Technology for realizing zero discharge of waste water caused by white carbon black production

A technology for the production of waste water and white carbon black, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, alkali metal sulfite/sulfate dehydration, etc., which can solve environmental impact and other problems and reduce labor costs. The effect of load, economic benefit and high degree of self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

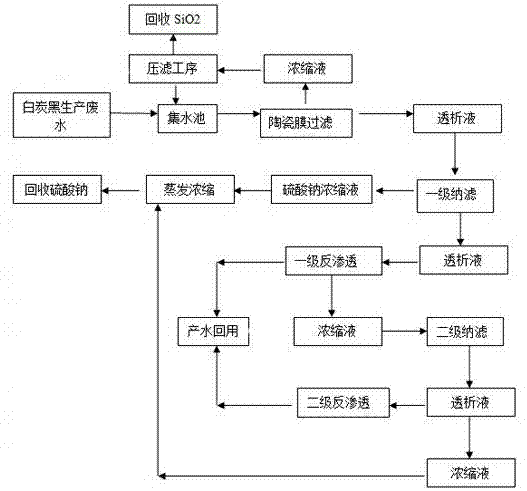

[0023] Such as figure 1 Shown, a kind of white carbon black production wastewater zero-discharge process comprises the steps:

[0024] Step 1, the white carbon black production waste water is firstly filtered by a ceramic membrane to obtain a ceramic membrane dialysate and a ceramic membrane concentrate;

[0025] Step 2: The ceramic membrane concentrate is subjected to plate and frame pressure filtration, and the filter residue is silica, which is recycled, and the pressure filtration water enters the collection pool for recycling;

[0026] Step 3: The ceramic membrane dialysate is subjected to primary nanofiltration, and the concentrated solution of the primary nanofiltration is collected to obtain a sodium sulfate concentrated solution, which is evaporated and concentrated to obtain sodium sulfate;

[0027] Step 4: The primary nanofiltratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com