Special compound microorganism bacterial fertilizer for peanuts and production method thereof

A technology of compound microorganisms and compound microorganisms, which is applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., to achieve the effects of being conducive to growth, changing the micro-ecological environment, and eliminating soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

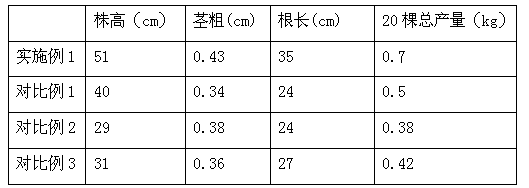

Examples

Embodiment 1

[0052] Preparation of Bacillus licheniformis bacterial agent:

[0053] Liquid submerged fermentation culture, inoculate the Bacillus licheniformis into the sterilized fermenter, the fermentation medium is: 0.5% starch, 0.03% yeast extract, 0.5% soybean meal, 0.2% urea, 0.5% dipotassium hydrogen phosphate, phosphoric acid Potassium dihydrogen 0.25%, magnesium sulfate 0.1%, manganese sulfate 0.01%, pH 7.0, fermentation conditions: the initial aeration ratio is 1:0.5, the culture temperature is 37°C, the stirring speed is 150rpm, and the dissolved oxygen is not less than 30%. The pH value is not lower than 6.5, and the stirring culture is carried out for 7 hours to make the viable bacteria content reach 10 10 pfu / ml, add disodium hydrogen phosphate and calcium chloride to the fermented liquid to flocculate. After the flocculation is completed, the plate and frame filter method is used to obtain the bacteria sludge. The bacteria sludge is blown and dried at 45-50°C to a water cont...

Embodiment 2

[0086] Preparation of Bacillus licheniformis bacterial agent:

[0087] Liquid submerged fermentation culture, inoculate the Bacillus licheniformis into the sterilized fermenter, the fermentation medium is: 0.2% starch, 0.01% yeast extract, 0.2% soybean meal, 0.1% urea, 0.2% dipotassium hydrogen phosphate, phosphoric acid Potassium dihydrogen 0.1%, magnesium sulfate 0.05%, manganese sulfate 0.006%, pH 6.8, fermentation conditions: initial aeration ratio is 0.9, culture temperature 35°C, stirring speed 100rpm, dissolved oxygen not less than 30%, pH value Not lower than 6.5, stirred for 6 hours to make the live bacteria content reach 10 10 pfu / ml, add disodium hydrogen phosphate and calcium chloride to the fermented liquid for flocculation. After the flocculation is completed, the plate and frame filter method is used to obtain the bacterial sludge. The bacterial sludge is blown and dried at about 45°C to a water content of 25%, and the bacterial powder is separated by a cyclone....

Embodiment 3

[0094] Preparation of Bacillus licheniformis bacterial agent:

[0095] Liquid submerged fermentation culture, inoculate the Bacillus licheniformis into the sterilized fermenter, the fermentation medium is: 0.8% starch, 0.06% yeast extract, 0.8% soybean meal, 0.4% urea, 0.8% dipotassium hydrogen phosphate, phosphoric acid Potassium dihydrogen 0.5%, magnesium sulfate 0.15%, manganese sulfate 0.012%, pH 7.2, fermentation conditions: the initial aeration ratio is 1:0.5, the culture temperature is 40°C, the stirring speed is 200rpm, and the dissolved oxygen is not less than 30%. The pH value is not lower than 6.5, and the stirring culture is carried out for 8 hours to make the viable bacteria content reach 10 10 pfu / ml, the fermented liquid was obtained by adding disodium hydrogen phosphate and calcium chloride for flocculation. After the flocculation was completed, the plate and frame filter method was used to obtain the bacterial sludge. The bacterial sludge was air-dried at 50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com