Method for preparing high-purity nanometer copper by using printed circuit board alkaline etching waste liquid

A technology for printed circuit boards and etching waste liquid, applied in nanotechnology and other directions, can solve the problems of low cost performance of recycled materials, limited large-scale use, low recovery rate, etc., to achieve good anti-oxidation performance, not harsh process conditions, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

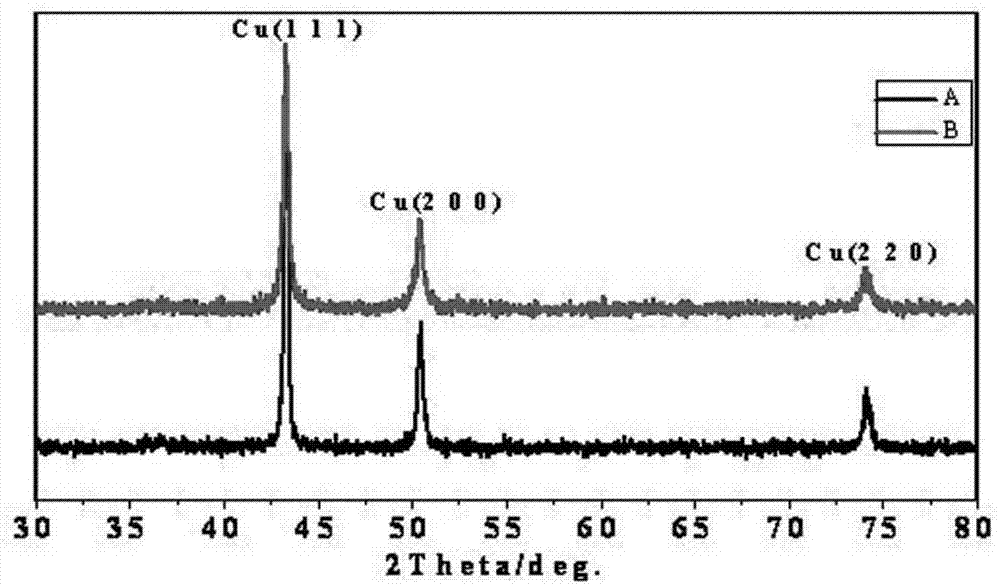

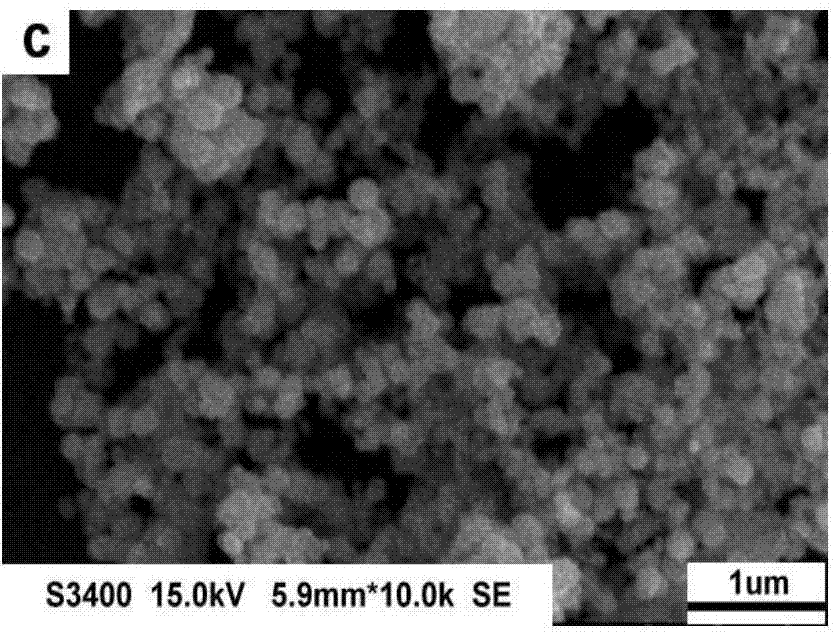

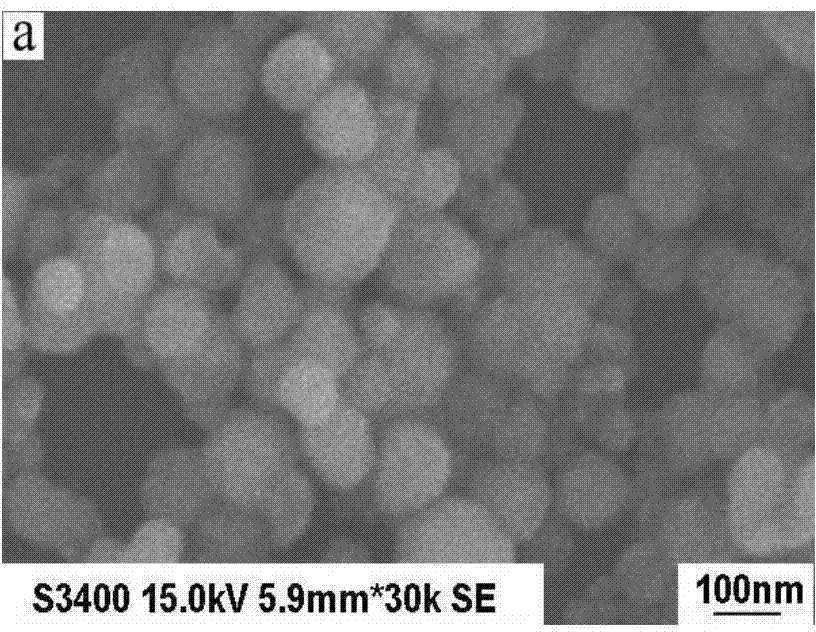

Embodiment 1

[0026] Take 50 milliliters of alkaline etching waste liquid and put it into two 25 milliliter centrifuge tubes, and centrifuge; after centrifugation, pour the supernatant liquid of the centrifuge tube into a 200 milliliter beaker, add 5 grams of polyvinylpyrrolidone and 5 grams of ten Hexaalkyltrimethylammonium bromide is used as reactant A solution; Preparation contains 0.1 mol / liter hydrazine hydrate, 0.5 mol / liter gram of sodium hydroxide, 50 milliliters of B solution of 1 mol / liter polyethylene glycol; Pour the solution into the three-necked bottle, adjust the temperature of the constant temperature water bath at 80°C, start stirring, and the stirring speed is about 200 rpm, add solution A dropwise into the three-necked bottle, take it out after the reaction and cool it to room temperature; The solution is poured into two 50 ml centrifuge tubes and centrifuged again to collect the substance in the gel state of the lower layer in the centrifuge tube, and the upper layer is r...

Embodiment 2

