Preparation method of nanopore chip with plasmon resonance scattering response function

A plasmon resonance and nanopore technology, applied in the direction of material excitation analysis, etc., to achieve the effect of simple steps, low cost, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a nanopore chip with plasmon resonance scattering response, the steps comprising:

[0031] (1) Selection of chip substrate

[0032] Choose Thick 100 A silicon wafer is used as a chip substrate, and an insulating material with a thickness of 5 nm is deposited on the front side of the silicon wafer, and the insulating material is silicon nitride; there is no insulating material on the reverse side of the silicon wafer.

[0033] (2) Fabrication of chips

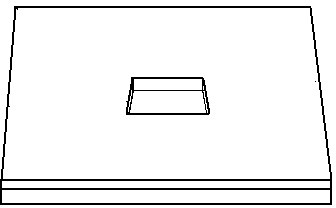

[0034] Etch a side length of 100mm on the reverse side of the silicon wafer in step (1) by wet etching The square area is etched until the insulating material silicon nitride is exposed; the etched square area is the nanoporous chip film (see figure 1 ).

[0035] (3) Nanopore etching

[0036] Place the chip described in step (2) in a plasma cleaner for 5 minutes to wash away the pollutants in the film of the nanoporous chip; then place the chip backside up in a vacuum chamber, when the vacuum...

Embodiment 2

[0040] A method for preparing a nanopore chip with plasmon resonance scattering response, the steps comprising:

[0041] (1) Selection of chip substrate

[0042] Choose Thick 300 A silicon wafer is used as the chip substrate, and an insulating material with a thickness of 50 nm is deposited on the front side of the silicon wafer, and the insulating material is aluminum oxide; there is no insulating material on the reverse side of the silicon wafer.

[0043] (2) Fabrication of chips

[0044] Use wet etching to etch a side length of 300mm on the reverse side of the silicon wafer in step (1). The square area is etched until the insulating material alumina is exposed; the etched square area is the nanoporous chip film (see figure 1 ).

[0045] (3) Nanopore etching

[0046] Place the chip described in step (2) in a plasma cleaner for 5 minutes to wash away the pollutants in the film of the nanoporous chip; then place the chip backside up in a vacuum chamber, when the vacuum ...

Embodiment 3

[0050] A method for preparing a nanopore chip with plasmon resonance scattering response, the steps comprising:

[0051] (1) Selection of chip substrate

[0052] Choose Thick 500 A silicon wafer is used as the chip substrate, and an insulating material with a thickness of 100 nm is deposited on the front side of the silicon wafer, and the insulating material is silicon dioxide; there is no insulating material on the reverse side of the silicon wafer.

[0053] (2) Fabrication of chips

[0054] Use wet etching to etch a side length of 500mm on the back side of the silicon wafer in step (1). The square area is etched until the insulating material silicon dioxide is exposed; the etched square area is the nanoporous chip film (see figure 1 ).

[0055] (3) Nanopore etching

[0056] Place the chip described in step (2) in a plasma cleaner for 5 minutes to wash away the pollutants in the film of the nanoporous chip; then place the chip backside up in a vacuum chamber, when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com