Sintered compact and amorphous film

A technology of sintered body and amorphous film, applied in the directions of oxide conductors, non-metallic conductors, ion implantation plating, etc., can solve the problems of small refractive index, small specific resistance, and different composition systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

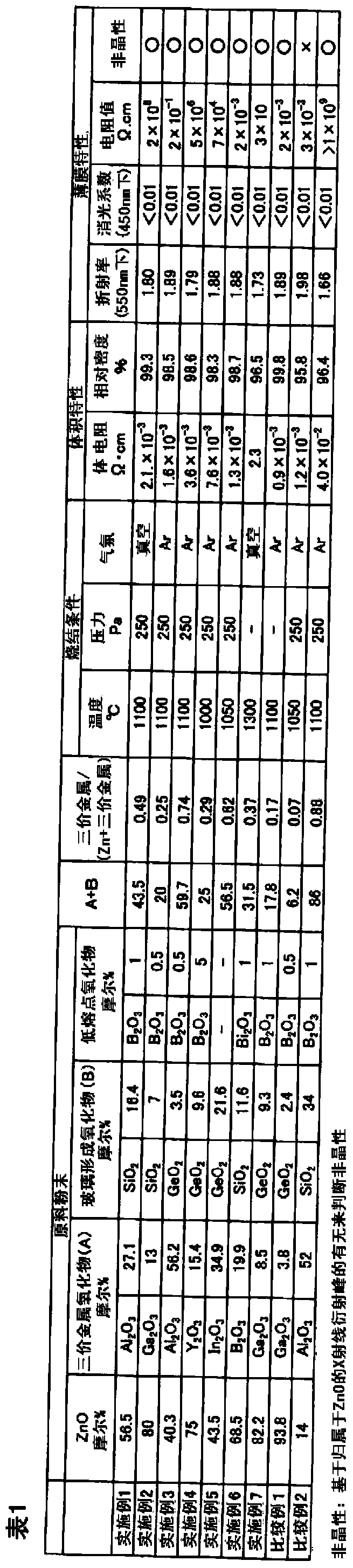

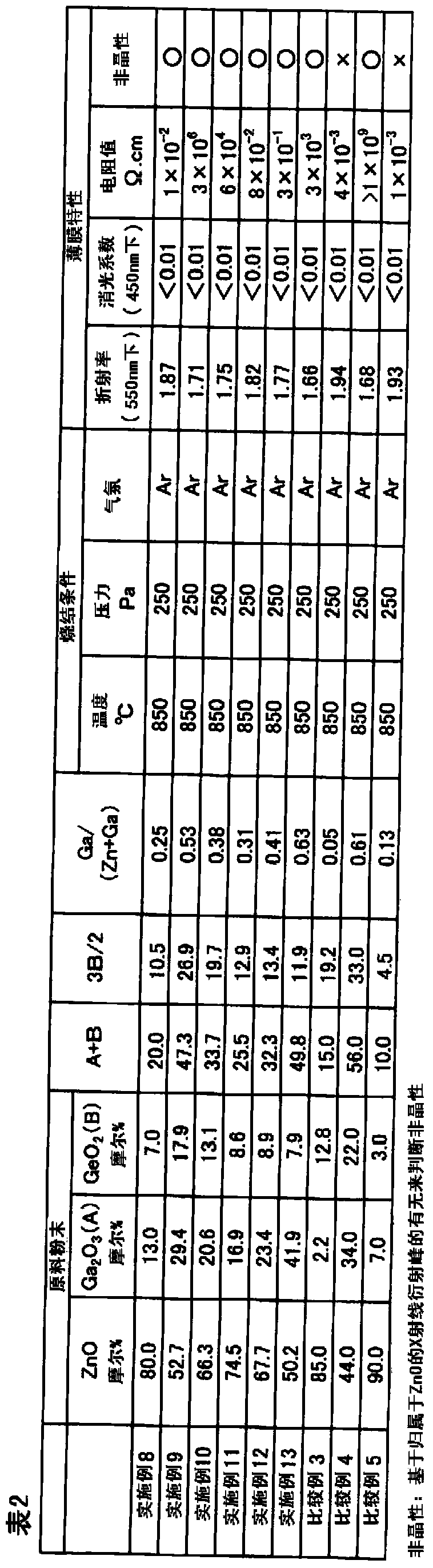

[0067] Prepare ZnO powder, Al 2 o 3 Powder, SiO 2 powder and B as a low-melting oxide 2 o 3 powder. Then, these powders were formulated into the proportions described in Table 1, and after they were mixed, the powder materials were placed in a vacuum at a temperature of 1100°C and a pressure of 250kgf / cm 2 Hot pressing sintering under the conditions.

[0068] Then, this sintered body was finished into a sputtering target shape by machining. The volume resistance and relative density of the obtained target were measured, and the results are shown in Table 1. The relative density reached 99.3%, the volume resistance was 2.1 mΩ·cm, and stable DC sputtering was possible.

[0069] In addition, sputtering was performed using the above-mentioned finished target. Set to DC sputtering, sputtering power 500W, containing 2 volume % O 2 Under the sputtering condition of the Ar gas pressure of 0.5Pa, the film is formed as film thickness. The amorphousness, refractive index (wavele...

Embodiment 2

[0072] Prepare ZnO powder, Ga 2 o 3 Powder, SiO 2 powder and B as a low-melting oxide 2 o 3 powder. Then, these powders were formulated into the proportions described in Table 1, and after they were mixed, the powder materials were heated in an argon atmosphere at a temperature of 1100° C. and a pressure of 250 kgf / cm 2 Hot pressing sintering under the conditions. Then, this sintered body was finished into a sputtering target shape by machining. The volume resistance and relative density of the obtained target were measured, and the results are shown in Table 1. The relative density reached 98.5%, the volume resistance was 1.6 mΩ·cm, and stable DC sputtering was possible.

[0073] In addition, sputtering was performed under the same conditions as in Example 1 using the above-mentioned finished target, and the amorphous property, refractive index (wavelength: 550 nm), volume resistivity, and extinction coefficient (wavelength: 450 nm) of the film-formed sample were measur...

Embodiment 3

[0075] Prepare ZnO powder, Al 2 o 3 Powder, GeO 2 powder and B as a low-melting oxide 2 o 3 powder. Then, these powders were formulated into the proportions described in Table 1, and after they were mixed, the powder materials were heated in an argon atmosphere at a temperature of 1100° C. and a pressure of 250 kgf / cm 2 Hot pressing sintering under the conditions. Then, this sintered body was finished into a sputtering target shape by machining. The volume resistance and relative density of the obtained target were measured, and the results are shown in Table 1. The relative density reached 98.6%, the volume resistance was 3.6 mΩ·cm, and stable DC sputtering was possible.

[0076] In addition, sputtering was performed under the same conditions as in Example 1 using the above-mentioned finished target, and the amorphous property, refractive index (wavelength: 550 nm), volume resistivity, and extinction coefficient (wavelength: 450 nm) of the film-formed sample were measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com