A kind of production equipment of biomass polymer hybrid laminated composite material

A technology for composite materials and production equipment, which is applied in the field of production equipment for biomass polymer hybrid laminated composite materials, and can solve the problem of unsatisfactory physical and mechanical performance indicators such as interfacial toughness and fracture energy of composite materials, weak link structure strength, surface High hardness and other problems, to achieve excellent physical and mechanical properties, speed up paving, and eliminate micro-bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

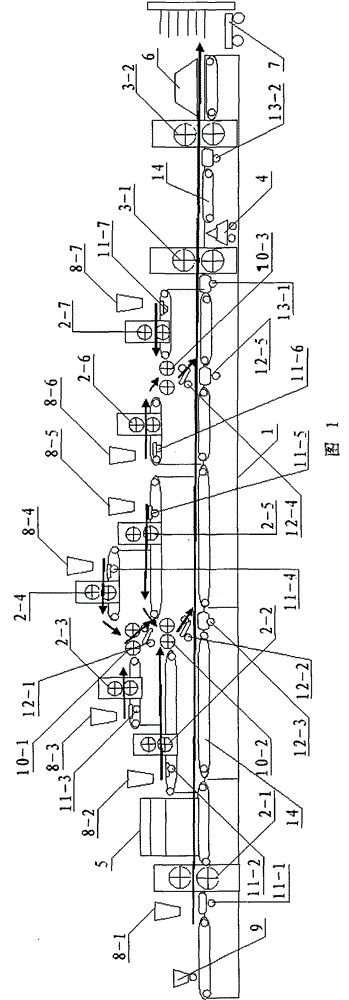

[0007] Specific implementation mode 1: Combination figure 1 This embodiment will be described. This embodiment consists of a three-dimensional composite stand 1, a first paving 159 roll host 2-1, a second paving 159 roll host 2-2, a third paving 159 roll host 2-3, and a fourth paving 159 roll host 2-4, the fifth paving 159 roll host 2-5, the first composite 219 roll host 3-1, the second composite 219 roll host 3-2, infrared automatic cutting machine 4, solid insulation material paving machine 5, Composite material surface vacuum vulcanization device 6, the first automatic spreading device 8-1, the second automatic spreading device 8-2, the third automatic spreading device 8-3, the fourth automatic spreading device 8-4, the fifth Automatic spreading device 8-5, sixth automatic spreading device 8-6, seventh automatic spreading device 8-7, mold plate automatic release agent brushing machine 9, first composite 159 roll 10-1, second Composite 159 roll 10-2, JZO three-phase asynchr...

specific Embodiment approach 2

[0008] Embodiment 2: The equipment of this embodiment is provided with a power transfer box, which can control and adjust the power segment transmission of each roll host and composite roll unit. In order to adjust the main machine of each roller and the composite roller unit to carry out power segmentation control and integrated transmission control of the whole machine according to different production products, to ensure the consistency of the linear motion speed of the entire production line.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 This embodiment will be described. The automatic infrared cutting device provided on the right side of the first composite roll host of this embodiment, when the mold plate carrying the biomass polymer laminated hybrid composite material strip blank passes through the infrared cutting device, the length Under the control of the linear velocity difference of the horizontal movement of the biomass polymer laminated hybrid composite material production equipment, the fixed-length mold plate will produce a gap of 10-20mm between the material-length fixed-length mold plates. When the infrared scanning signal finds this gap , The automatic clamp clamps the gap between the material length and the mold plate, and moves horizontally with the mold plate. At the same time, the cutting tool performs cutting motion along the material length and the mold plate gap. After the cutting is completed, the cutting tool automatically l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com