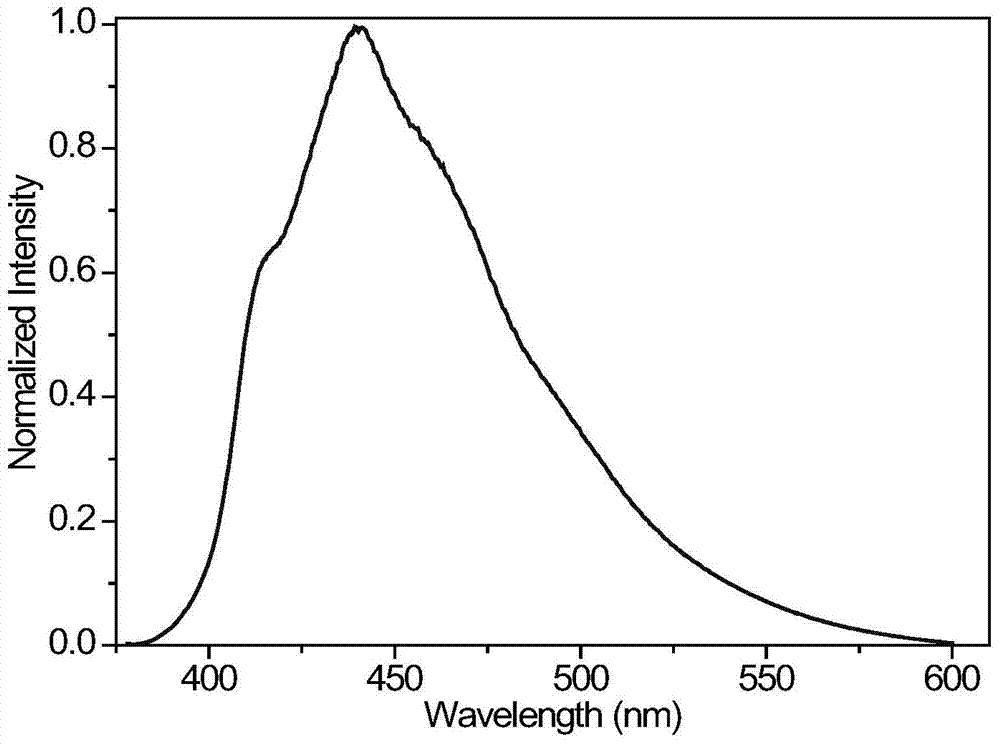

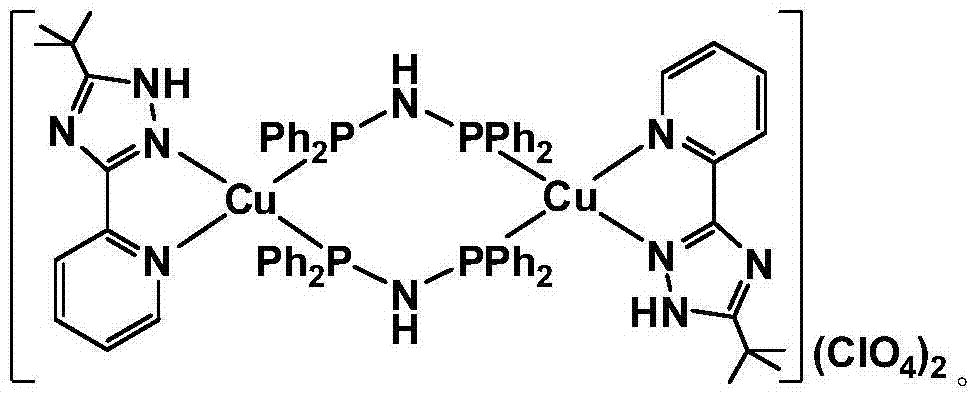

Novel binuclear copper (I) complex blue-light material and method for preparing same

A technology of blue light materials and complexes, applied in the fields of luminescent materials, copper organic compounds, chemical instruments and methods, etc., can solve the problems of few public reports, improve the yield and luminescence quantum efficiency, increase the solubility and the synthesis rate. membranous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

