Composite scale and corrosion inhibitor and preparation method thereof

A scale and corrosion inhibitor, phosphorus-free scale inhibition technology, applied in chemical instruments and methods, complex/solubilizer treatment, scale removal and water softening, etc., can solve problems such as aggravating environmental deterioration and achieve biodegradability high, high-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

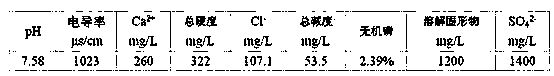

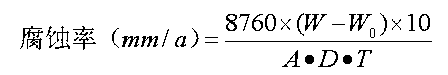

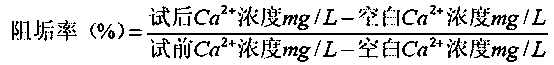

Examples

Embodiment 1

[0016] Agent A: Polyepoxysuccinic acid 30g, sodium molybdate 40g, acrylic acid-acrylate-sulfonate terpolymer (AA-AMPS) 170g, acrylic acid-sulfonic acid copolymer (AA-SA) 80g, benzotri Nitroxazole 10g, deionized water 670g;

[0017] Agent B: 120g sodium gluconate, 280g zinc sulfate, 30g concentrated sulfuric acid, 570g deionized water.

[0018] Preparation method: Take two 250ml beakers respectively, rinse the beakers, add the materials into the beakers according to the above proportions to prepare agent A and agent B, then mix, stir evenly, and then pour it into the sample storage bottle. Store in a cool and ventilated place.

Embodiment 2

[0020] Agent A: polyepoxysuccinic acid 40g, sodium molybdate 32g, acrylic acid-acrylate-sulfonate terpolymer (AA-AMPS) 150g, acrylic acid-hydroxypropyl acrylate copolymer (AA-HPA) 150g, benzene Triazole 7g, deionized water 230.5g;

[0021] Agent B: 80g of sodium gluconate, 200g of zinc sulfate, 10g of concentrated sulfuric acid, and 710g of deionized water.

[0022] The specific preparation method of the medicament is the same as in Example 1.

Embodiment 3

[0024] Agent A: polyepoxysuccinic acid 45g, sodium molybdate 20g, acrylic acid-hydroxypropyl acrylate copolymer (AA-HPA) 140g, acrylic acid-sulfonic acid copolymer (AA-SA) 100g, benzotriazole 13g, 682g of deionized water;

[0025] Agent B: sodium gluconate 100g, zinc sulfate 250g, concentrated sulfuric acid 20g, deionized water 630g.

[0026] The specific preparation method of the medicament is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com