Preparation method of Fe3O4/ C nanoparticles

A nanoparticle, fe3o4 technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of low removal efficiency, achieve the effect of uniform size, large adsorption capacity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Fe in the present invention 3 O 4 The preparation method of / C nanoparticles includes the following steps:

[0014] (1) Add 1.35g FeCl 3 ·6H 2 Dissolve O in 40ml ethylene glycol, add 3.6 g NaAc·3H in turn 2 O and 1.0 g polyethylene glycol (PEG-4000), stir for 30min and mix uniformly, pour the solution into a 50ml reactor and react at 200℃ for 8 hours, then cool to room temperature to obtain Fe 3 O 4 Nanoparticles.

[0015] (2) The prepared Fe 3 O 4 Dispersed in 50ml 0.1mol / L HNO 3 Sonicated for 10min, washed with distilled water, and then acidified Fe 3 O 4 Re-disperse in 8ml of 0.5mol / L glucose, ultrasonic, transfer the suspension to the reaction kettle at 170℃ for 4 hours, cool, repeatedly wash with water and ethanol, and dry to obtain Fe 3 O 4 / C Nanoparticles.

Embodiment 2

[0017] Fe 3 O 4 / C Characterization of Nanoparticles

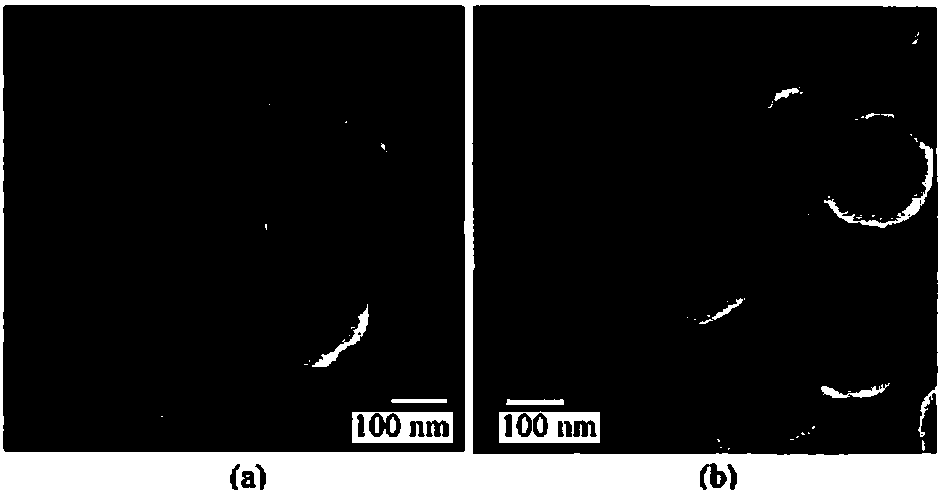

[0018] (1) Fe 3 O 4 And Fe 3 O 4 / C microscopic morphology of nanoparticles

[0019] To Fe 3 O 4 And Fe 3 O 4 / C Nanoparticles for scanning electron microscopy photos (such as figure 1 Shown), in the figure a and b are Fe 3 O 4 And Fe 3 O 4 / C SEM photo, the two kinds of nanoparticles are uniform, the size is about 200nm, Fe 3 O 4 The surface is relatively rough, and the surface becomes smooth after being coated with carbon, indicating the formation of Fe 3 O 4 / C Composite nanoparticles.

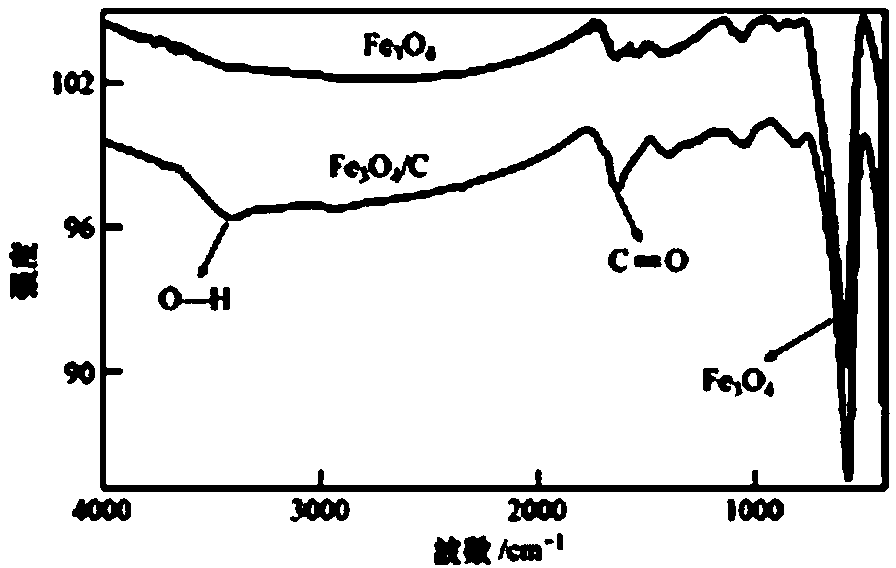

[0020] (2) Fe 3 O 4 And Fe 3 O 4 / C Nanoparticle infrared spectrum

[0021] Using KBr tablet method and Fourier transform infrared spectrometer to measure Fe 3 O 4 And Fe 3 O 4 / C Nanoparticles for infrared spectroscopy analysis (such as figure 2 Shown), where 570 cm -1 The absorption peak is Fe 3 O 4 Characteristic absorption peak, 1631 cm -1 The absorption peak corresponds to the stretching vibration of C=O, 3405 cm -1 The absorption peak cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com