Non-stick pan free of fluoride and manufacturing method thereof

A non-stick pan and fluoride technology, which is applied in the direction of ion implantation plating, application, coating, etc., can solve the problems of PTFE non-stick pans such as hidden dangers to human health, testing heavy metal migration, and short service life. To achieve the effect of safety and environmental protection in the preparation process, long service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

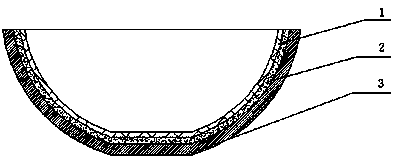

[0022] A fluoride-free non-stick pan and a preparation method thereof. like figure 1 As shown, the transition layer 2 is first coated on the inner surface of the aluminum alloy pan base 3, and the material of the transition layer 2 is alumina; then the aluminum alloy pan base 3 coated with the transition layer 2 is ultrasonically cleaned in an acetone solution, and then Dehydration treatment with absolute ethanol, drying; finally, using multi-arc ion plating technology, depositing a hard ceramic layer 1 of TiC nanostructure on the transition layer 2 of the dried aluminum alloy pot base 3, and making a non-fluoride-free sticky pan.

[0023] The thickness of the transition layer 2 is 10-30 μm.

[0024] The cleaning time of the ultrasonic cleaning is 10-40 minutes.

[0025] The process parameters of the hard ceramic layer 1 of the deposited TiC nanostructure are: negative bias voltage is 0V; C 2 h 2 The flow rate is 0.15~0.18L / min; the Ar flow rate is 0.02~0.03L / min; the tar...

Embodiment 2

[0028] A fluoride-free non-stick pan and a preparation method thereof. like figure 1 As shown, the inner surface of the aluminum alloy pan base 3 is first coated with a transition layer 2, and the material of the transition layer 2 is aluminum nitride; then the aluminum alloy pan base 3 coated with the transition layer 2 is ultrasonically cleaned in an acetone solution , then dehydrated with absolute ethanol, and dried; finally, using multi-arc ion plating technology, a hard ceramic layer 1 of TiC nanostructure is deposited on the transition layer 2 of the dried aluminum alloy pot base 3 to obtain a fluoride-free non-stick pan.

[0029] The thickness of the transition layer 2 is 20-40 μm.

[0030] The cleaning time of the ultrasonic cleaning is 20-50 minutes.

[0031] The process parameters of the hard ceramic layer 1 of the deposited TiC nanostructure are: negative bias voltage is 1 ~ 150V; C 2 h 2 The flow rate is 0.18~0.22L / min; the Ar flow rate is 0.03~0.04L / min; the ...

Embodiment 3

[0034] A fluoride-free non-stick pan and a preparation method thereof. like figure 1 As shown, the transition layer 2 is first coated on the inner surface of the aluminum alloy pan base 3, and the material of the transition layer 2 is alumina; then the aluminum alloy pan base 3 coated with the transition layer 2 is ultrasonically cleaned in an acetone solution, and then Dehydration treatment with absolute ethanol, drying; finally, using multi-arc ion plating technology, depositing a hard ceramic layer 1 of TiC nanostructure on the transition layer 2 of the dried aluminum alloy pot base 3, and making a non-fluoride-free sticky pan.

[0035] The thickness of the transition layer 2 is 30-50 μm.

[0036] The cleaning time of the ultrasonic cleaning is 30-60 minutes.

[0037] The process parameters of the hard ceramic layer 1 of the deposited TiC nanostructure are: negative bias voltage is 150 ~ 300V; C 2 h 2 The flow rate is 0.22~0.25L / min; the Ar flow rate is 0.01~0.02L / min;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com