Device for generating high-efficiency multi-wavelength ultra-short pulse lasers

A technology of ultra-short pulse laser and generating device, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems affecting Stokes light conversion efficiency and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

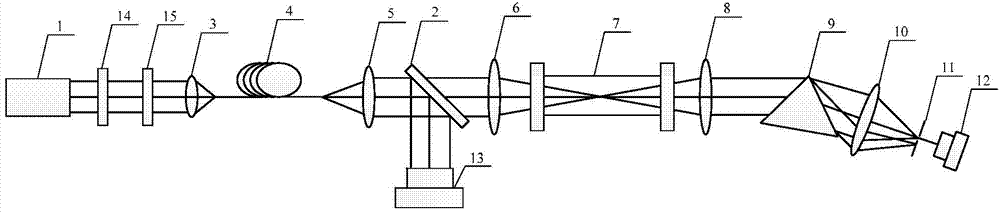

[0014] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode, the high-efficiency multi-wavelength ultrashort pulse laser generating device described in this embodiment mode, it comprises laser device 1, spectrometer 2, first focusing mirror 3, quartz optical fiber 4, second focusing mirror 5, the third focusing Mirror 6, Raman cell 7, fourth focusing mirror 8, equilateral dispersion prism 9, fifth focusing mirror 10, mode selection diaphragm 11, first detector 12, second detector 13, frequency doubling crystal 14 and filter light sheet 15;

[0015] The first focusing mirror 3, the quartz optical fiber 4, the second focusing mirror 5, the beam splitter 2, the third focusing mirror 6, the Raman cell 7, the fourth focusing mirror 8, the frequency doubling crystal 14 and the optical filter 15 are sequentially Set on the optical axis of the laser beam output by the laser 1, the laser beam output by the laser 1 is frequency-multiplied b...

specific Embodiment approach 2

[0023] Specific embodiment two: This embodiment further defines the high-efficiency multi-wavelength ultrashort pulse laser generating device described in specific embodiment one. In this embodiment, the laser 1 is a titanium sapphire femtosecond laser, and the laser 1 emits The wavelength of the laser beam is 800nm, and the pulse width is 50fs.

specific Embodiment approach 3

[0024] Specific embodiment three: This embodiment further limits the high-efficiency multi-wavelength ultrashort pulse laser generating device described in specific embodiment one. In this embodiment, the frequency doubling crystal 14 is converted into two kinds of lasers with mixed wavelengths after frequency doubling One beam has a wavelength of 400nm and a pulse width of 70fs; the other beam has a wavelength of 800nm and a pulse width of 50fs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com