Preparation method of gas sensor array for detecting Jinhua hams

A gas sensor, Jinhua ham technology, applied in the field of gas sensors, can solve the problems of low sensitivity of organic gases, increase the sensor volume, low integration, etc., and achieve the effects of low cost, small impact and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

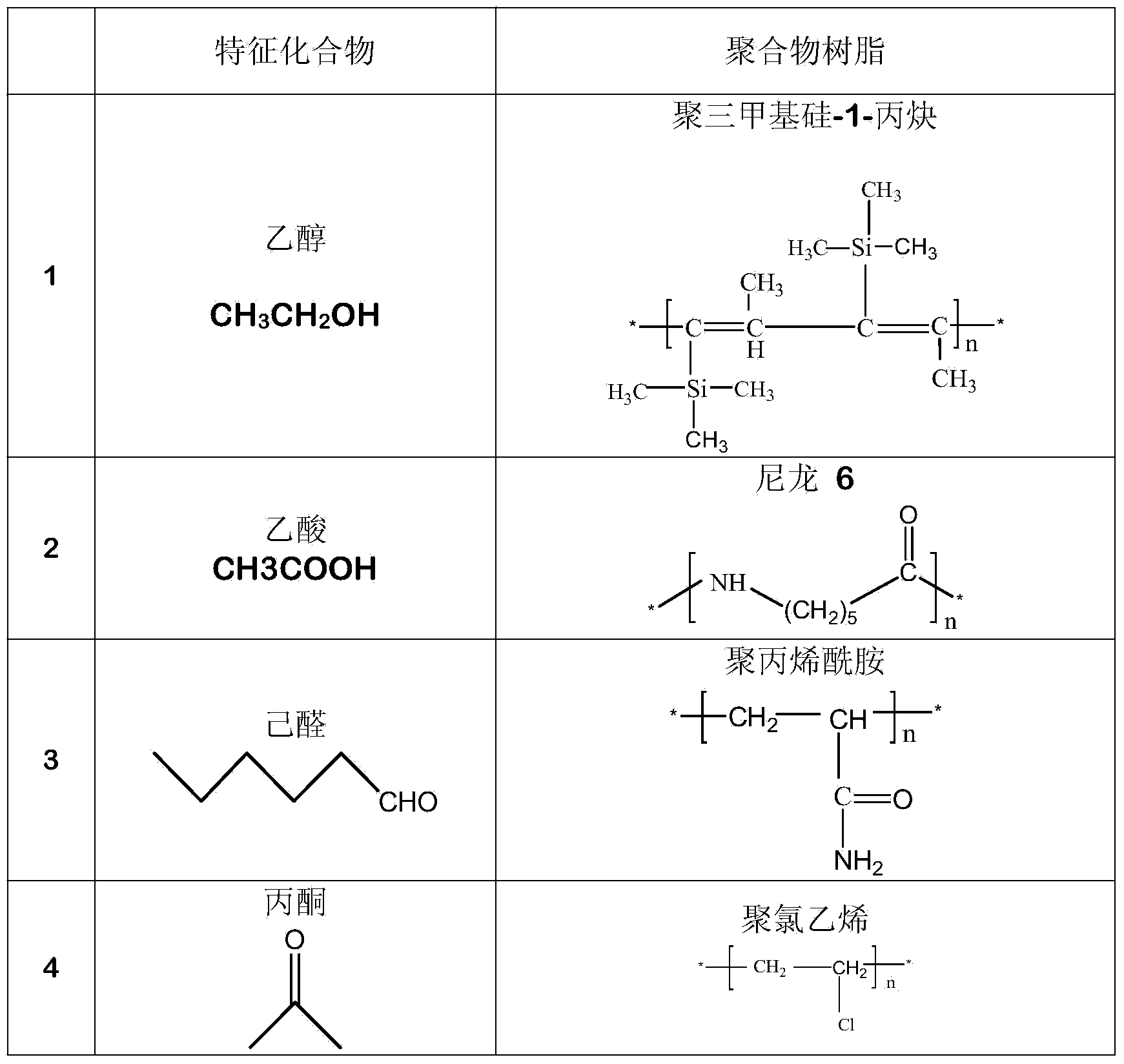

[0018] 1. Polytrimethylsilyl-1-propyne was purchased from Aladdin Reagent Co., Ltd., with a molecular weight of 500,000; ethanol was purchased from Aladdin Reagent Co., Ltd., which is an AR-grade pure reagent; nylon 6 was purchased from Alfa Aisha Chemical Co., Ltd. company, with a molecular weight of about 27,000; acetic acid was purchased from Bailingwei Technology Co., Ltd., with a purity of 99.8%; polyacrylamide was purchased from Bailingwei Technology Co., Ltd., with a molecular weight of 200,000; Vinyl chloride was purchased from Alfa Aisha Chemical Co., Ltd. with a molecular weight of 200,000; acetone was purchased from Alfa Aisha Chemical Co., Ltd. with a purity of 98%.

[0019] 2. Polytrimethylsilyl-1-propyne, nylon 6, polyacrylamide, and polyvinyl chloride were vapor-deposited on a circular quartz substrate with a diameter of 6 mm and a thickness of 0.8 mm on a UNIVEX-300 vacuum coating machine. The specific steps are as follows:

[0020] (1) Select a suitable subst...

Embodiment 2

[0033] 1. The reagents and polymer used are the same as those in Example 1.

[0034] 2. Polytrimethylsilyl-1-propyne, nylon 6, polyacrylamide, and polyvinyl chloride were vapor-deposited on a circular quartz substrate with a diameter of 8 mm and a thickness of 1 mm on a UNIVEX-300 vacuum coating machine. The specific steps are as follows:

[0035] (1) Select a suitable substrate holder to place the quartz substrate and polyacrylamide;

[0036] (2) Check the status of circulating cooling water, compressed air and high-purity nitrogen, and check the oil level of the mechanical pump and outlet oil mist filter;

[0037] (3) Turn the main power knob to the vertical position. After the self-test of the instrument is normal, close the bell cover, and pay attention to the position of the connecting rod on the left;

[0038] (4) Pass F 1 and F 5 Switch the display screen to the air extraction interface, start air extraction, and prohibit power failure after starting air extraction;...

Embodiment 3

[0048] 1. The reagents and polymer used are the same as those in Example 1.

[0049] 2. On the UNIVEX-300 vacuum coating machine, polytrimethylsilane-1-propyne, nylon 6, polyacrylamide, and polyvinyl chloride were vapor-deposited on a square with length × width = 8 × 8mm and a thickness of 0.8mm. On a quartz substrate, the specific steps are as follows:

[0050] (1) Select a suitable substrate holder to place the quartz substrate and polyacrylamide;

[0051] (2) Check the status of circulating cooling water, compressed air and high-purity nitrogen, and check the oil level of the mechanical pump and outlet oil mist filter;

[0052] (3) Turn the main power knob to the vertical position. After the self-test of the instrument is normal, close the bell cover, and pay attention to the position of the connecting rod on the left;

[0053] (4) Pass F 1 and F 5 Switch the display screen to the air extraction interface, start air extraction, and prohibit power failure after starting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com