Polyvinyl alcohol fiber reinforced polyurethane grouting reinforcement material and preparation method thereof

A polyvinyl alcohol fiber, grouting reinforcement technology is applied in the field of polyurethane grouting reinforcement materials reinforced with high-strength and high-modulus polyvinyl alcohol ultra-short fibers, which can solve the problem of unsuitable industrial mass production and poor fluidity of the slurry. Good performance, small penetration radius, etc., to achieve the effect of enhancing the performance of reinforcement, easy grouting operation, and strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

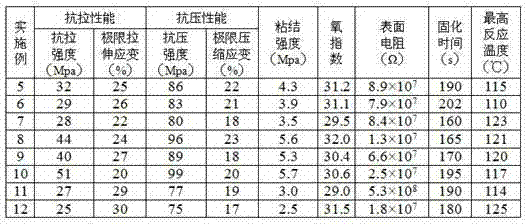

Examples

Embodiment 1

[0054] Select polyvinyl alcohol fibers with a length of 4.0 mm and a diameter of 14.0 μm, breaking strength ≥ 10 cN / dtex, and initial modulus ≥ 220 cN / dtex, and modify the polyvinyl alcohol fibers according to the following steps.

[0055] Step a), take the polyvinyl alcohol fiber and place it in a watch glass, put it in a drying oven, bake it at 120°C for 30 minutes, remove the wetting agent on the surface of the fiber, and then cool it down to room temperature naturally;

[0056] Step b), mix absolute ethanol and silane coupling agent KH550 according to the volume ratio of 200:1 to obtain a mixed solution, add the polyvinyl alcohol fibers treated in step a) into the mixed solution, and ultrasonically treat at 40°C After 30min, the fibers were filtered out from the solution after standing;

[0057] In step c), the polyvinyl alcohol fibers treated in step b) are dried at 80° C. for 180 minutes to obtain modified polyvinyl alcohol fibers, which are cooled for later use.

Embodiment 2

[0059] Select polyvinyl alcohol fibers with a length of 5.6 mm and a diameter of 14.0 μm, breaking strength ≥ 10 cN / dtex, and initial modulus ≥ 220 cN / dtex, and modify the polyvinyl alcohol fibers according to the following steps.

[0060] Step a), take the polyvinyl alcohol fiber and place it in a watch glass, put it in a drying oven, bake it at 130°C for 20 minutes, remove the wetting agent on the surface of the fiber, and cool it down to room temperature naturally;

[0061] Step b), mix absolute ethanol and silane coupling agent KH550 uniformly according to the volume ratio of 180:1 to obtain a mixed solution, add the polyvinyl alcohol fibers treated in step a) into the mixed solution, and ultrasonically treat at 30°C After 90min, the fiber was filtered out from the solution after standing still;

[0062] In step c), the polyvinyl alcohol fibers treated in step b) are dried at 90° C. for 130 minutes to obtain modified polyvinyl alcohol fibers, which are cooled for later use...

Embodiment 3

[0064] Select polyvinyl alcohol fibers with a length of 7.0 mm and a diameter of 14.0 μm, breaking strength ≥ 10 cN / dtex, and initial modulus ≥ 220 cN / dtex, and modify the polyvinyl alcohol fibers according to the following steps.

[0065] Step a), put the polyvinyl alcohol fiber in a watch glass, put it in a drying oven, bake it at 140°C for 10 minutes, remove the wetting agent on the surface of the fiber, and cool it down to room temperature naturally;

[0066] Step b), mix absolute ethanol and silane coupling agent KH550 according to the volume ratio of 165:1 to obtain a mixed solution, add the polyvinyl alcohol fibers treated in step a) into the mixed solution, and ultrasonically treat at 50°C After 120min, the fiber was filtered out from the solution after standing still;

[0067] In step c), the polyvinyl alcohol fibers treated in step b) are dried at 100° C. for 80 minutes to obtain modified polyvinyl alcohol fibers, which are cooled for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com