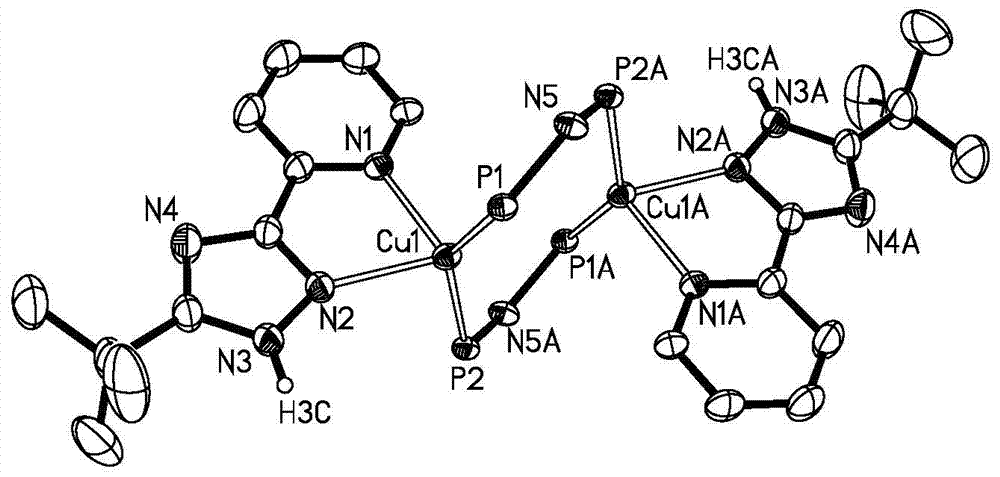

Embodiment 1

[0029] Under an argon atmosphere, equimolar [Cu(MeCN) 4 ](ClO 4 ) (186mg, 0.57mmol) and N,N-bis(diphenylphosphoryl)amine (219mg, 0.57mmol) were stirred in 20mL dichloromethane solvent for 1 hour at room temperature, and then 5 -tert-butyl-3-[2-pyridyl]-1,2,4-triazole ligand (115mg, 0.57mmol), continue to stir the reaction at room temperature for 3 hours, and then evaporate the solvent on a rotary evaporator Dry and recrystallize with dichloromethane (8mL)-diethyl ether (40mL) mixed solvent [volume ratio 1:5]. The crystalline product obtained by recrystallization was filtered, washed 3-4 times with 20 mL of ether, and dried in vacuo to obtain a off-white solid product—a new type of binuclear copper (I) complex blue light material (201 mg, 0.134 mmol). The yield About 47%.

[0030] Electrospray ion mass spectrometry (ESI-MS): mass-to-charge ratio (m / z) 650 [M–(ClO 4 ) 2 ] 2+ ,448[Cu 2 (dppa) 2 ] 2+ ;

[0031] Elemental analysis calculated value (C 70 h 70 Cl 2 Cu 2...

Embodiment 2

[0034] Under an argon atmosphere, copper perchlorate hexahydrate [Cu(ClO 4 ) 2 ·6H 2O] (167mg, 0.45mmol) and excess copper powder (229mg, 3.60mmol) were stirred in 10mL of acetonitrile for 20 minutes, and then 15mL of N,N-bis(diphenylphosphoryl)amine (348mg, 0.90mmol) was added Dichloromethane solution, continue to stir and react for 1 hour, then add 5-tert-butyl-3-[2-pyridyl]-1,2,4-triazole ligand (183mg, 0.90mmol), continue to stir at room temperature After reacting for 3 hours, the solvent was evaporated to dryness on a rotary evaporator after filtration, and recrystallized with a mixed solvent of dichloromethane (10 mL)-diethyl ether (50 mL) [volume ratio 1:5]. The crystalline product obtained by recrystallization was filtered, washed 3-4 times with 25 mL of ether, and dried in vacuo to obtain a off-white solid product—a new type of binuclear copper (I) complex blue light material (278 mg, 0.185 mmol), with a yield of about Be 41%; Analysis and characterization experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com