Preparation method for marine shellfish beverage

A shellfish and seafood technology, applied in food preparation, food ingredients containing natural extracts, food ingredients as taste improvers, etc., can solve the problems of complex production process, high cost, long time required, etc., and achieve simple process flow , short cycle, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

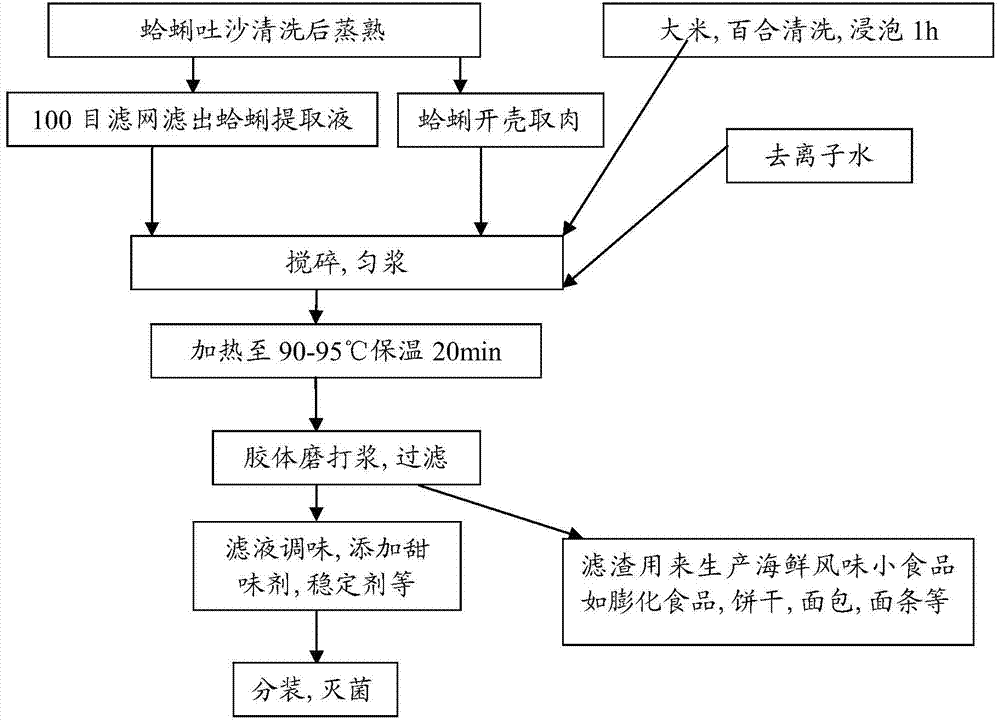

[0019] Implementation mode 1: if figure 1 as shown,

[0020] Step 1) Pre-treatment of raw materials: Take clams, after desanding and cleaning, steam them, filter out the clam extract with a 100-mesh filter, remove the shells from the remaining steamed clams; take rice and dried lilies, wash them, Soak for 1h;

[0021] Step 2) Deodorization: take 30kg of clam shellfish obtained in step 1), 15kg of clam extract, 30kg of rice, and 4kg of lily, and mix them to obtain raw materials; add 79kg of deionized water to the raw materials, and heat to Keep warm at 95°C for 25 minutes until the rice is gelatinized;

[0022] Step 3) Extraction and filtration: beat the product obtained in step 2) with a colloid mill, filter, and take the filtrate;

[0023] Step 4) Add additives: Add 8kg of sweetener, 0.5kg of compound stabilizer and 0.1kg of emulsifier to the filtrate obtained in step 3), and stir evenly;

[0024] Step 5) Subpackage and sterilize: Subpackage and sterilize the liquid obtai...

Embodiment approach 2

[0026] Step 1) Pre-treatment of raw materials: Take clams, after desanding and cleaning, steam them, filter out the clam extract with a 100-mesh filter, remove the shells from the remaining steamed clams; take rice and dried lilies, wash them, Soak for 1h;

[0027] Step 2) Deodorization: Take 35kg of clam shell meat obtained in step 1), 10kg of clam extract, 35kg of rice, and 3kg of lily, and mix them to obtain raw materials; add 83kg of deionized water to the raw materials, and heat to Keep warm at 95°C for 25 minutes until the rice is gelatinized;

[0028] Step 3) Extraction and filtration: beat the product obtained in step 2) with a colloid mill, filter, and take the filtrate;

[0029] Step 4) Add additives: Add 8kg of sweetener, 0.5kg of compound stabilizer and 0.1kg of emulsifier to the filtrate obtained in step 3), and stir evenly;

[0030] Step 5) Subpackage and sterilize: Subpackage and sterilize the liquid obtained in step 4) to obtain clam shellfish beverage B.

Embodiment approach 3

[0032] Step 1) Pre-treatment of raw materials: Take clams, after desanding and cleaning, steam them, filter out the clam extract with a 100-mesh filter, remove the shells from the remaining steamed clams; take rice and dried lilies, wash them, Soak for 1h;

[0033] Step 2) Deodorization: Take 25kg of clam shellfish obtained in step 1), 15kg of clam extract, 25kg of rice, and 5kg of lily, and mix them to obtain raw materials; add 70kg of deionized water to the raw materials, and heat to Keep warm at 95°C for 25 minutes until the rice is gelatinized;

[0034] Step 3) Extraction and filtration: beat the product obtained in step 2) with a colloid mill, filter, and take the filtrate;

[0035] Step 4) Add additives: Add 8kg of sweetener, 0.5kg of compound stabilizer and 0.1kg of emulsifier to the filtrate obtained in step 3), and stir evenly;

[0036] Step 5) Subpackage and sterilize: Subpackage and sterilize the liquid obtained in step 4) to obtain clam shellfish beverage C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com