Amphiphilic polymer and preparing method thereof

A technology of amphiphilic polymers and polymers, applied in pharmaceutical formulations, medical preparations with non-active ingredients, etc., can solve problems such as lack of pH responsiveness, and achieve good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

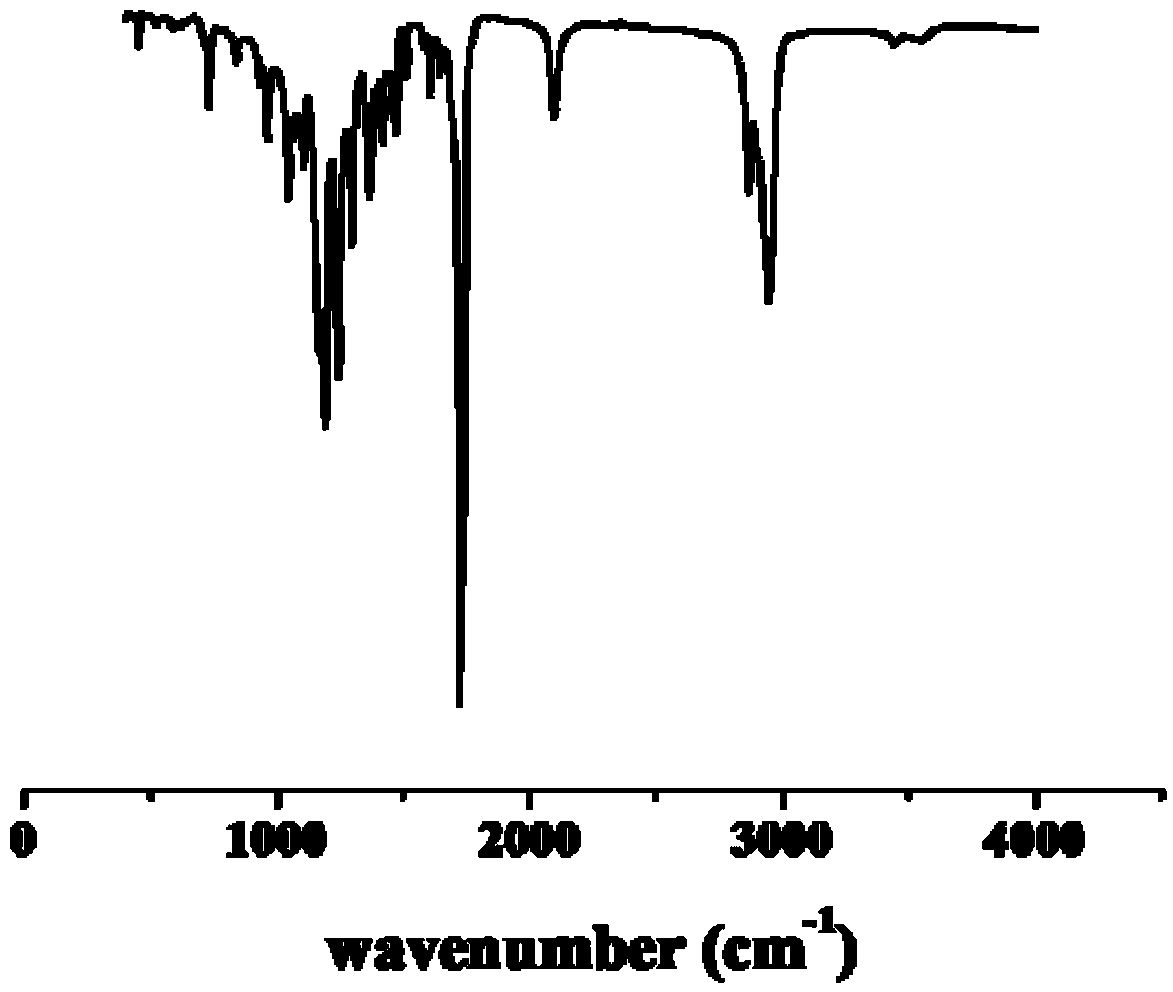

[0072]The present invention also provides a method for preparing an amphiphilic polymer, comprising: combining an azide-functionalized polymer having a structure of formula (II) with polyethylene glycol monomethyl ether having a structure of formula (III) Paragraph-poly(γ-propynyl-L-glutamate), cuprous bromide, and pentamethyldivinyltriamine are mixed and reacted in an organic solvent to obtain an amphiphilic compound with the structure of formula (I) Polymer; Concrete reaction process is as follows:

[0073]

[0074] The organic solvent is preferably nitrogen, nitrogen dimethylformamide.

