Method for preparing liquid sodium silicate through copper and sulfide tailings

A technology of copper-sulfur tailings and sodium silicate, applied in chemical instruments and methods, solid waste removal, wet separation, etc., can solve the problems of easy collapse and landslides, injury to people, high storage and management costs, etc., to achieve Good social and economic benefits, reduced production costs, wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

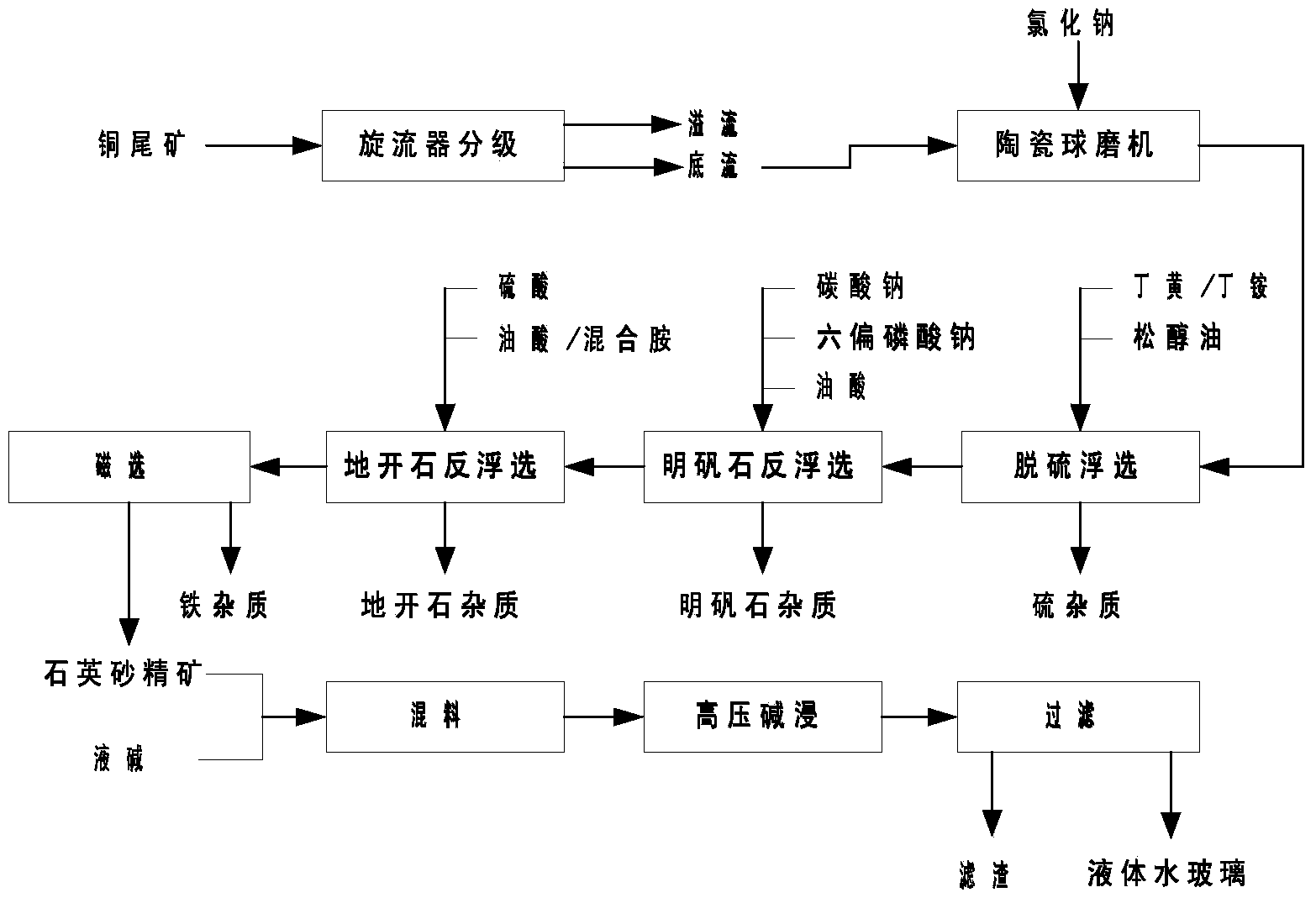

[0021] The copper-sulfur tailings are first graded by a hydrocyclone, the overflow product is directly thrown into the tail, and the underflow product enters the ceramic ball mill. According to the dry weight of the bottom flow of the hydrocyclone per ton, the grinding aid sodium chloride 150g / t is added for grinding , the grinding fineness is 81.62%, the ore discharged from the mill enters the flotation tank, and 40g / t of butyl xanthate, 20g / t of butyl ammonium black medicine, and 20g / t of terpineol oil are added in sequence, and the sulfur impurities are removed by flotation; Add 2500g / t of sodium carbonate to the flotation tailings to adjust the slurry, so that the pH value of the slurry reaches about 8, and then add 500g / t of sodium hexametaphosphate and 150g / t of oleic acid in turn to remove alunite by flotation; alunite flotation Add 1000g / t of dilute sulfuric acid to the tailings to adjust the pulp, so that the pH value of the pulp drops to about 6, then add 50g / t of ole...

Embodiment 2

[0024] The copper-sulfur tailings are first graded by a hydrocyclone, the overflow product is directly thrown into the tail, and the underflow product enters the ceramic ball mill. According to the dry weight of the bottom flow of the hydrocyclone per ton, 200g / t of grinding aid sodium chloride is added for grinding , the grinding fineness is 85.46%, the ore discharged from the mill enters the flotation tank, and butyl xanthate 50g / t, butyl ammonium black medicine 30g / t, terpineol oil 30g / t are added in turn, and sulfur impurities are removed by flotation; Add 3000g / t of sodium carbonate to the flotation tailings to adjust the slurry, so that the pH value of the slurry reaches about 9, then add 600g / t of sodium hexametaphosphate and 200g / t of oleic acid in turn, and remove the alunite through flotation; alunite flotation Add 1200g / t of dilute sulfuric acid to the tailings to adjust the slurry, so that the pH value of the slurry will drop to about 5, then add 60g / t of oleic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com