New method for performing preliminary condensation refrigeration on coking raw gas

A technology for condensing and cooling raw gas, which is applied in the direction of gas purification of condensed non-gaseous materials, gas dust removal, and climate sustainability. The effect of arranging the production environment, improving the production environment, and extending the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

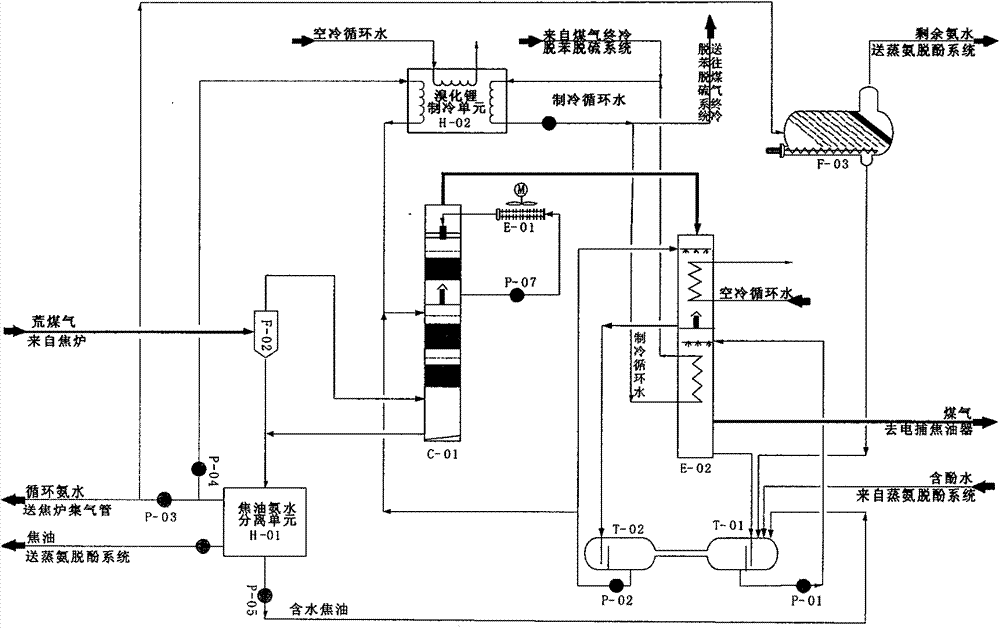

[0017] figure 1 It shows the primary condensation and cooling process of coking waste gas described in Example 1 of the present invention. The process is mainly composed of gas-liquid separator F-02, direct cooling tower C-01, closed air cooler E-01, horizontal tube primary cooler E-02, condensation tank T-01 in the lower section of the primary cooler, and upper section of the primary cooler Condensation tank T-02, residual ammonia water degreaser F-03, ammonia water and tar separation unit H-01, lithium bromide refrigeration unit H-02, related delivery pumps and related process pipelines.

[0018] The raw coking gas at about 81°C from the coke oven is first separated from gas and liquid by F-02, and then passes through the direct cooling tower C-01 from bottom to top. Layer filler. In the lower section of the direct cooling tower, the raw coal gas with a higher temperature is in countercurrent contact with the circulating ammonia water at a lower temperature from the H-02 l...