[0075] In formula (I) and formula (III), m is the degree of polymerization, preferably, 45≤m≤245, more preferably, 80≤m≤200; n and o are the degree of polymerization, preferably, 10≤n+ o≤200, more preferably, 50≤n+o≤100.

[0076] In formula (II) and formula (I), R is preferably:

[0077]

[0078] Wherein, k is the degree of polymerization, preferably 5≤k≤50, more preferably 10≤k≤30...

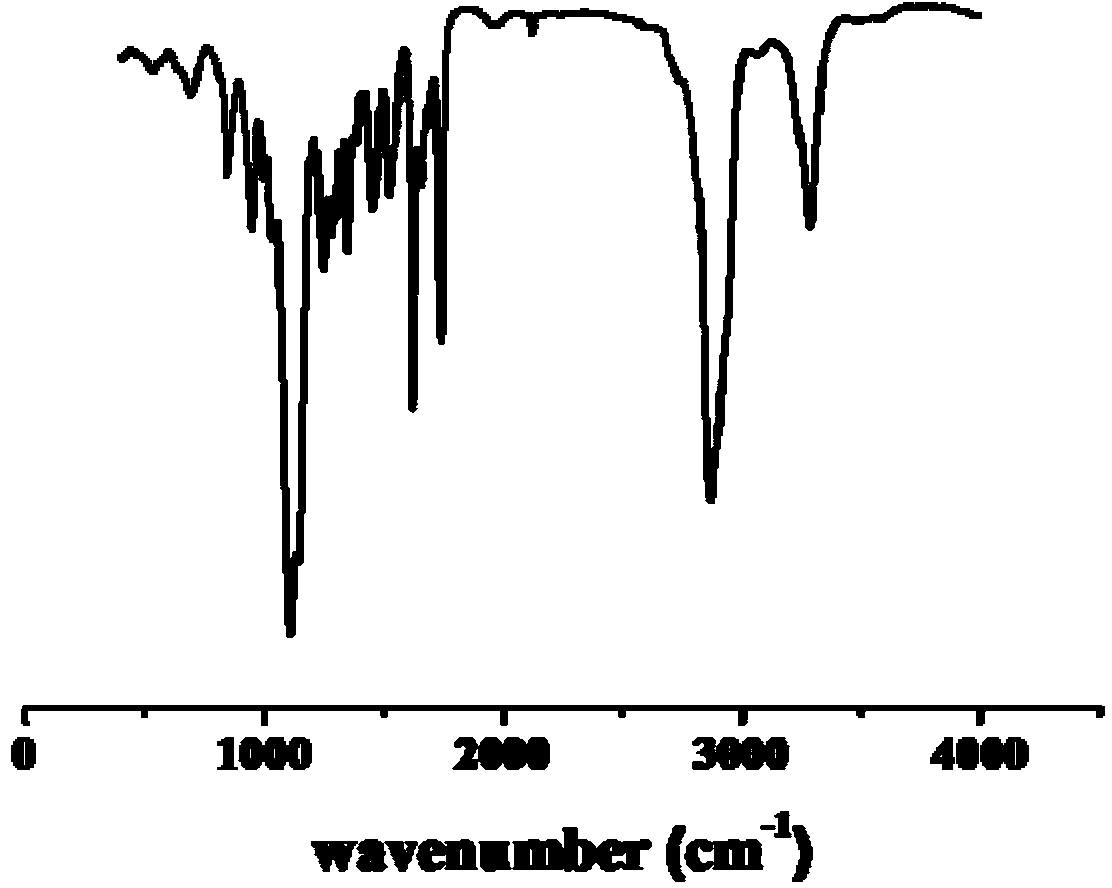

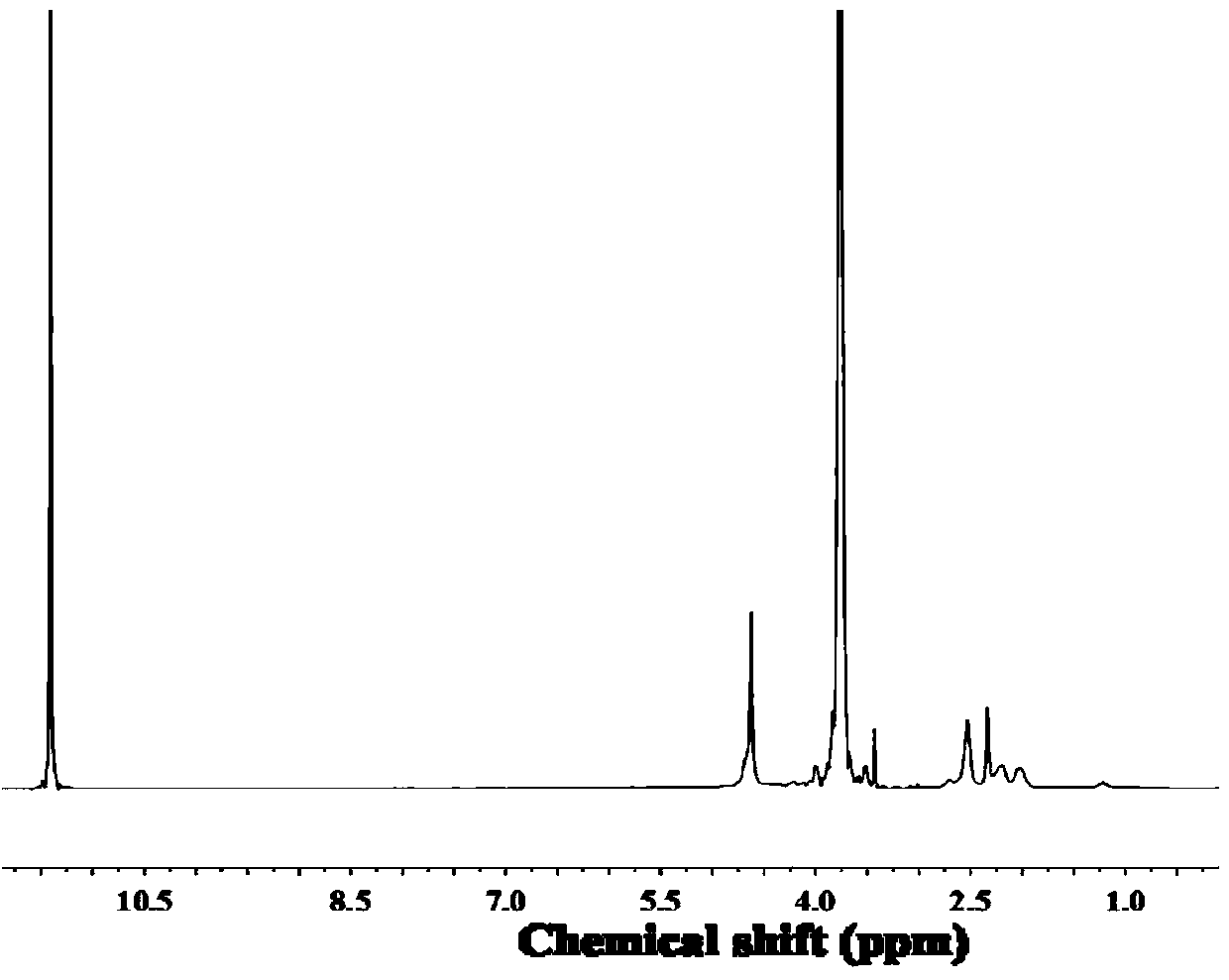

Embodiment 1

[0107] Mix 30 mL of propynyl alcohol with 20 g of L-glutamic acid, add 8 mL of concentrated sulfuric acid dropwise to the reaction system at 0°C, and complete the dropwise addition within 20 minutes, then stir the reaction overnight at room temperature. After the reaction, the reaction solution was poured into the sodium bicarbonate solution to obtain a white precipitate, which was recrystallized in water and filtered to obtain the product γ-propynyl-L-glutamate.

Embodiment 2

[0109] Mix 7.4 g of γ-propynyl-L-glutamate obtained in Example 1 with 3.96 g of triphosgene in 100 mL of dry tetrahydrofuran to obtain a suspension. Stir the reaction until the solution is clear, that is, the reaction is complete; after the reaction, settle the reaction system with 400mL of n-hexane, freeze it in a -20°C refrigerator overnight to obtain a layered solution, and then remove the upper layer of the layered solution Clear liquid, dissolve the yellow oily liquid in the lower layer in 100mL ethyl acetate, wash twice with 50mL ice water, then wash twice with 50mL cold 0.5wt% sodium bicarbonate aqueous solution, separate several layers, wash with anhydrous magnesium sulfate After drying overnight, the magnesium sulfate was removed by filtration, and the solution was spin-dried to obtain the product γ-propynyl-L-glutamic acid N-carboxyl internal anhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com