A method for producing gas by grinding and extruding straw and shaving coal columnar particles instead of lump coal

A technology that replaces blocks and granules. It is applied in the direction of raw material extrusion granulation, mold extrusion granulation, and production of combustible gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

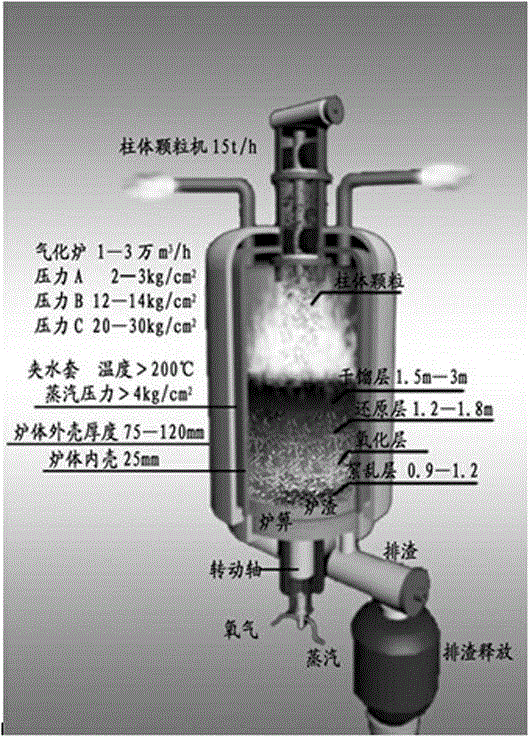

[0094] A method for producing gas by crushing and extruding straw and coal foam cylinder particles instead of lump coal, the steps of crushing and extruding straw and coal foam into cylinder particles at high temperature:

[0095] 1. Preparation of columnar particles

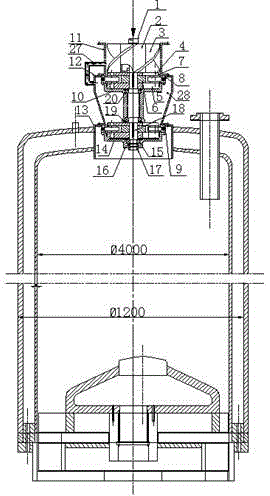

[0096] (1.1) Put the overall structure of the lower half of the roller pellet extruder into the upper end of the gas generator for sealing connection, so that the gas at a temperature of 300-900°C in the furnace will affect the lower die plate 14, orifice plate 8 and die hole 9 of the roller pellet extruder. Direct heating to maintain the temperature, and at the same time, the gas at a temperature of 300-900°C in the furnace heats the outer cylinder 12 of the roller pellet extruder, and makes the temperature in the working chamber 28 also reach 300-600°C to keep heating the fuel to be extruded;

[0097] (1.2) Put the crushed straw with a water content of 15-30%, and put the minced coal sieved with a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com