Method for producing 2-chloropyridine and 2,6-dichloropyridine with inorganic solvent process

A technology of inorganic solvent and dichloropyridine, which is applied in the field of producing 2-chloropyridine and 2 by inorganic solvent method, can solve the problems of low economic benefit, by-products, and difficult source of 2-hydroxypyridine, and achieve high economic value and easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

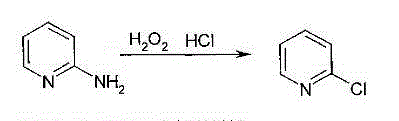

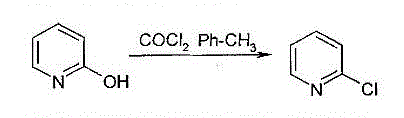

Problems solved by technology

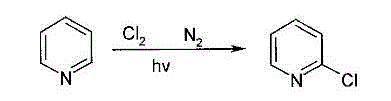

Method used

Image

Examples

Embodiment 1

[0030] Pyridine and deionized water are mixed according to the mass ratio of 0.8:1 to prepare 20Kg of pyridine aqueous solution, and the pyridine aqueous solution is vaporized to make vaporized product; the vaporized product and chlorine gas are mixed according to the mass ratio of 1.5:1. The amount of feed is sent to the quartz reactor at a rate of 5Kg / h to make it react under the irradiation of an ultraviolet lamp. The reaction pressure is controlled at -0.3 to -0.5KPa, and the reaction temperature is controlled at 310-340°C. cooling to obtain the reaction solution; neutralize the pH value of the reaction solution to 10 with sodium hydroxide solution, then distill the reaction solution to obtain a mixed solution of organic matter and water; leave the mixed solution to separate layers, take out the organic phase, and then The organic phase was rectified under the condition of -0.08 to -0.085MPa, and the fractions in the temperature range of 110-113°C were collected to obtain 9...

Embodiment 2

[0032] Pyridine and deionized water are mixed according to the mass ratio of 0.3:1 to prepare 20Kg of pyridine aqueous solution, and the pyridine aqueous solution is vaporized to make vaporized product; the vaporized product and chlorine gas are mixed according to the mass ratio of 5:1 to obtain The amount of feed is sent to the quartz reactor at a rate of 8Kg / h to make it react under the irradiation of an ultraviolet lamp. The reaction pressure is controlled at -0.3 to -0.5KPa, and the reaction temperature is controlled at 260-290°C. cooling to obtain the reaction solution; neutralize the pH value of the reaction solution to 10 with sodium hydroxide solution, then distill the reaction solution to obtain a mixed solution of organic matter and water; leave the mixed solution to separate layers, take out the organic phase, and then The organic phase was rectified under the condition of -0.08 to -0.085MPa, and the fractions in the temperature range of 110-113°C were collected to o...

Embodiment 3

[0034] Pyridine and deionized water are mixed according to the mass ratio of 0.5: 1 to prepare 20Kg of pyridine aqueous solution, and the pyridine aqueous solution is vaporized to make vaporized product; the vaporized product and chlorine gas are mixed according to the mass ratio of 3: 1 to obtain The amount of feed is sent to the quartz reactor at a rate of 6Kg / h to make it react under the irradiation of an ultraviolet lamp. The reaction pressure is controlled at -0.3 to -0.5KPa, and the reaction temperature is controlled at 280-300°C. cooling to obtain the reaction solution; neutralize the pH value of the reaction solution to 10 with sodium hydroxide solution, then distill the reaction solution to obtain a mixed solution of organic matter and water; leave the mixed solution to separate layers, take out the organic phase, and then The organic phase was rectified under the condition of -0.08 to -0.085MPa, and the fractions in the temperature range of 110-113°C were collected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com