Power cold combined supplying system suitable for recycling temperature varying heat source

A heat source and co-supply technology, applied in energy-saving heating/cooling, machines using waste heat, refrigerators, etc., can solve problems such as inability to work, no implementation methods are given, and no consideration of thermal energy temperature matching, etc., to enhance adaptability, Simplify the condensation process equipment and solve the complex effect of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

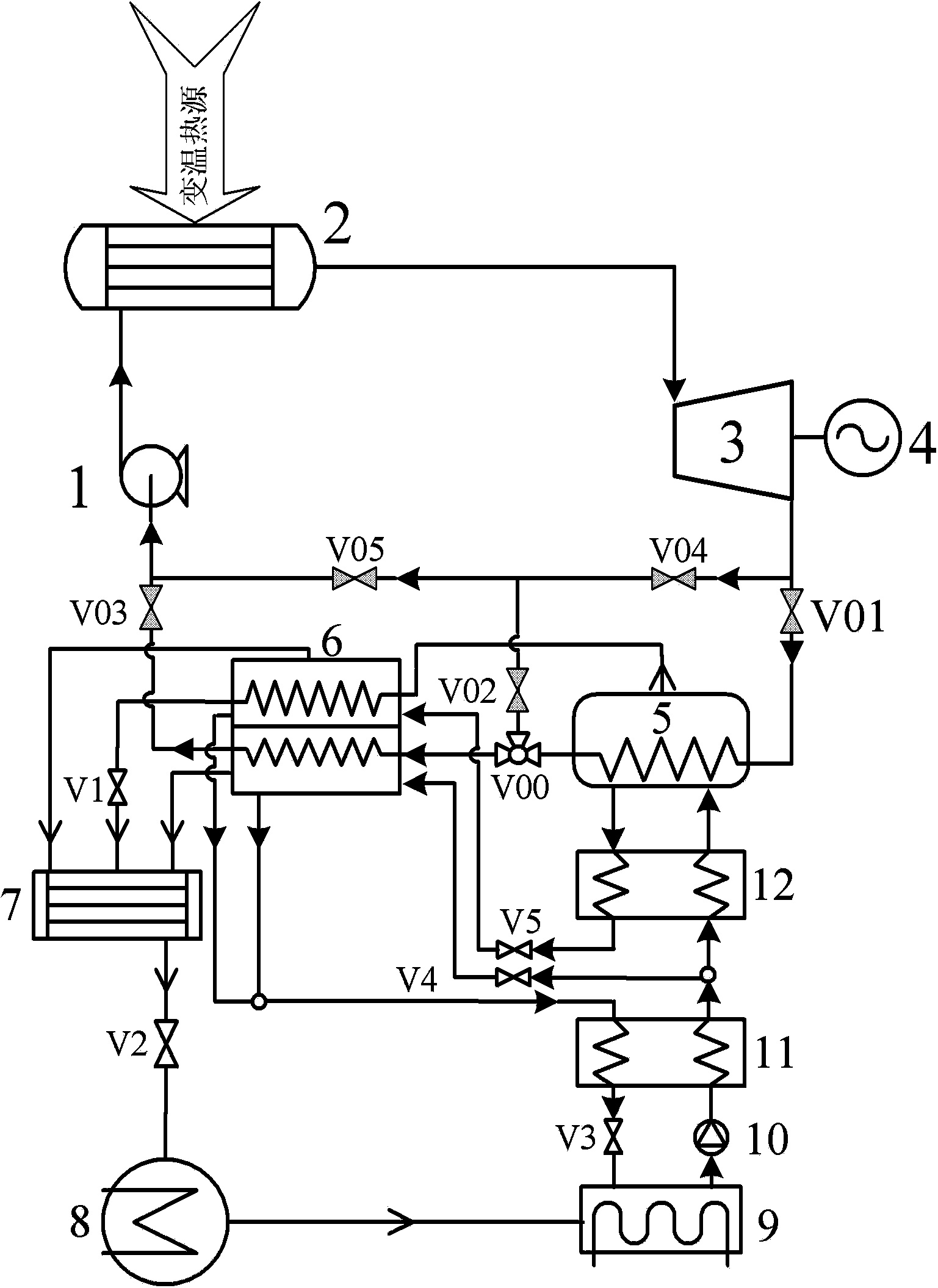

[0045] figure 2 It is a structural schematic diagram of a power-cooling combined power supply system suitable for recovering variable temperature heat sources according to the first embodiment of the present invention. In this power-cooling combined power supply system, valves V02, V04, and V05 are closed, valves V01, V03 are opened, and ammonia water The mixed working fluid flows through the high-pressure generator and the low-pressure generator in turn, and the condensation discharge drives the operation of the single- and double-effect composite lithium bromide absorption refrigerator. When the temperature of the variable temperature heat source is low, it is necessary to increase the temperature range of the phase change evaporation of the ammonia water mixture, so that the ammonia water Rankine cycle can match the temperature of the variable temperature waste heat source. For the ammonia-water mixture with a large temperature range in the condensation process, in order t...