Embodiment 2

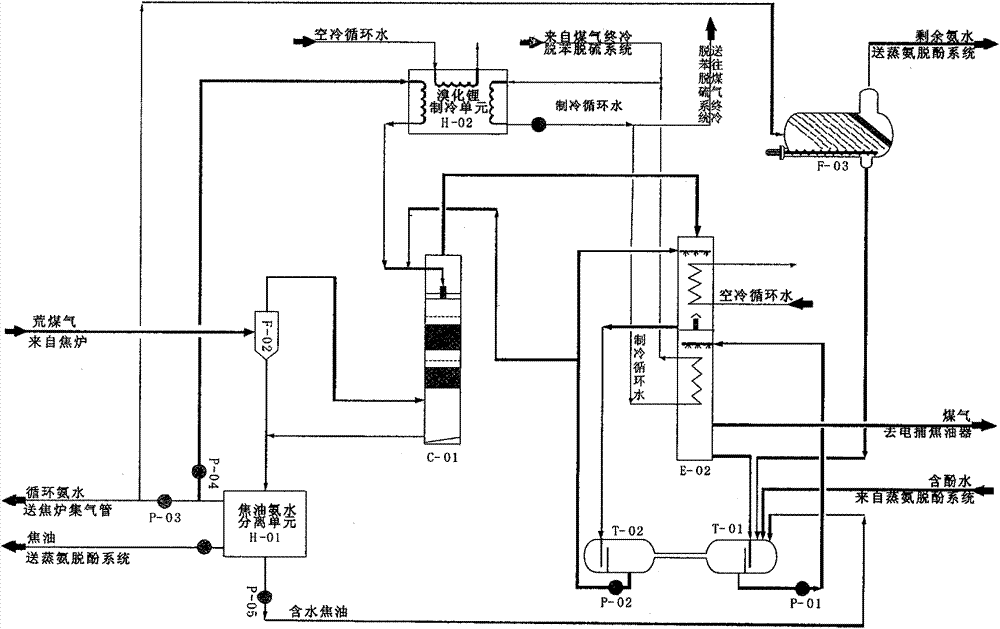

[0022] Such as figure 2 The shown embodiment 2 differs from embodiment 1 in that: the C-01 direct cooling tower is a two-layer packed tower without a closed air cooling cycle cooling section, and the direct cooling equipment and process are relatively simple; other equipment and processes Process is identical with embodiment 1.

[0023] Compared with the traditional process, in Example 2 of the present invention, the cooling load of the upper stage of the horizontal tube primary cooler is reduced by about 55%, so the water saving of the primary gas cooling is more significant; the condensation heat of raw gas from 80°C to 70°C is used for lithium bromide refrigeration , with an annual output of 2 million cokes, about 385,000 tons of steam can be saved each year, so the energy-saving effect is outstanding.

Embodiment 3

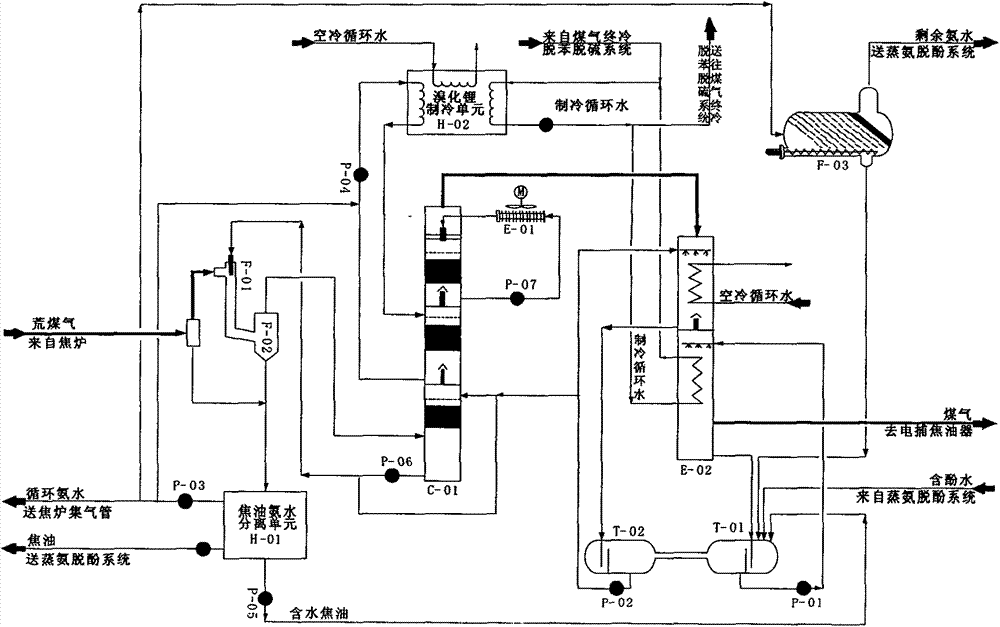

[0025] Such as image 3 Shown embodiment 3 differs from embodiment 1 in that: (1), C-01 direct cooling tower is a three-section three-layer packed tower. (2) There are two levels of washing and dust removal for raw coal gas: the first level, in the F-01 pipeline scrubber, uses the washing liquid from the lower section of the C-01 direct cooling tower to wash the raw coal gas from the coke oven downstream The second stage, in the lower section of the direct cooling tower, uses the liquid overflowing from the broken tray in the middle section of the direct cooling tower and the oil-water mixture pumped by the upper section of the P-02 primary cooler to wash and remove dust through the P-06 cycle The pump is used for countercurrent washing and dust removal of the gas from the F-02 gas-liquid separator. (3) For the preheating utilization of raw coal gas, the circulating ammonia water containing light tar, which has passed through the middle section of the direct cooling tower and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com