Slagging agent for high-temperature oriented silicon steel heating furnace and preparation method of slagging agent

A technology for oriented silicon steel and slag agent, applied in the field of metallurgical industrial furnaces, can solve the problems of complex composition, high melting point, low heating capacity, etc., and achieve the effects of reducing reaction activity, reducing melting point of slag and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

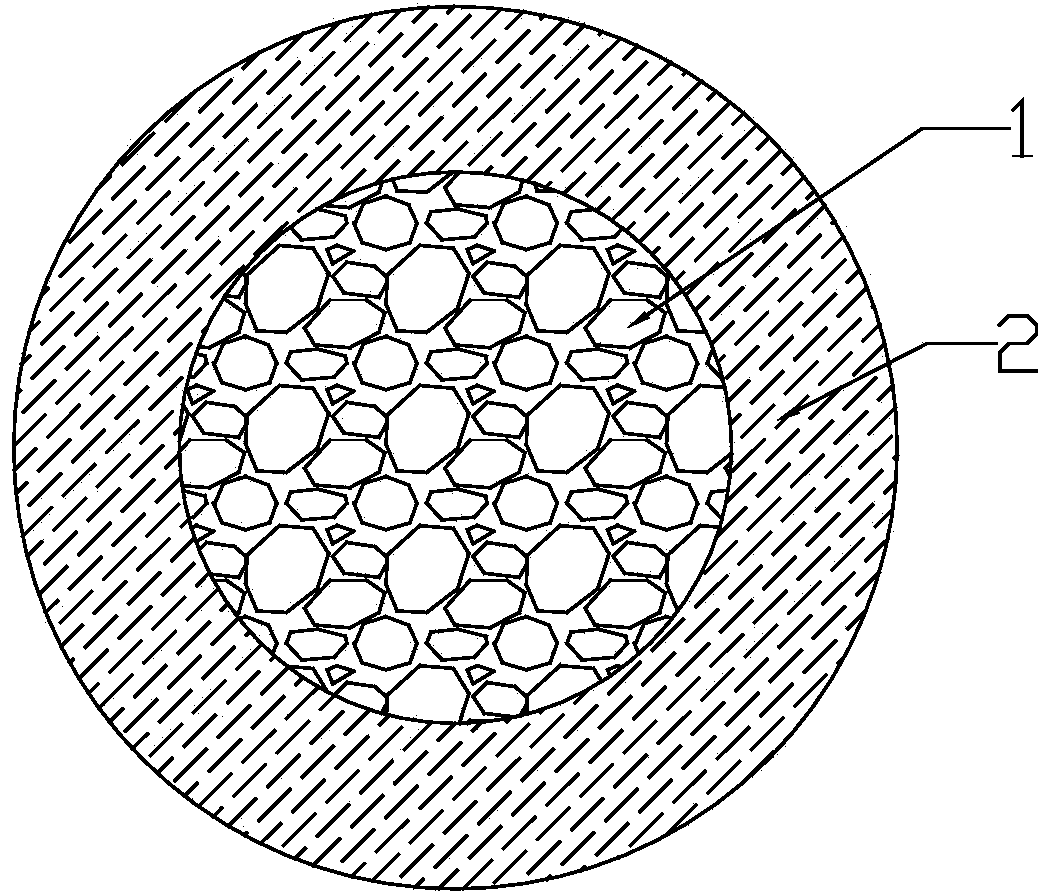

[0030] A preparation method of a high-temperature oriented silicon steel heating furnace slag agent:

[0031] 1) Weigh 18g of white sandstone, 25g of spodumene, 5g of active lime, 2g of instant powdered natron, 40g of fluorite, 5g of soda ash and 5g of borax, and add them to the mixer for stirring and dry mixing. Mix until uniform, get component B, set aside;

[0032] 2) Weigh 20g of charcoal and 80g of component B;

[0033] 3) Spray water to wet the charcoal, then gradually add wet charcoal and component B into the rotating disc pelletizer, and use charcoal as the core to cooperate with component B on the outer layer to make pellets;

[0034] 4) Dry the pellets obtained in step 3) to obtain a slagging agent with a particle size of 3-8 mm.

[0035] The diameter of charcoal particles is 2-5 mm, which can be purchased in the market; the SiO2 of white sandstone 2 Content ≥ 80%, particle size ≤ 0.15mm, origin is Jiangxia District, Wuhan City; Li 2 O content ≥ 0.75%, particle s...

Embodiment 2

[0037] Another preparation method of high temperature oriented silicon steel heating furnace slag agent:

[0038] 1) Weigh 25g of white sandstone, 18g of spodumene, 3g of active lime, 4g of instant powdered natron, 35g of fluorite, 10g of soda ash and 5g of borax, and add them to the mixer for stirring and dry mixing. Mix until uniform, get component B, set aside;

[0039] 2) Weigh 80g of coke and 20g of component B;

[0040] 3) Wet the coke with water, then gradually add the wet coke and component B into the rotating disc pelletizer, and use the coke as the core to cooperate with the outer component B to make pellets;

[0041] 4) Dry the pellets obtained in step 3) to obtain a slagging agent with a particle size of 3-8 mm.

[0042] The diameter of coke particles is 2-5mm, which is broken coke from the coking plant of iron and steel enterprises; SiO2 of white sandstone 2 Content ≥ 80%, particle size ≤ 0.15mm, origin is Jiangxia District, Wuhan City; Li 2 O content ≥ 0.75%, p...

Embodiment 3

[0044] The preparation method of the third high temperature oriented silicon steel heating furnace slag agent:

[0045] 1) Weigh 22g of white sandstone, 25g of spodumene, 4g of active lime, 3g of instant powdered natron, 38g of fluorite, 6g of soda ash and 2g of borax, and add them to the mixer for stirring and dry mixing. Mix until uniform, get component B, set aside;

[0046] 2) Weigh 40g of coke and 60g of component B;

[0047] 3) Wet the coke with water spray, then gradually add the wet coke and component B into the rotating disc pelletizer, and use the coke as the core to cooperate with the outer component B to make pellets;

[0048] 4) Dry the pellets obtained in step 3) to obtain a slagging agent with a particle size of 3-8mm.

[0049] The diameter of coke particles is 2-5mm, which is broken coke from the coking plant of iron and steel enterprises; SiO2 of white sandstone 2 Content ≥ 80%, particle size ≤ 0.15mm, origin is Jiangxia District, Wuhan City; Li 2 O conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com