Embodiment 2

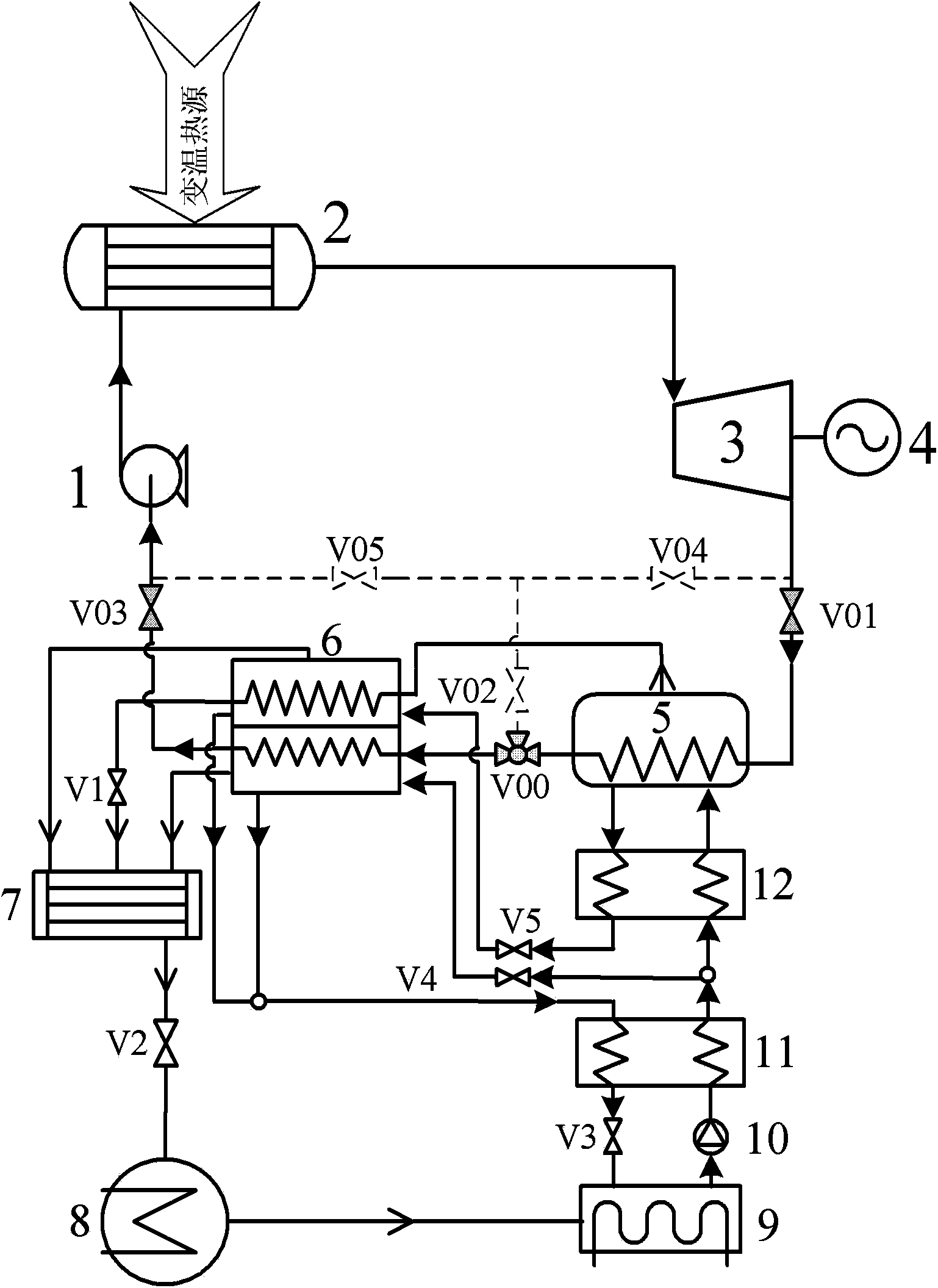

[0048] image 3 It is a schematic structural diagram of a power-cooling combined power supply system suitable for recovering variable temperature heat sources according to the second embodiment of the present invention. In this power-cooling combined power supply system, valves V01 and V05 are closed, valves V02, V03 and V04 are opened, and ammonia water The mixed working fluid only flows through the low-pressure generator, and the single-effect lithium bromide absorption refrigerator is driven by the ammonia water Rankine cycle. The condensation process of the ammonia water Rankine cycle is: outlet of turbine 3 → mixed low-pressure generator 6 → inlet of pump 1. Among them, the low-pressure generator is the condenser of the ammonia rankine cycle, and also the solution generator of the lithium bromide absorption refrigerator. The condensation heat of the ammonia rankine cycle drives the lithium bromide absorption refrigerator to work. In the lithium bromide absorption refrige...

