Expanded perlite insulated shell with heat-reflecting cavity and method for producing same

A technology of expanded perlite and a production method, which is applied in the direction of heat insulation protection of pipelines, pipeline protection, mechanical equipment, etc., can solve the problems of not being able to fully utilize the heat reflection of aluminum foil, achieve the effect of improving heat preservation and energy saving, reduce the overall weight, and facilitate The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

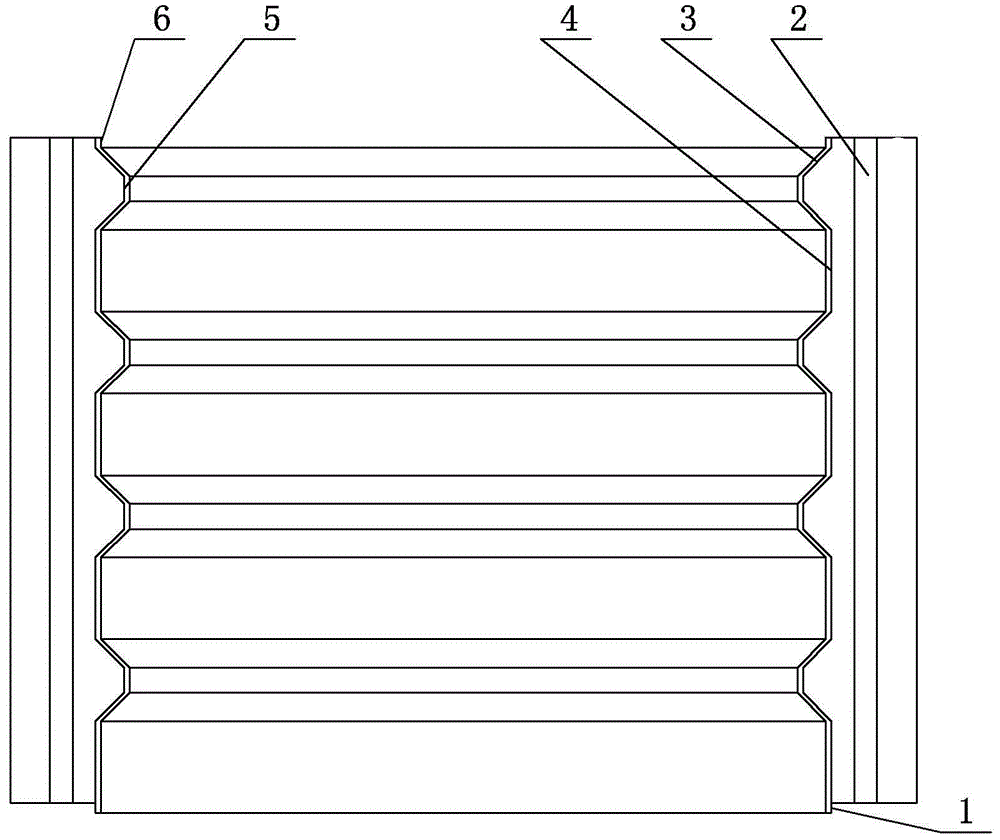

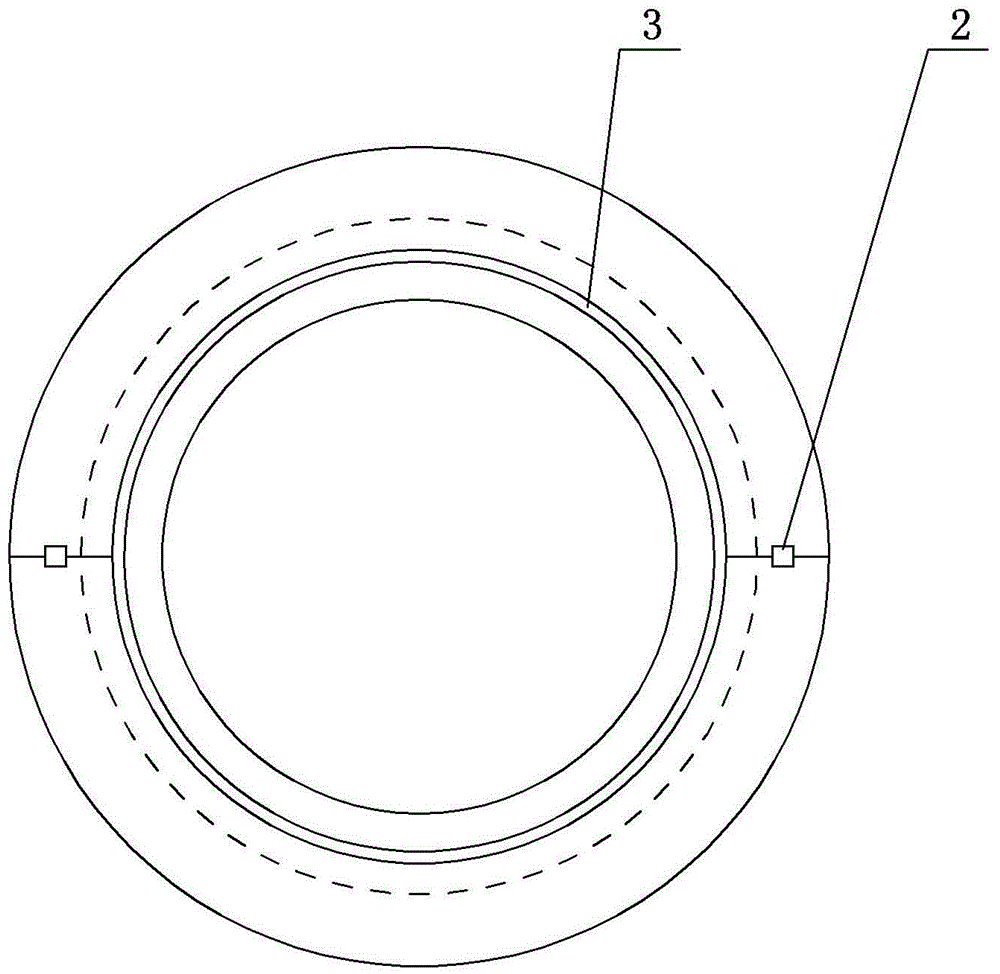

[0029] As shown in the figure, the expanded perlite heat-insulating shell of the present invention includes a heat-insulating shell body, the inner wall of the longitudinal section of the heat-insulating shell body has a concave-convex structure, and the surface of the inner wall is provided with a heat-reflecting film 3 。

[0030] The heat reflective film 3 Aluminum foil or silver white coating (can be aluminum powder coating).

[0031] The heat insulating shell body is composed of two or three arc-shaped split bodies butt joints, and the arc-shaped split body butt joint surfaces are correspondingly provided with sealing grooves 2 , sealing groove 2 A first sealing member is arranged in the enclosed space. Set sealing groove 2 And the first seal not only plays a good role in sealing and heat insulation, but also solves the problem of the seal breaking away from the seam after installation, and reduces the impact of damage to the heat insulation tube shell b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com