Method for producing liquid compound fertilizer by using biogas slurry

A technology of compound fertilizer and biogas slurry, which is applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of increasing fertilizer production cost, limiting production speed, and secondary pollution, so as to improve agricultural utilization value, increase production efficiency, and avoid loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

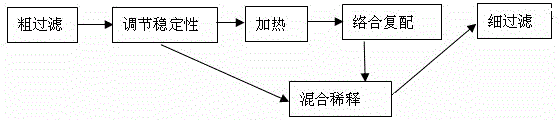

Image

Examples

Embodiment 1

[0036] Example 1 Preparation of a widely adaptable flush-release fertilizer

[0037] The fertilizer formula is shown in Table 1:

[0038] Table 1 Formula of widely applicable flush-release fertilizer

[0039] raw material weight percentage Biogas slurry 45% Potassium humate 10% Urea 30% superphosphate 20% Potassium chloride 5%

[0040] Preparation of flush-release fertilizers as described in the table above:

[0041] a. Use a vibrating screening machine to screen and filter the biogas slurry to remove solid particles with a particle size larger than 0.25mm in the biogas slurry;

[0042] b. According to the ratio of 5kg citric acid and 2kg polypropylene glycol per ton of fertilizer, add citric acid as a flocculant and polypropylene glycol as a defoaming agent to the biogas slurry, and then use nitric acid to adjust the pH of the biogas slurry to 5.5-8.5; During the process of adding flocculant and defoamer, conventional e...

Embodiment 2

[0049] Example 2 A special foliar fertilizer for tomatoes

[0050] The fertilizer formula is shown in the table below:

[0051] Table 3 Formula of special foliar fertilizer for tomatoes

[0052] raw material name weight percentage Biogas slurry 90% Urea 4% superphosphate 2% Potassium chloride 1% Potassium humate 1% Ferrous sulfate 0.5% Magnesium sulfate 0.5% copper sulfate 0.2% Manganese sulfate 0.3% Zinc sulfate 0.2% Borax 0.3%

[0053] Preparation of the foliar fertilizers recorded in the table above:

[0054] a. Use a vibrating screening machine to screen and filter the biogas slurry to remove solid particles with a particle size larger than 0.25mm in the biogas slurry;

[0055]b. According to the ratio of 5kg citric acid and 2kg polypropylene glycol per ton of fertilizer, add citric acid as a flocculant and polypropylene glycol as a defoamer to the biogas slurry, and then adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com