[0028] Get 50 milliliters of alkaline etching waste liquid and put it into two 25 milliliter centrifuge tubes, and centrifuge; after centrifugation, pour the supernatant liquid of the centrifuge tube into a 200 milliliter beaker, add 8 grams of polyvinylpyrrolidone and 8 grams of ten Hexaalkyltrimethylammonium bromide is used as reactant A solution; Preparation contains 0.5 mol / liter of hydrazine hydrate, 0.5 mol / liter of sodium hydroxide, 50 milliliters of B solution of 1 mol / liter of polyethylene glycol; Pour the B solution into the three-necked bottle, adjust the temperature of the constant temperature water bath at 90°C, start stirring, and the stirring speed is about 200 rpm, add the A solution dropwise into the three-necked bottle, take it out after the reaction and cool it to room temperature; the reaction of cooling to room temperature Pour the solution into two 50ml centrifuge tubes for centrifugation, collect the substance in the gel state in the lower layer of the ce...

example 3

[0030] Get 100 milliliters of alkaline etching waste liquid and put it into two 50 milliliter centrifuge tubes, and centrifuge; after centrifugation, pour the supernatant liquid of the centrifuge tube into a 200 milliliter beaker, add 8 grams of polyvinylpyrrolidone and 8 grams of ten Hexaalkyltrimethylammonium bromide is used as reactant A solution; Preparation contains 0.25 mol / liter hydrazine hydrate, 1.0 mol / liter gram of sodium hydroxide, 50 milliliters of B solution of 2 mol / liter polyethylene glycol; Pour the solution into the three-necked bottle, adjust the temperature of the constant temperature water bath at 90°C, start stirring, and the stirring speed is about 200 rpm, add solution A dropwise into the three-necked bottle, and take out the reaction solution cooled to room temperature after the reaction; Pour into three 50ml centrifuge tubes for centrifugation, collect the gel state substance in the lower layer of the centrifuge tube, and recover the upper layer liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com