Preparation method of radix rehmanniae polysaccharide liposome

A polysaccharide and liposome technology of Rehmannia glutinosa is applied in the directions of liposome delivery, non-central analgesics, antipyretics, etc. The effect of encapsulation efficiency, saving raw materials and improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 Preparation of RGPL by ethanol injection method

[0059] Weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 0.1g of Tween 80 and dissolve them in 10mL of absolute ethanol, and dissolve them fully by ultrasonic; -1 The PBS (pH 7.0) solution of rehmannia polysaccharide was slowly introduced into the former, kept at 50 °C and continued to shake for 30 min; placed in a 250 mL round bottom flask, evaporated under reduced pressure at 60 °C to remove ethanol, and then placed in an ultrasonic cell pulverizer for ultrasonic treatment (intensity 50 %, open at 2.5s, stop at 2.5s, and act for 1h), so that RGP can be fully and evenly fused into liposomes, and at the same time make the particle size of RGPL more uniform, so as to obtain RGPL suspension; then squeeze them separately Microporous membranes with a pore size of 0.45 μm and 0.22 μm were repeated three times each to obtain the RGPL solution. Store at 4°C.

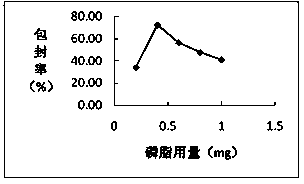

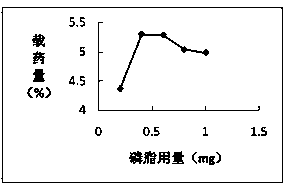

[0060] According to calculation, the encapsulatio...

Embodiment 2

[0061] Embodiment 2 film dispersion method prepares RGPL

[0062] Weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 0.1g of Tween 80 and dissolve it in 10mL of chloroform and methanol (1:1) solution, sonicate to fully dissolve it; place it in a 250mL round bottom flask, and evaporate it under reduced pressure at 60°C Organic solvent, when a uniform film is formed on the wall of the flask, introduce 20mL of -1 The PBS (pH7.0) solution of rehmannia polysaccharide was evaporated under reduced pressure at 60°C to elute the film on the bottle wall; hydrated at 25°C for 1 hour; s stop, act for 1h), so that RGP is fully and uniformly fused into liposomes, and also makes the particle size of RGPL more uniform, so as to obtain RGPL suspension; microporous membrane, each repeated three times to obtain the RGPL solution. Store at 4°C.

[0063] According to calculation, the encapsulation efficiency of RGPL prepared by this method is 32.560%.

Embodiment 3

[0064] Embodiment 3 Ammonium sulfate gradient method prepares RGPL

[0065] Weigh 0.4g of soybean lecithin, 0.05g of cholesterol and 0.1g of Tween 80 and dissolve them in 10mL of absolute ethanol, and ultrasonically dissolve them fully; under the vibration of a water bath shaker at 50°C, introduce the former into 10mL of 10% ammonium sulfate solution, Then put it in a 250mL round bottom flask, evaporate the organic solvent under reduced pressure at 60°C; dialyze in PBS (pH7.0) for 24h; -1 The PBS (pH 7.0) solution of rehmannia polysaccharide was slowly introduced into the former, kept at 50°C and continued to shake for 30 minutes; then placed in an ultrasonic cell pulverizer for ultrasonic treatment (intensity 50%, 2.5s on, 2.5s off, 1h), so that RGP Fully and evenly fused into liposomes, and at the same time make the particle size of RGPL more uniform, so as to obtain RGPL suspension; then squeeze it through microporous membranes with pore diameters of 0.45 μm and 0.22 μm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com