Composite material for supercapacitor and preparation method thereof

A technology of supercapacitors and composite materials, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors, etc. It can solve the problems of few reports and achieve the effect of wide source of raw materials and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

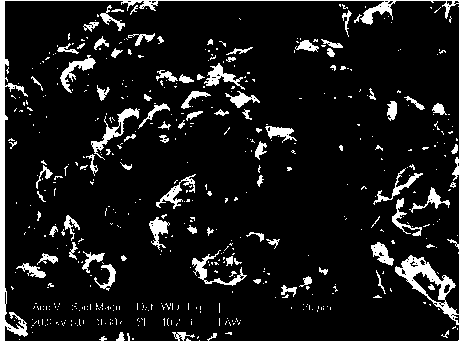

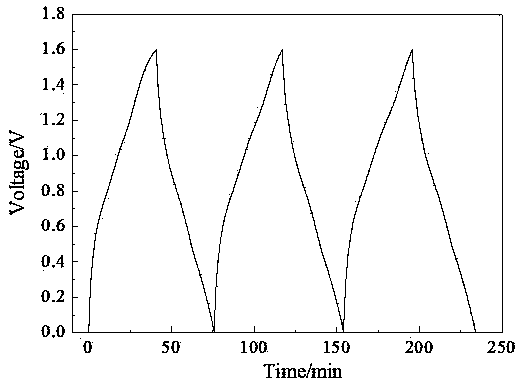

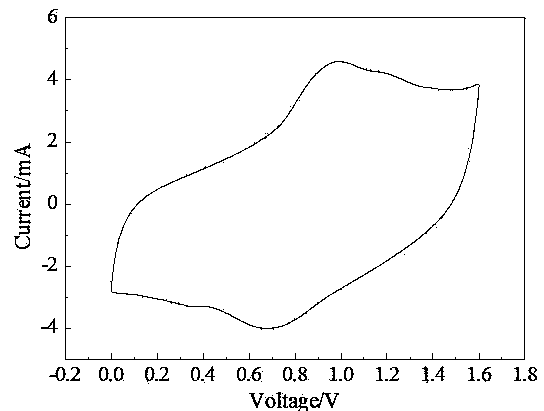

[0019] Such as Figure 1-3 As shown, weigh manganese carbonate, citric acid, zinc carbonate and activated carbon, manganese carbonate and citric acid are mixed uniformly in deionized water by magnetic stirring, add activated carbon water dispersion liquid with 20% manganese mass dispersed by ultrasound, and heat up to 60 °C , constant temperature reaction for 50min, add zinc carbonate, continue to stir for 2h, the ratio of manganese carbonate to zinc carbonate is 1:6. After cooling to room temperature, the obtained product was precipitated and filtered, washed with deionized water, and vacuum-dried at 60°C to constant weight; the obtained product was calcined at 700°C for 2 hours to obtain a composite material of zinc-manganese composite metal oxide and activated carbon. Composite materials, binder PTFE, and conductive agent VGCF are used to make positive electrodes, and activated carbon, binder PTFE, and conductive agents are used to make negative electrodes. The middle is se...

Embodiment 2

[0021] Weigh ferric oxide, activated carbon and zinc oxide in equal amounts and put them into a ball mill tank with a material to ball mass ratio of 1:20, and ball mill for 4 hours to obtain a composite material precursor. The precursor was calcined at 700°C for 2 hours to obtain a composite material of zinc-iron composite metal oxide and activated carbon. Composite materials, binder PTFE, and conductive agent VGCF are used to make positive electrodes, and activated carbon, binder PTFE, and conductive agents are used to make negative electrodes. The middle is separated by a diaphragm, and 1M zinc sulfate electrolyte is added to make a supercapacitor.

Embodiment 3

[0023] Weigh zinc nitrate and cobalt nitrate to make an aqueous solution according to the metering ratio, stir and mix with activated carbon dispersion liquid with 30% cobalt mass, and stir for 2 hours in a nitrogen atmosphere, then add sodium hydroxide, and control the reaction time for 5 minutes. The product was washed and dried, and the obtained composite material precursor was calcined at 600° C. for 1 hour to obtain a composite material of zinc-cobalt composite metal oxide and activated carbon. Composite materials, binder PTFE, and conductive agent VGCF are used to make positive electrodes, and activated carbon, binder PTFE, and conductive agents are used to make negative electrodes. The middle is separated by a diaphragm, and 1M zinc sulfate electrolyte is added to make a supercapacitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com