Scumbling type polyurethane waterproof paint and usage method thereof

A polyurethane waterproof and polyurethane technology, applied in polyurea/polyurethane coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of unfavorable saving of raw materials, inability to achieve waterproof effect, poor adhesion, etc., to improve the environment Adaptability and aging resistance, excellent physical and mechanical properties and adhesion, beneficial to driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

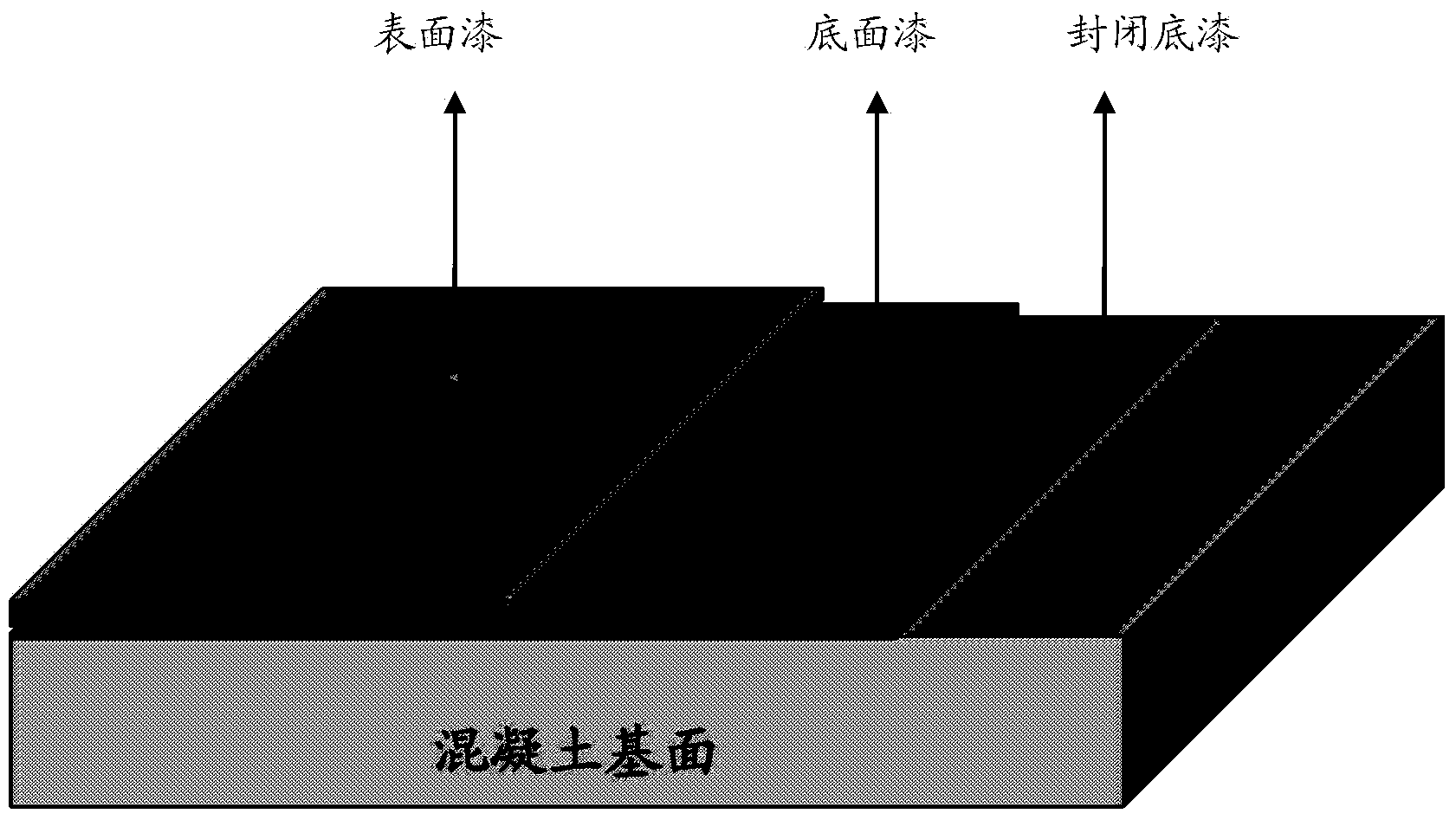

[0049] Example 1 Thin-coated polyurethane waterproof paint used as waterproof layer for high-speed railway ballastless track concrete bridge deck

[0050] 1. The component ratio of thin-coated polyurethane waterproof paint:

[0051] Sealing primer: Epoxy sealing primer (produced by Langfang Santong Chemical Industry Co., Ltd.).

[0052] Thin-coated polyurethane waterproof primer (PPU-M1): includes A1 component and B1 component, of which:

[0053] Component A1 contains: 60g polyether polyol (including 45.7g polyether 4000 and 14.3g polyether 330N), 13g sharp titanium dioxide, 14.9g filler (including 5.0g talcum powder, 9.35g barium sulfate, 0.05g medium pigment and 0.5g bentonite), 2.1g coalescent (including 1.3g modified acrylic resin (accelerator), 0.1g hydrophobic siloxane (defoamer) and 0.7g acrylate polymer (MCK-3058 , leveling agent)) and 10g solvent (ethylene glycol ether acetate);

[0054] Component B1 contains: 60g MDI semi-prepolymer and 20g solvent (ethylene gly...

Embodiment 2

[0073] Example 2 Thin-coated polyurethane waterproof paint used as waterproof layer for high-speed railway ballastless track concrete bridge deck

[0074] 1. The component ratio of thin-coated polyurethane waterproof paint:

[0075] Sealing primer: polyurethane sealing primer (produced by Langfang Santong Chemical Industry Co., Ltd.).

[0076] Thin-coated polyurethane waterproof primer (PPU-M1): includes A1 component and B1 component, of which:

[0077] Component A1 contains: 40g polyether polyol (including 30.5g polyether 4000 and 9.5g polyether 330N), 28g sharp titanium dioxide, 19.9g filler (including 5.0g talcum powder, 14.35g barium sulfate, 0.05g medium pigment and 0.5g bentonite), 2.1g coalescent (including 1.3g modified acrylic resin (accelerator), 0.1g hydrophobic siloxane (defoamer) and 0.7g acrylate polymer (MCK-3058 , leveling agent)) and 10g solvent (ethylene glycol ether acetate);

[0078] B1 component contains: 40g MDI semi-prepolymer.

[0079] Thin-coated...

Embodiment 3

[0092] Example 3 Thin-coated polyurethane waterproof paint used as waterproof layer for high-speed railway ballastless track concrete bridge deck

[0093] 1. The component ratio of thin-coated polyurethane waterproof paint:

[0094] Sealing primer: Epoxy sealing primer (produced by Langfang Santong Chemical Industry Co., Ltd.).

[0095] Thin-coated polyurethane waterproof primer (PPU-M1): includes A1 component and B1 component, of which:

[0096] Component A1 contains: 50g polyether polyol (including 38g / kg polyether 4000 and 12g / kg polyether 330N), 24g sharp titanium dioxide, 13.9g filler (including 5.0g talcum powder, 8.35g barium sulfate, 0.05g medium pigment and 0.5g bentonite), 2.1g film-forming aids (including 1.3g modified acrylic resin (accelerator), 0.1g hydrophobic siloxane (defoamer) and 0.7g acrylate polymer (MCK -3058, leveling agent)) and 10g solvent (ethylene glycol ether acetate);

[0097] Component B1 contains: 50g MDI semi-prepolymer and 10g solvent (eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com