Environment-friendly energy-saving normal pressure and temperature wet preparation process for refined bismuth

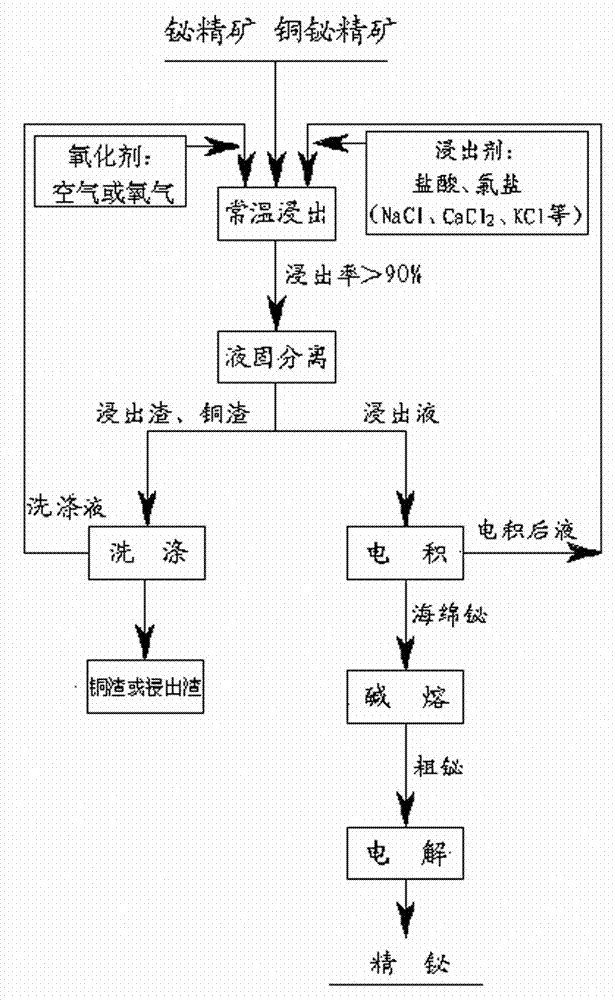

A wet process and energy-saving technology is applied in the field of environmental protection and energy-saving normal temperature and pressure wet process to prepare refined bismuth. It can solve the problems of complex pharmaceuticals, non-environmental protection, and high cost, and achieve high bismuth ore leaching rate, low cost and environmental protection. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The copper-bismuth concentrate is leached under normal temperature and pressure by blowing air into the sodium chloride and hydrochloric acid system.

[0054] Process technical indicators:

[0055] The leaching temperature is at room temperature 25°C, under normal pressure, hydrochloric acid: 90g / L, sodium chloride: 120g / L, liquid-solid ratio 5:1, leaching oxidant is air, leaching time is 4h, basically realizes the complete leaching of Bi, bismuth leaching The yield was 97%, and the pH value of the resulting leachate was 0.5. The composition of the leachate is shown in Table 1-1

[0056] Table 1-1 Leaching liquid composition

[0057] element Bi 3+ Cu 2+ sn 2+ Zn 2+ Fe 3+ Content (g / L) 36.70 2.19 0.23 2.50 0.65

[0058] It can be seen from Table 1-1 that the Bi in the leaching solution 3+ The content is relatively high. Copper in the solution will affect the electrodeposition extraction of bismuth and product quality, therefore...

Embodiment 2

[0063] The bismuth concentrate is leached under normal temperature and pressure by blowing air into the sodium chloride and hydrochloric acid system.

[0064] Process technical indicators:

[0065] The leaching temperature is at room temperature 29°C, under normal pressure, hydrochloric acid: 100g / L, sodium chloride: 110g / L, liquid-solid ratio 5:1, leaching oxidant is air, leaching time is 4 hours, basically realizes the complete leaching of Bi, bismuth The leaching rate is 97.63%, and the pH value of the resulting leachate is 0.5. The composition of the leachate is shown in Table 2

[0066] Table 2 Leaching solution composition

[0067] element Bi 3+ Cu 2+ sn 2+ Zn 2+ Fe 3+ Content (g / L) 31.30 0.26 0.15 1.23 0.62

[0068] It can be seen from Table 2 that the Bi in the leaching solution 3+ The content is relatively high, and its leaching solution directly enters the cyclone electrolysis device for electrowinning to produce sponge bism...

Embodiment 3

[0071] Copper-bismuth concentrate is leached under normal temperature and pressure by blowing air into the calcium chloride and hydrochloric acid system.

[0072] Process technical indicators:

[0073] The leaching temperature is at room temperature 20°C, under normal pressure, hydrochloric acid: 140g / L, calcium chloride: 120g / L, liquid-solid ratio 4:1, leaching oxidant is air, leaching time is 4h, basically realizes the complete leaching of Bi, bismuth leaching The yield was 91.32%, and the pH value of the resulting leachate was 0.5. The composition of the leachate is shown in Table 3-1

[0074] Table 3-1 Leaching solution composition

[0075] element Bi 3+ Cu 2+ sn 2+ Zn 2+ Fe 3+ Content (g / L) 15.61 2.67 0.43 3.15 1.06

[0076] It can be seen from Table 3-1 that the Bi in the leaching solution 3+ The content is relatively low, and the copper in the solution will affect the electrodeposition extraction of bismuth and product quality,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com