Organic-inorganic ultrafiltration composite membrane and preparation method thereof

An ultrafiltration composite membrane, inorganic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The problem is to achieve the synergistic enhancement of mechanical properties and anti-pollution properties, enhance anti-pollution properties, and improve mechanical properties and anti-pollution properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

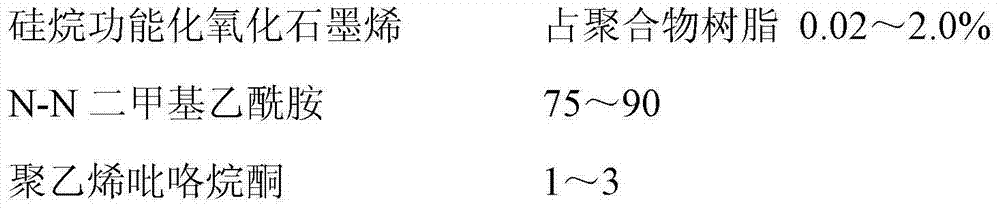

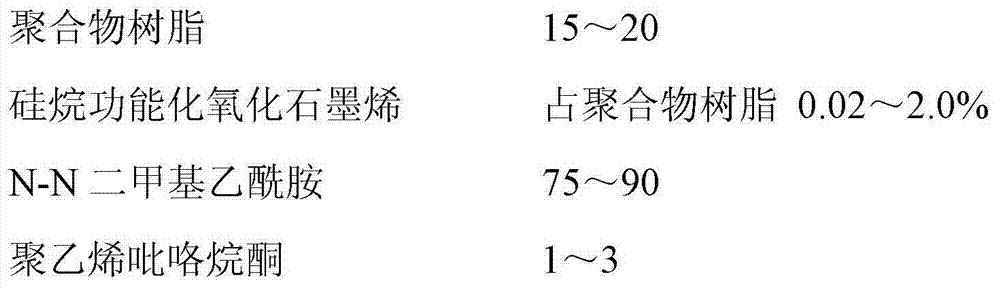

Embodiment 1

[0017] 0.075g of γ-aminopropyltriethoxysilane functionalized graphene oxide was ultrasonically dispersed in 84g of NN dimethylacetamide as a solvent. After 2h, 15g of polyvinylidene fluoride and 1g of polyvinylpyrrolidone as a porogen were added. , Then heat and stir in a 450℃ water bath for 24h, stand still for 24h, use a self-made scraper to control a certain liquid film thickness and scrape the film on a clean glass plate, pre-evaporate for 30 seconds, immerse in deionized water to solidify, and repeat The water is changed to remove the solvent and the porogen, and finally the silane-functionalized graphene oxide modified organic-inorganic ultrafiltration composite membrane can be produced.

[0018] The above-mentioned organic-inorganic ultrafiltration composite membrane was soaked in deionized water for 3 days, and then the mechanical strength and anti-fouling performance of the ultrafiltration composite membrane were tested by a mechanical stretching device and a permeation f...

Embodiment 2

[0020] 0.15g γ-aminopropyltriethoxysilane functionalized graphene oxide was ultrasonically dispersed in 83g NN dimethylacetamide, 15g polyacrylonitrile and 1g polyvinylpyrrolidone were added after 1h, and then heated in a water bath at 50℃ Stir for 30h, let stand for 24h, use a self-made scraper to control a certain liquid film thickness and scrape the film on a clean glass plate, pre-evaporate for 30 seconds, immerse in deionized water for solidification, and repeatedly change the water to remove the solvent and porogen , And finally the silane functionalized graphene oxide modified organic-inorganic ultrafiltration composite membrane can be made.

[0021] The above-mentioned organic-inorganic ultrafiltration composite membrane was soaked in deionized water for 4 days, and then the mechanical strength and anti-pollution performance of the ultrafiltration composite membrane were tested by a mechanical stretching device and a permeation filtration device. The results showed that th...

Embodiment 3

[0023] 0.1g γ-aminopropyltriethoxysilane functionalized graphene oxide was ultrasonically dispersed in 77g NN dimethylacetamide, 20g polysulfone and 3g polyvinylpyrrolidone were added after 2h, and then heated and stirred in a water bath at 40℃ 20h, let it stand for 30h, use a self-made scraper to control a certain liquid film thickness and scrape the film on a clean glass plate. After pre-evaporating for 30 seconds, it is immersed in deionized water to solidify, and the water is changed repeatedly to remove the solvent and porogen. Finally, the silane-functionalized graphene oxide modified organic-inorganic ultrafiltration composite membrane can be produced.

[0024] The above-mentioned organic-inorganic ultrafiltration composite membrane was soaked in deionized water for 4 days, and then the mechanical strength and anti-pollution performance of the ultrafiltration composite membrane were tested by a mechanical stretching device and a permeation filtration device. The results sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com