silica template composite material; removing the silica template in the composite material with a strong base; and Iron oxides in the composite material are removed with strong acid to prepare the nitrogen-doped multi-walled carbon nanotubes.

[0022] More specifically, as an example, the preparation method of the present invention may include the following steps.

[0023] (1) Preparation of mesoporous silica template material (KIT-6 with three-dimensional cubic channel structure) according to prior art literature (such as Chem.C...

Embodiment 1

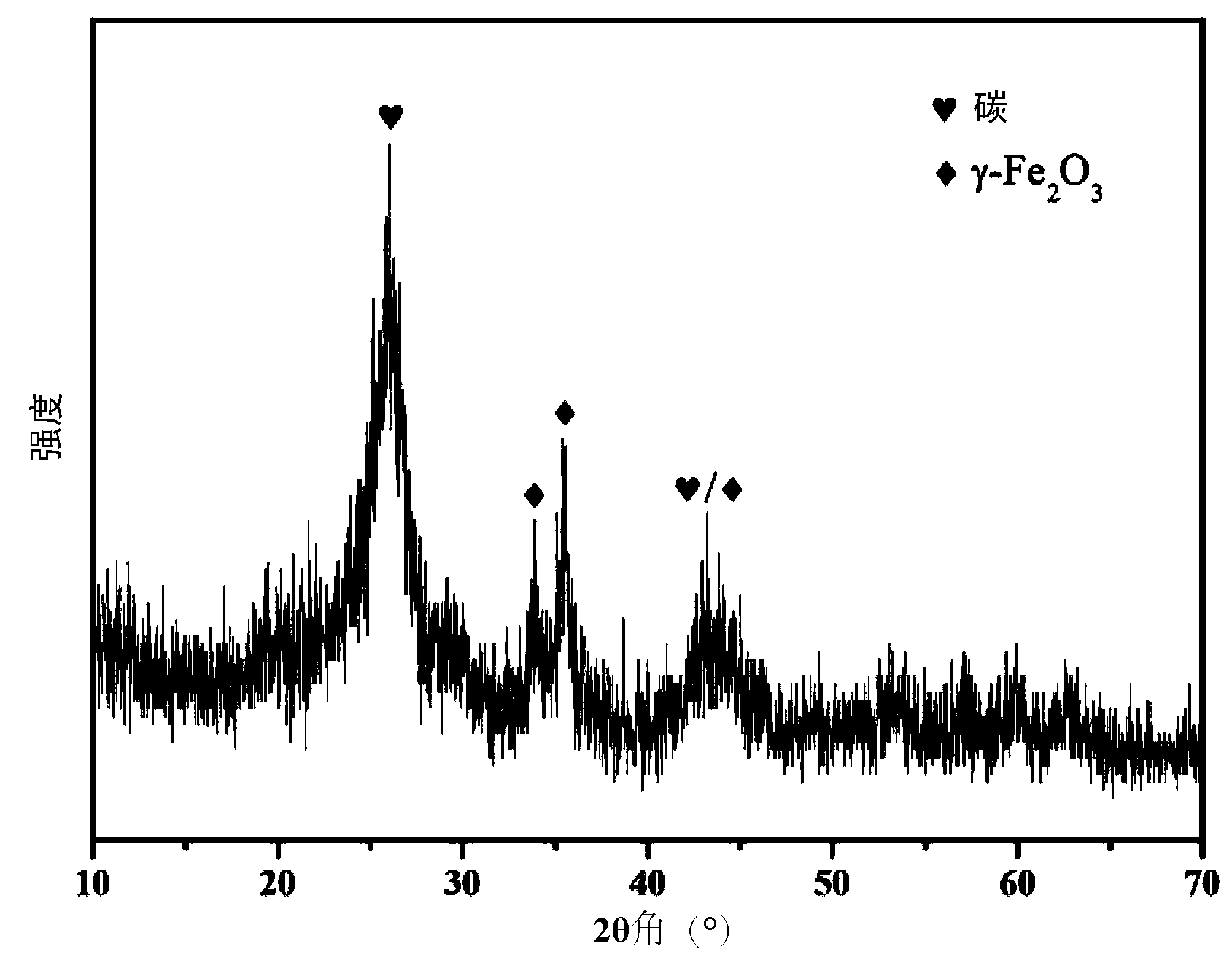

[0036] Described in accordance with the technical scheme and process flow. First, mesoporous silica (KIT-6) with a three-dimensional cubic mesoporous structure was prepared according to the literature, and KIT-6 without surfactant was used as a hard template material. First weigh 0.5g of iron phthalocyanine, and then take the mesoporous SiO prepared in the above step (1) without removing the surfactant 2 Mix 0.5g of the template material with the above powder, and mix it evenly with the help of physical mechanical mixing method to obtain the precursor SiO 2 Mixed material. Then, it was heated at 900°C in N 2 Heat treatment in the atmosphere for 10h to obtain the product SiO 2 of composite materials. The resulting composite was detemplated by 2M NaOH solution at 80 °C, followed by 2.6M HNO 3 Treat for 48h to remove FeO x catalyst. Then centrifuged, washed and dried to obtain nitrogen-doped multi-walled carbon nanotubes with good morphology. The prepared FeO x The wide-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com