Nizatidine composition tablet

A technology for nizatidine and a composition, which is applied in the field of medicine and medicine manufacturing, can solve the problems of inconvenient use, carrying and transportation, storage inconvenience, restrictions on clinical use and promotion, affecting the absorption effect of patients, etc., and achieves low cost and accurate dosage. , easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

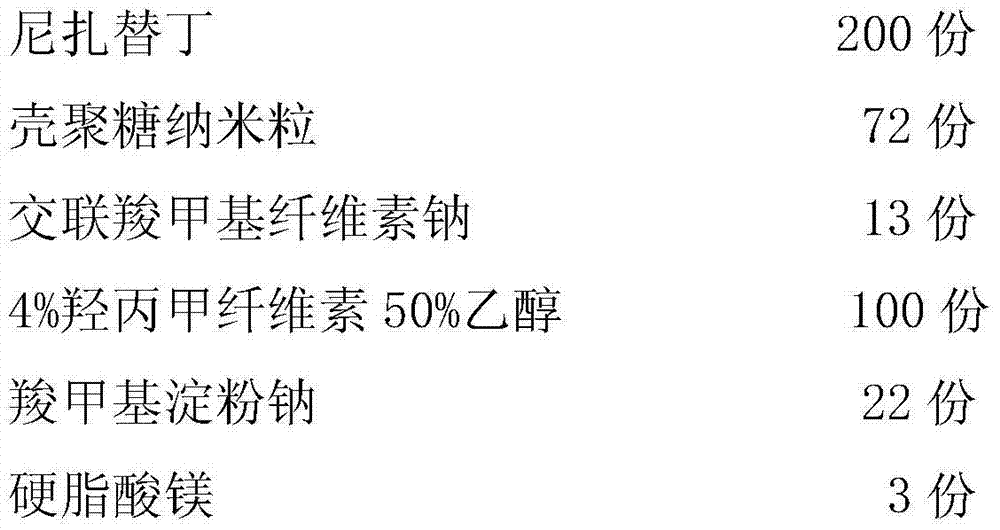

[0037] Nizatidine was used as the raw material to investigate the effects of the dosage of various excipients on the angle of repose, hardness, appearance, disintegration, friability and dissolution of the drug. The dosage of excipients in each prescription is shown in Table 1.

[0038] Sieve the raw materials and auxiliary materials separately, and set aside: Nizatidine, chitosan nanoparticles, hypromellose, pregelatinized starch, croscarmellose sodium, carboxymethyl starch sodium, stearic acid Magnesium was mixed according to the prescription amount, the angle of repose was measured, and the hardness, appearance, weight difference, disintegration, friability, and dissolution were measured after tableting. The results are shown in Table 2. Among them, the determination methods of hardness, appearance, weight difference, disintegration, friability and dissolution refer to the second appendix of "Chinese Pharmacopoeia" 2005 edition. Appearance: visual inspection; hardness, dis...

Embodiment 2

[0045] Prepare nizatidine granules with prescription 4 of Example 1, take three parts and place each in a weighed flat weighing bottle, place them under the conditions of RH43%, RH59%, and RH70% respectively, place 1, 3, After 5 days, they were weighed separately to investigate the influence of different humidity on the drug, and the absorption rate of the particles was calculated. The results are shown in Table 3.

[0046] Table 3 moisture absorption rate test results

[0047] condition

[0048] It can be seen from the results in Table 3 that under the humidity condition of RH70%, the moisture absorption weight gain increases significantly, and under the condition of RH59% humidity, the moisture absorption weight gain does not change significantly. Therefore, the space humidity must be controlled below RH59% during the preparation process.

Embodiment 3

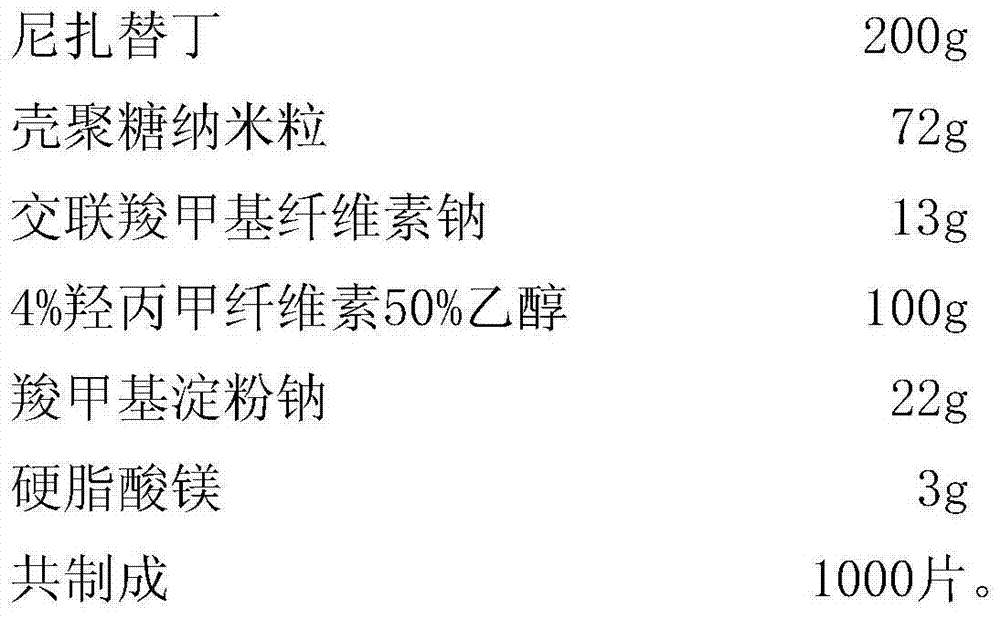

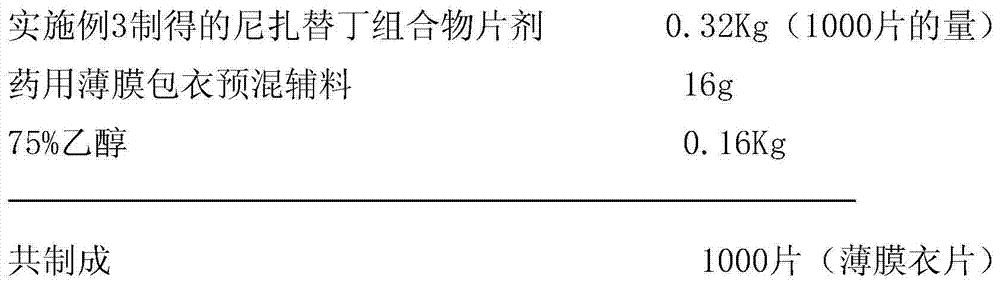

[0049] Embodiment 3: Nizatidine composition tablet of the present invention

[0050]

[0051]Preparation method: respectively pass nizatidine, chitosan nanoparticles, croscarmellose sodium and carboxymethyl starch sodium through 80 mesh sieves, then 200g of nizatidine, 72g of chitosan nanoparticles Mix evenly with 13g of croscarmellose sodium, add 100g of 4% hypromellose 50% ethanol soft material, pass through a 20-mesh sieve and make granules, control the humidity below RH59%, will make The granules are dried at 50-60°C, passed through a 18-mesh sieve, added with 22g of sodium carboxymethyl starch and 3g of magnesium stearate, mixed evenly, punched and pressed into tablets with a Φ11mm shallow arc surface, and obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com