Embodiment 3

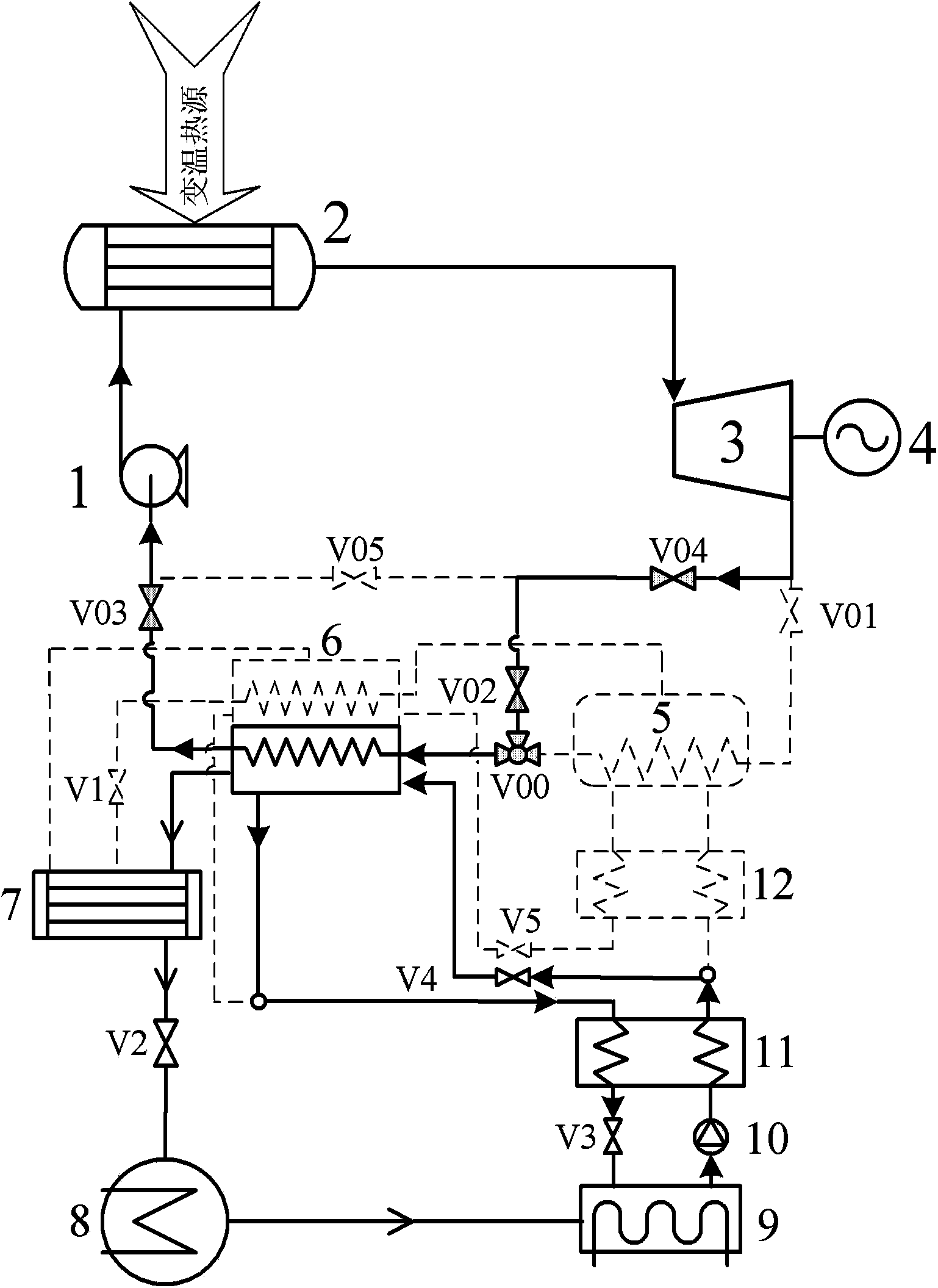

[0050] Figure 4 It is a schematic structural diagram of a power-cooling combined supply system suitable for recovering variable temperature heat sources according to the third embodiment of the present invention. In this power-cooling combined supply system, valves V03 and V04 are closed, valves V01, V02 and V05 are opened, and the new The combined supply and cooling system uses the ammonia water Rankine cycle to drive the double-effect lithium bromide absorption refrigerator to operate. The condensation process of the ammonia water Rankine cycle is: outlet of turbine 3 → high pressure generator 5 → inlet of pump 1. Among them, the high-pressure generator is the condenser of the ammonia rankine cycle, and also the high-pressure generator of the lithium bromide absorption refrigerator. The ammonia-water mixture in the ammonia rankine cycle is condensed in the high-pressure generator 5 to release heat, and the condensation heat is used to drive the lithium bromide absorption re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com